Разбиране на прецизната обработка на листово метал: Поставяне на висококачествена броня на modenата индустрия

Технологичен напредък

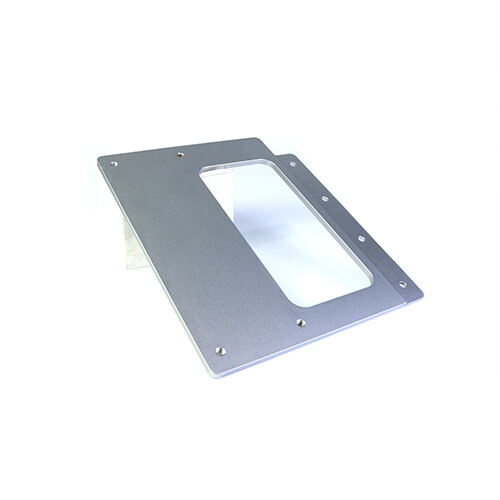

В днешното бързо развиващо се индустриално поле прецизната обработка на листова метална продукция става основата за качеството в modenата индустрия, благодаря на своите впечатляващи технологични постижения. Тя е като точен занаятчик, който се опира на modenо оборудване, изискано умение и строг контрол на качеството, за да наделява различни индустриални продукти с прочни и изящни корпуси, както и с високопrecизни вътрешни конструктивни компоненти. От шасито на автомобилното производство до прецизните корпуси на електронните устройства, от ключовите компоненти в аерокосмическата индустрия до високопrecизните конструктивни части в медицинското оборудване, прецизната обработка на листова метална продукция е навсякъде, а всеки процес демонстрира иновации и мудрост. Чрез непрекъснатото подобряване на техниките за рязане, прецизните процеси на извиване и достоверните методи на сваряване, тя гарантира размерната точност, формовната стабилност и конструктивната силност на продукта, ефективно повишавайки неговите характеристики и надеждност. Това технологично напредване не само отговаря на все по-строгите изисквания на modenата индустрия за качеството на продуктите, но и осигурява солидна подкрепа за развитието на различните индустрии, насърчавайки стабилното продвижение на modenата индустрия по пътя на висококачественото развитие и постоянно създавайки нови блестящи постижения.

Отлични предимства

Точната обработка на листова метала е доказала много значителни предимства в modenата индустрия, като заложи твърда основа за гарантиране на високото качество. Нейната висока гъвкавост и персонализация позволяват да се създават точно листови метални части различни по формата и размерите, според специфичните нужди на различните индустрии и продукти. Дали става дума за сложни геометрични конструкции или строги толеранси, тя може лесно да се справи с тях, отговаряйки на разнообразните и персонални производствени нужди на modenата индустрия. Едновременно, точната обработка на листова метала използва напреднали технологии и оборудване, което гарантира висока прецизност и стабилност на качеството на продуктите. През процеса на обработката степента на употребление на материалите е изключително висока, което ефективно намалява производствените разходи, подобрява производствената ефективност и принася значителни икономически предимства за предприятията. Повече от това, продуктите след обработката на листова метала имат добри прочност и жесточинство и могат да поддържат стабилна производителност в различни тежки условия, осигурявайки силна гаранция за продължителното и надеждно функциониране на modenите индустриални машини. Тези предимства правят точната обработка на листова метала много ценена в много индустриални области и незаменима сила за насърчаване на висококачественото развитие на modenата индустрия.

Запитване и работна стабилност

При бързото развитие на modenата индустрия, прецизната метална обработка на листовасти осигурява висококачествено задоволство на производствените дейности в различни области, благодарение на точното си съвпадение с индустриалните нужди. С бързото развитие на технологиите, индустриалните продукти все повече се насочват към висококласни, интелигентни и прецизни, а изискванията за прецизност, качество и стабилност на компонентите стават все по-строги. Прецизната метална обработка на листовасти, със своята напреднала процесна технология и стриктна система за контрол на качеството, може да отговори на тези сложни и разнообразни нужди. Дали е двойното търсене на лековесни и високопрочни авиационни компоненти в аерокосмическата индустрия, или високопрецизните размерни изисквания за прецизни огледали в електронната и комуникационната индустрия, прецизната метална обработка на листовасти може да се справи с тях без проблеми.

