Сграда 49, индустриален парк Fumin, село Pinghu, област Longgang

Неделя Затворено

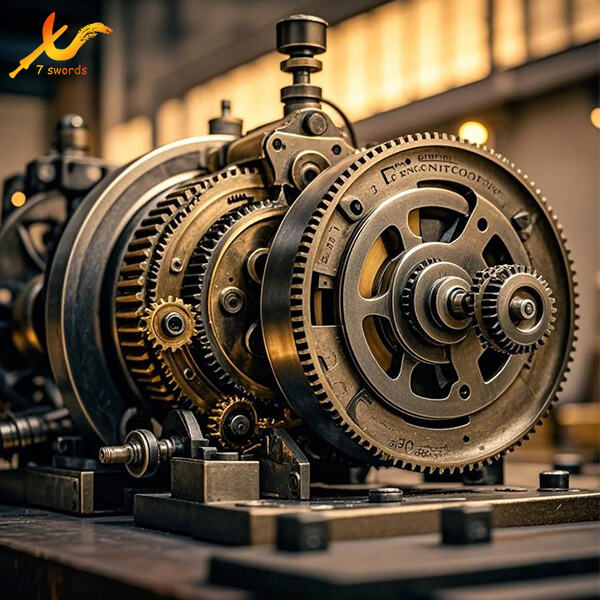

Аерокосмически прецизни части are specific types of wheels, having teeth and located within machines. They are crucial in transferring power from one part of the machine to the next. Internal gears are used in many different types of machines and each has its strengths and weaknesses. By unpacking how these gears function, you might be better able to use them, and care for them, appropriately.

Shifting power around through internal gears allows machines to function. They are made up of tightly interlocking teeth, much like puzzle pieces. When one gear begins to turn, it presses against the teeth of the other gear. This move also turns the second gear. The interaction between the gears helps transfer power throughout the machine to perform its function effectively and efficiently.

Palmer says one of the best things about internal gears is it can fit in small areas. That's great for tight spots, and makes them well-suited for small machines with all those parts crammed in.

They’re very efficient, meaning they don’t have much power loss moving energy from one part of the machine to another. This improves the efficiency of machines and saves energy.

They can also be tough to repair when they break. They are concealed within the machine, so they are not entirely easy to access for repairs, making maintenance somewhat more complicated.

One of the major differences between internal gears and other types of gears is the way they are internal to the machine itself. External gears are the ones outside, and internal gears are on the inside of the machine. This variation can adjust the required size of the machine while also adjusting the complexity involved in making repairs on the gears as needed.

Internal GEARS — if your machine runs on internal gears, you'll want to give them proper care so that your machine functions seamlessly for many more strokes. Here are some helpful tips:

We offer OEM and ODM services The minimum order amount is 1 unit Quotes are sent within three hours Sample production requires 1 to 3 days Bulk delivery can take 7 to Internal gears Our monthly production surpasses 300 000

We have a range of production machines, including 3-axis and 4-axis that can go up to 6-axis. We offer a variety of processing capabilities that include turning, milling, grinding, Internal gears and EDM and 3D Printing. We can work with a range of materials like copper, brass, aluminum and stainless steel, composites, plastics and crafting components that meet to any industrial requirement.

Our Internal gears engineering team is available 24/7, and ready to answer any questions you may have. They are highly skilled and have the experience to address your concerns. Custom parts with high precision tolerances: +/-0.01 mm, Special space: +/-0.005 mm.

Internal gears have ISO9001 certificate, ISO14001, ISO45001, medical ISO13485, aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. Всички права запазени — Политика за Поверителност - Блог