كيف يُحوِّل ضمان الجودة العالي معالجة المعادن الحديثة

Nov.27.2024

كيف يُحوِّل ضمان الجودة العالي معالجة المعادن الحديثة

أهمية معالجة المعادن الورقية

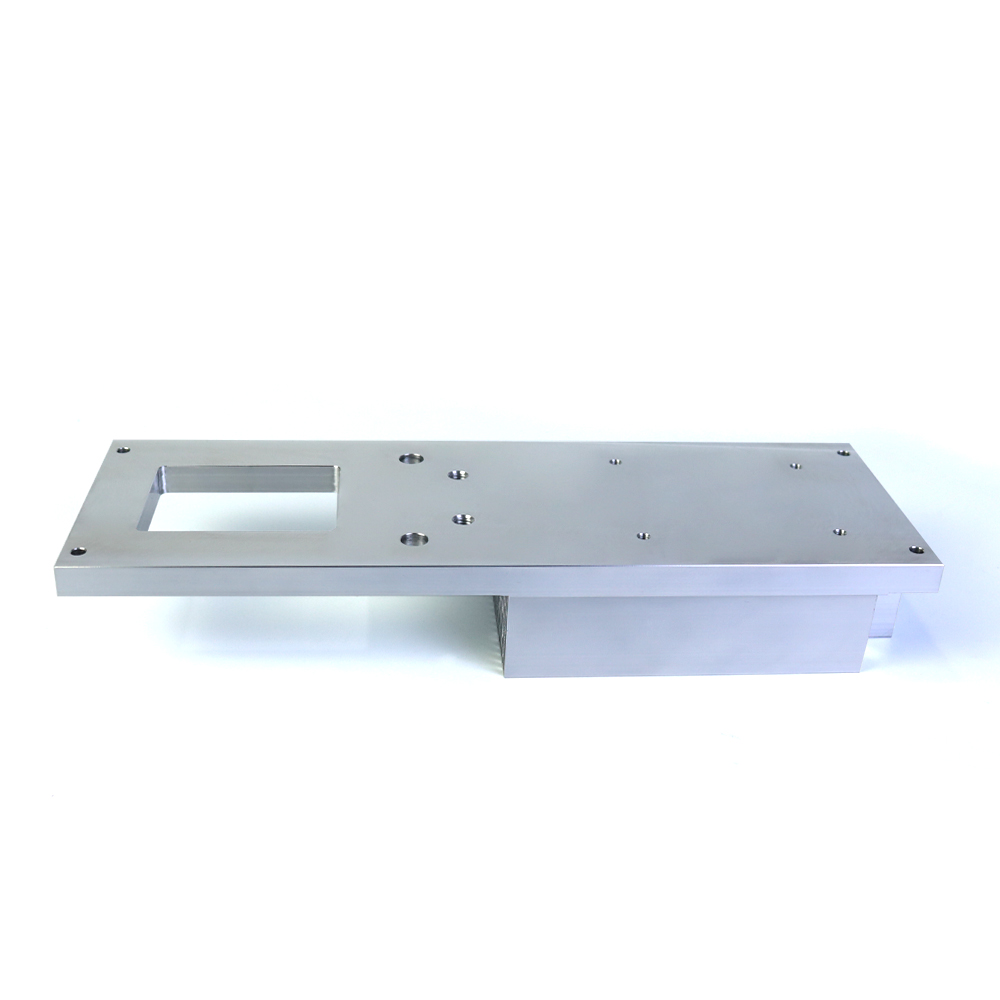

ابدأ بالتأكيد على أهمية معالجة المعادن الورقية لعدد واسع من الصناعات مثل السيارات، الإلكترونيات، البناء، والطيران.

استراتيجيات رئيسية لضمان معالجة المعادن الورقية عالية الجودة

1. الدقة الآلية وأجهزة CNC

- ·دور أجهزة CNC: ناقش كيف ثورة أجهزة التحكم الرقمي بواسطة الحاسوب (CNC) في معالجة المعادن الورقية بتقديم دقة غير مسبوقة. القطع بالليزر، التثقيب، الانحناء، والتقطيع يتم تحسينها جميعًا بواسطة أنظمة CNC، مما يضمن جودة واتساق الأجزاء.

- ·التقدم في التشغيل متعدد المحاور: أبرز كيف تحسن أجهزة CNC ذات المحاور الخمسة من دقة ومعقدة أجزاء المعادن الورقية، وتقلل من الأخطاء في عملية التصنيع وتقدم منتجات ذات جودة أعلى.

2. أنظمة السيطرة على الجودة المتكاملة

- ·مراقبة الجودة في الوقت الفعلي: شرح كيفية تسهيل التحكم في الجودة في الوقت الفعلي من خلال أنظمة الفحص الآلية التي تستخدم رؤية الآلة وخوارزميات الذكاء الاصطناعي لاكتشاف العيوب أثناء الإنتاج.

- ·الحساسات الذكية وشبكة الأشياء: عرض كيفية استخدام أجهزة إنترنت الأشياء (IoT) والحساسات الذكية لمراقبة أداء الآلات، وكشف التآكل، وإخطار المشغلين بالمشكلات المحتملة قبل أن تؤثر على جودة القطعة.

3. تحسين اختيار المواد وإدارتها

- ·تعقب المواد: مناقشة الأهمية المتزايدة لاستخدام المواد المعتمدة في عملية التصنيع وكيفية ضمان تعقب المواد لضمان استخدام المواد الخام عالية الجودة في إنتاج قطع المعادن المفلطحة.

- ·سبائك متقدمة وطلاء: الحديث عن استخدام السبائك المعدنية المتقدمة والطلاء (على سبيل المثال، الصلب المغلفن، الطلاء المسحوق) التي تحسن من متانة ووظائف قطع المعادن المفلطحة.

الابتكارات التقنية التي تدفع الجودة في معالجة المعادن المفلطحة

1. القطع بالليزر المتقدم

- ·ناقش دور ليزر الألياف وليزر CO2 في تحقيق قطع عالية الجودة مع تشوه حراري ضئيل ودقة حافة قصوى.

- ·فسر كيف يمكن لعملية القطع بالليزر أن تعمل مع مجموعة متنوعة من المواد، بما في ذلك الفولاذ المقاوم للصدأ، والألومنيوم، والنحاس، مما يضمن إنهاء نظيف وجودة عالية.

2. الروبوتات والتحكم الآلي

- ·أبرز كيف تساهم ذراعان روبوتية والمقصات اليدوية الآلية في تعزيز الدقة والسرعة في معالجة المعادن الصفيحية.

- ·اذكر كيف تحسن الروبوتات القابلية للتكرار والاتساق، مما يسمح للمصنعين بتحقيق تحملات أضيق بينما يزيدون من كفاءة الإنتاج العامة.

3. الطباعة ثلاثية الأبعاد في صناعة المعادن الصفيحية

- ·التصنيع الهجين: قدم الطباعة ثلاثية الأبعاد (التصنيع الإضافي) كتكنولوجيا مكملة لمعالجة المعادن الصفيحية التقليدية. تحدث عن استخدام الطباعة ثلاثية الأبعاد للمعادن في النماذج الأولية والإنتاج الضخم لتحقيق المواصفات الدقيقة ومعايير الجودة العالية.

4. المحاكاة والاختبار الافتراضي

- ·أنظمة CAD وCAM: التركيز على كيفية مساعدة أنظمة التصميم المساعد بالحاسوب (CAD) والتصنيع المساعد بالحاسوب (CAM) للمصنعين في محاكاة أجزاء المعادن قبل إنتاجها، مما يضمن اكتشاف أي عيوب في التصميم أو مشاكل في الجودة في مرحلة مبكرة.

- ·النمذجة الافتراضية: الإشارة إلى كيفية السماح للاختبارات الافتراضية بإجراء اختبارات الضغط الافتراضية وتقييم أداء المواد وتحليل الجودة قبل صنع الأجزاء فعليًا.

مستقبل معالجة المعادن عالية الجودة

- ·الصناعة 4.0 والمصانع الذكية: مناقشة كيفية استمرار تقنيات الصناعة 4.0 مثل الذكاء الاصطناعي، البيانات الكبيرة، والمصانع الذكية في دفع الحدود لتحسين كفاءة ومعايير جودة معالجة المعادن.

- ·تركيز الاستدامة: استكشاف كيف تؤثر جهود الاستدامة على معايير الجودة، من تقليل هدر المواد إلى تحسين استخدام الطاقة أثناء الإنتاج.