Що се отнася до работната стабилност, прецизният метален обработване на листовасти извършва отлично. То гарантира, че всяка листова метална част отговаря на последователни висококачествени стандарти, оптимизирайки производствените процеси, използвайки високопрецизно оборудване и строги процеси за качествена проверка. От избора на суровините до доставката на готовите продукти, всеки процес е внимателно планиран и строго изпълняван, ефективно намалявайки грешките и неопределностите в производствения процес. Тази стабилна производствена способност позволява на прецизния метален обработване на листови да завършва доставката навреме, с високо качество и количество, дори при голям мащаб на производството, предлагайки твърда подкрепа за продължителното и стабилно функциониране на modenите индустриални линии за производство. Дали се занимава със спешни поръчки или дългосрочни производствени сътрудничества, прецизният метален обработване на листови е заслужил доверието на клиентите и пазарното признание със своята надеждна работна стабилност, ставайки незаменим и важен поддръжкин звено в modenата индустрия.

Конкурентна заплата и beneficii

На сцената на modenата индустрия, прецизният метален обработващ бизнес разбира, че таланта е ключов елемент за предоставяне на висококачествено задоволство. За да привлекат и задържат отлични таланти, бизнесът активно насърчава конкурентна система за заплати и beneficii. Чрез предлагане на заплати и beneficii по-високи от среднорыночните, пъленото признаване и отразяване на професионалните умения и трудовият напредък на служителите ни мотивират да стремят към превъзходство във всяка част от прецизния метален обработващ процес. Не само това, богатството и разнообразието на социалните програми са станали една от основните точки на бизнеса – от всестранно медицинско осигуряване и пенсионно осигуряване за защита на живота на служителите, до платена годишна почивка, празнични бонуси и др., които позволяват на служителите да се наслаждават на прекрасното на живота и да чувстват грижата и топлината на предприятието през свободното си време. Тази привлекателна система за заплати и beneficii не само събира голямо число висококачествени и технически умелостни професионалисти за прецизния метален обработващ бизнес, но и залага прочна основа за бизнеса да продължава стабилно да предоставя висококачествено задоволство на modenата индустрия, позволявайки на прецизния метален обработващ бизнес да се изразличава в жестоката пазарна конкуренция с предимства на таланта и постоянно да насърчава modenата индустрия да се движи към стадии на по-високо качество развитие.

Резюме

Точната обработка на листова метална продукция играе ключова роля в съвременната индустриална система и е основната сила, която осигурява високото качество. Тя преминава през всеки етап от избора на суровините до доставката на готовите продукти, ползвайки moden технологии, изискано занаятство и строг контрол върху качеството. Чрез висока гъвкавост и персонализация, тя отговаря на различните нужди на различните индустрийни области, създавайки прочни, точни и естетично привлекателни корпуси и вътрешни конструктивни компоненти за различно висококачествено оборудване и прецизни продукти. Нейното отлична производителност относно работната стабилност гарантира ефективността и надеждността на масовото производство, предлагайки силна подкрепа за непрекъснатото функциониране на съвременните индустриални линии за производство. Едновременно, индустрията активно насърчава конкурентна системата за заплати и социални блага, привличайки и задържайки голям брой висококвалифицирани таланти, които дават постоянен поток на сили за технологични иновации и подобряване на качеството. Точната обработка на листова метална продукция не само е твърда гаранция за висококачественото развитие на съвременната индустрия, но и мощен двигател за продължаващото напредване на цялата индустриална област. Тя ще продължи да играе незаменима ключова роля в бъдещия индустриален пейзаж, водейки индустрията към по-високи нива на качество и по-широко пространство за развитие.