Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Swords Precision is a company that creates custom parts in a machine called the lathe. The lathe is a powerful tool for cutting and shaping various materials enabling the fabrication of highly precise components for a wide variety of applications. This is called precision machining, and it is crucial in ensuring that parts fit and function together nicely.

Attention to detail is very important when you use a lathe machine because precision is very important. A single error can render a component completely inoperable. For instance, if something is too large or too tiny, it may not work well with other things, and this can lead to issues in machines or instruments. That is also the reason Swords Precision of page one always works with the best materials and the most modern lathe machines in order to ensure that every single item we produce is perfect and of the quality we demand.

Swords Precision has extensive experience in the production of lathe machined parts of all shapes and sizes. Be it a basic bolt that is required to fix everything or a more complex component that is required for specialized equipment, we can manufacture it easily! Our experts are adept at a range of materials to produce stunning and functional parts.

An other big aspect of this process is measuring and inspecting the size of the part during the manufacturing process. This step is critical as it allows us to validate that the part is being manufactured correctly and to the specifications it is supposed to adhere to. We then have measuring tools to verify the dimensions, etc.

Once we understand our clients’ requirements, we can use our lathe machining knowledge and skills to design the right part for their design project. This can be everything from designing a new shape altogether to using a certain material to make the part stronger or more effective. Our clients love when we take on even the most difficult requirements and deliver a product they are happy with.

Well, Swords Precision goes through quite a lengthy lathe machining process. First, you need to choose the best materials for the job. Material selection is critical to the performance and longevity of the part. We then use our lathe machines to sculpt the product into the final shape. We do not use cutting tools, or techniques to help with precision and accuracy.

We refer back to our part drawing and taking guidance from our inspection report wherein we do dimensions measuring and checking, ensuring that we achieve our quality standards for the part. As we check everything continuously, we catch any errors early and can make corrections before the part is completed. And last, we complete the section and post it to our consumer. This means making sure the part is clean, polished, and ready to go.

Our team of engineers is always available, ready to lathe machining parts promptly to your inquiries. They are highly skilled and have the know-how to solve your concerns. Custom parts with high precision tolerances: +/-0.01 mm, Special area: +/-0.005 mm.

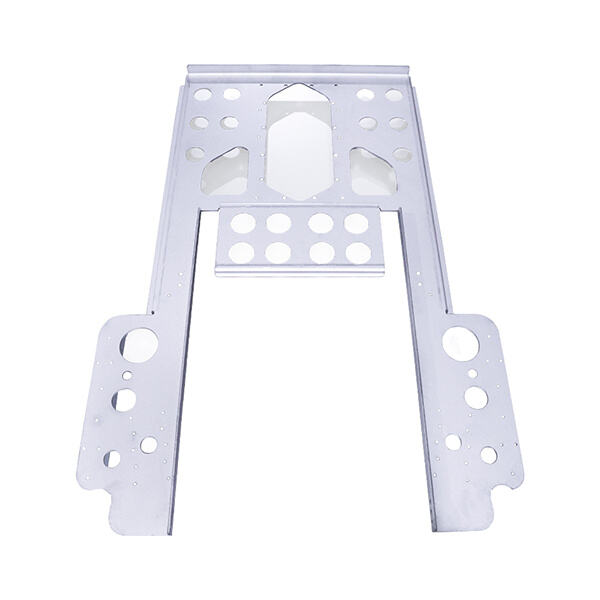

Our equipment for production includes 3-axis, 4-axis, 5 axis up to 6-axis equipment. We offer a variety of processing capabilities that include turning, milling and drilling, grinding and EDM lathe machining parts. We deal with a wide range of materials, including copper, brass, aluminum, steel, stainless steel, composites, plastics, crafting parts fitting to any industrial requirement.

We have ISO9001 certificate, ISO14001, ISO45001 lathe machining parts ISO13485, aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

lathe machining parts offer OEM and ODM service The minimum order quantity is 1 piece Quotes are sent within three hours Production samples take 1 to 3 days while bulk delivery takes between 7 and 14 days Our production capacity for the month is more than 300 000 pieces

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog