Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sondag Gesluit

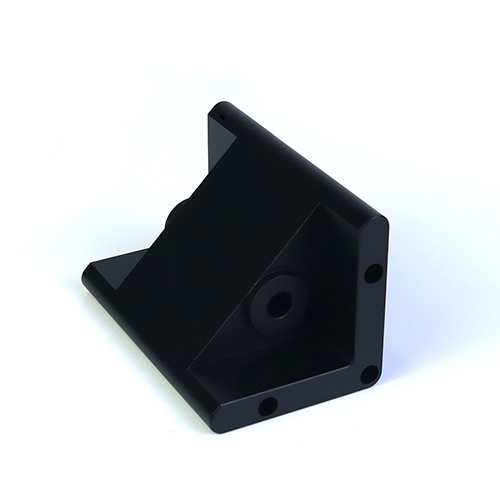

Tipe: Brokkel, BORING, Etsering / Chemiese Werking, Laser Werking, Fras, Ander Werkmateriaal Diens, Draai, Draad EDM, Vinnige Prototipering

Modelnommer: OEM

Sleutelwoord:CNC Werkmateriaal Diens

Materiaal: rosteenvry staal

Verwerkingsmetode : Cnc maal

Levertyd:7-15 dae

Kwaliteit:Hoë Kwaliteit

Sertifikaat:ISO9001:2015/ISO13485:2016

MOQ:1Stukke

Produk Oorsig

Gespesialiseerde bediening van servo-freswerking is 'n hoë-prestasie vervaardigingsuitrusting wat gevorderde tegnologie integreer, ontwerp om die bewerkingsbehoeftes van verskeie industrieë vir hoë-nakwelling en komplekse vormkomponente te voldoen. Dit integreer presies meganiese strukture, gevorderde servo-beheersisteme en intelligente bewerkingsprogrammatuur, wat gebruikers een-stap-gespesialiseerde bewerkingsdienste bied van ontwerp tot eindprodukte.

Kenmerk

Deur hoë-nakwelling servo-stelsels, hoogmate van gespesialiseerde bewerkings, gevorderde frestechnologie, intelligente bewerkings en kwaliteitsversekeringsprosedures te integreer, het dit 'n wydverspreide materiaalverenigbaarheid en voldoen aan die presisie-vervaardigingsbehoeftes van verskeie velde soos lughawe en motorindustrie.

Materiaalverenigbaarheid

aluminium Legering

Voor aluminiumliggaamstowwe, kan ons toerusting die voordele van hoogsnelheidskerf en hoog-naukeurigheid bewerkings volledig benut. Tydens die verwerking van aluminiumliggaamsstrukturele komponente vir lughawe of aluminiumliggaamwiele vir motorvoertuie, is dit maklik om te handel met die lae hartheid en hoë warmtegeleiings eienskappe van aluminiumliggaams, effektiewe en hoë-kwaliteit bewerkings behaal.

titaniumlegering

Titaniumliggaam is 'n moeilik-te-bewerk materiaal, maar ons toerusting kan die uitdagings in titaniumliggaam bewerkings doeltreffend oorkom deur geoptimaliseerde kerfparameters en gevorderde werktuig tegnologie. In die lughaweverbintenis, kan ons servo-millingtoerusting die bewerkingsakkuraatheid en oppervlak kwaliteit vir titaniumliggaamkomponente verseker, soos sleuteldele van motors, wat hul hoë-sterkte en hoë-temperatuur weerstand vereiste voldoen.

Roesvrystaal en liggaamstaal

Wanneer hoë-sterkte- en hoë-hardheidmateriale soos roestvrystaal en legeringstaal verwerkseld word, kan die hoë-draairossel van die toerusting en gevorderde hulpmiddelpadbeplanning 'n stabiele verwerkingproses verseker. Sowel roestvrystalondertalle in die voedselverwerkingsbedryf asook legeringstaalonderdelle in die meganiese vervaardigingsveld kan presies gesny word.

toepassingsgebied

1. Lughawe

In die lughemvaarbedryf verskaf ons hoë-naukeurige snydienste vir die vervaardiging van lugvaartmotors, vlerkstrukture, satellietkomponente en meer. Hierdie komponente het uiterst hoë vereistes vir kwaliteit en akkuraatheid, en ons produkte verseker dat elke onderdeel streng lughemvaarnorms voldoen, wat sekerheid bied vir die veiligheid en prestasie van lugvaartuie.

2. Motorvervaardiging

Die outomotiefbedryf is een van ons belangrike kliëntegroepe. Ons verskaf gespesialiseerde oplossings vir die verwerking van outomoottoring cilinderblokke, transmissies, wielhubbies, remstelsels en ander komponente. Deur hoë-nakkerigheids frasverwerking is die kwaliteit en prestasie van outomoottekomponente verbeter, wat helpende carmanufacturiers in staat stel ligterwigtige en hoë-prestasieprodukte te bereik, en wat die mark se vraag vir energiebesparing, omgewingsbeskerming en veiligheid in die outomotiefbedryf bevredig.

3. Mediese Toestelle

Die kwaliteit en akkuraatheid van mediese toestelle is direk verwant aan die veiligheid van pasiënte se lewens. Ons verskaf presies verwerking vir die vervaardiging van ortopediese implante, chirurgiese instrumente, mediese toerustingshusse en meer. Hierdie komponente moet streng vereistes vir biokompatibiliteit, dimensionele akkuraatheid en oppervlak-kwaliteit bereik. Ons op maat gemaaide servomeulprodukte verseker dat elke mediese toestelkomponent die hoë standaarde van die mediese bedryf bereik.

4. Elektroniese kommunikasie

In die veld van elektroniese kommunikasie verskaf ons dienste vir die verwerking van komponente vir kommunikasiebasisstationtoerusting, slimfone, rekenaars en ander produkte. Veral vir sleutelkomponente soos warmtesinkies, presisie-vorms en chipverpakkingstrukture kan ons toerusting hoë-akkuraatheid en hoë-effektiewe verwerking bereik, wat die vereistes van elektroniese kommunikasieprodukte vir miniaturisering, hoë prestasie en hoë warmteverspreiding ontmoet.

5. Vormskepingsvervaardiging

Die vormskepingsvervaardigingsbedryf het uiterst hoë eise aan noukeurigheid en die verwerking van komplekse vorms. Ons gespesialiseerde servo-borselprodukte kan hoë-kwaliteit verwerkingsservices vir die vervaardiging van verskeie tipes vormskepe bied, soos inspuitvormskepe, drukgietvormskepe, presvormskepe, ens. Deur middel van meerverbindingsverwerking en hoë-noukeurige borseltegnologie is ons in staat om hoë-kwaliteit vormskepe te vervaardig, wat hul akkuraatheid en lewensduur verseker, en betroubare vormskeepsteun vir die produksie van plastiek- en metaalprodukte bied.

V: Watter materialen kan verwerk word?

A: Ons gespesialiseerde servo-freseiningsuitrusting het uitstekende verwerkingvermoë vir verskeie materialen, insluitend maar nie beperk tot metaalmaterialen soos aluminiumliggaam, titaniumliggaam, roestvry staal, legeringsstaal, asook sommige hoë-werkprestasie ingenieursplastieke. Vir verskillende materialen sal ons verwerkingparameters aanpas en toepaslike snyinstrumente kies op grond van hul hardheid, taaiheid, warmtegeleiendheid en ander eienskappe om die verwerkingskwaliteit te verseker. Byvoorbeeld, wanneer moeilik-te-verwerk materiaal soos titaniumliggaam verwerk word, gebruik ons spesiale snystrategieë en instrumente om hul verwerkingsprobleme te oorkom.

V: Hoe lyk die aanpassingsproses?

A: Eerstens, jy verskaf ons die ontwerptekeninge, tegniese vereistes en die verwagte gebruik van die dele. Ons ingenieursspan sal hierdie inligting evalueer en met jou kommunikeer om die besonderhede te bevestig. Daarna sal ons 'n gedetailleerde masjineringsplan ontwikkel gebaseer op jou vereistes, insluitend die seleksie van toepaslike gereedskap en vaste klemme, die bepaling van die masjineringsvolgorde en snyparameters. Tydens die prosessering sal ons regelmatig voortgangsvoerback aan jou verskaf. As nodig is, kan ons die prosesseringplan op grond van jou voerback aanpas. Ten slotte word 'n streng kwaliteitsinspeksie uitgevoer nadat die prosessering voltooi is om seker te maak dat die produk jou vereistes voldoen voor aflewering.

V: Hoe lank neem dit om 'n komplekse deel te prosesseer?

A: Die tyd wat vereis word om 'n komplekse deel te prosesseer, hang af van verskeie faktore, insluitend die kompleksiteit, grootte, materiaaleienskappe en benodigde presisie van die deel. Algemeen gesproke, vir dele van matige kompleksiteit en grootte, deur ons gespesialiseerde bewerkingsbediening te gebruik, kan die verwerkingstyd wissel van 'n paar ure tot talle ure. Ons sal u 'n ruwe ramingsverslag oor die verwerkingstyd gee wanneer die verwerkingplan ontwikkel word, en sal probeer om die verwerkingstyd soveel as moontlik te verkort deur die proses te optimaliseer.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privaatheidsbeleid—Blog