How to Use CNC Machining to Achieve High-Precision Gear Machining

CNC (Computer Numerical Control) machining has revolutionized the manufacturing industry, particularly in the production of high-precision gears. This advanced technology offers unparalleled accuracy, efficiency, and reliability, making it an essential tool for engineers and manufacturers. In this article, we will explore the key steps and best practices for using CNC machining to achieve high-precision gear machining.

Understanding the Importance of High-Precision Gears

Gears are critical components in various mechanical systems, including automotive, aerospace, and industrial applications. The precision of these gears directly affects the performance, efficiency, and longevity of the entire system. High-precision gears ensure smooth operation, reduce noise, and minimize wear and tear.

The Role of CNC Machining in Gear Production

CNC machining offers several advantages over traditional manufacturing methods when it comes to producing high-precision gears:

Accuracy and Consistency: CNC machines can achieve extremely high levels of accuracy, often within microns. This consistency is crucial for gears, where even slight variations can lead to significant performance issues.

Complex Geometries: CNC machining can handle complex geometries and intricate designs that are difficult or impossible to achieve with manual methods. This capability is particularly important for specialized gears used in high-performance applications.

Material Flexibility: CNC machines can work with a wide range of materials, including metals, plastics, and composites. This flexibility allows manufacturers to choose the most suitable material for their specific needs.

Efficiency and Speed: CNC machining is significantly faster than manual methods, reducing production time and costs. This efficiency is particularly beneficial for large-scale production runs.

Step-by-Step Guide to Achieving High-Precision Gear Machining with CNC

Step 1: Design and Simulation

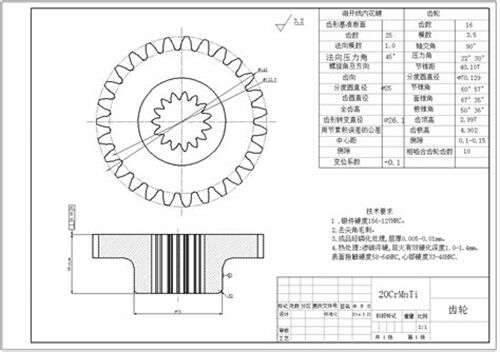

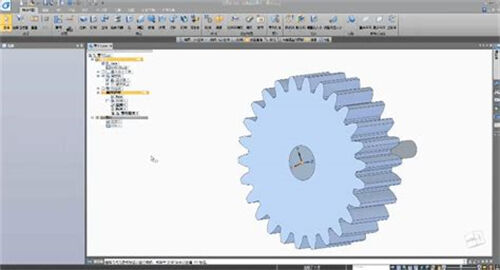

Before starting the machining process, it is essential to create a detailed design and perform simulations to ensure the gear meets all required specifications. CAD (Computer-Aided Design) software can be used to create precise models and analyze potential issues before production begins.

Step 2: Material Selection

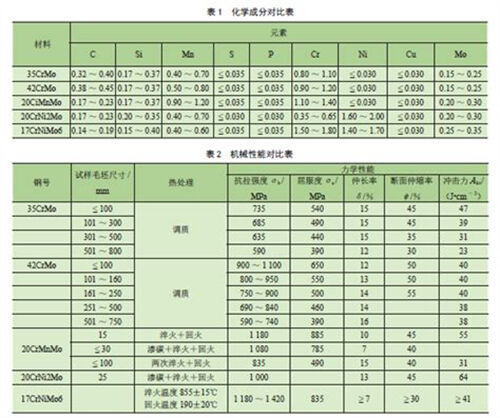

Choose the appropriate material based on the application requirements. Common materials for gear production include steel, aluminum, and titanium. Each material has its own properties and advantages, so careful selection is crucial.

Step 3: Tooling and Setup

Select the appropriate cutting tools and set up the CNC machine according to the gear design. This step involves selecting the right cutting speed, feed rate, and depth of cut to ensure optimal performance and tool life.

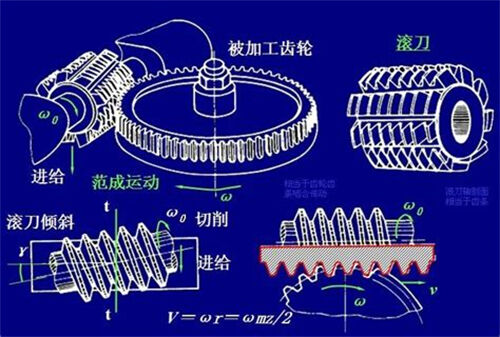

Step 4: Machining Process

Execute the machining process using the CNC machine. This may involve multiple operations such as milling, drilling, and grinding to achieve the desired shape and surface finish.

Step 5: Inspection and Quality Control

After machining, inspect the gears using advanced measurement techniques such as coordinate measuring machines (CMMs) or laser scanning. This step ensures that the gears meet all specifications and are ready for assembly or further processing.

Step 6: Post-Processing

Perform any necessary post-processing steps such as heat treatment, surface finishing, or coating to enhance the gear's performance and durability.

Real-World Applications and Case Studies

One notable example is the work of MEC CNC's Anthony Usher, who has successfully guided customers through the process of creating simple CNC machines for those without prior computer experience . This approach has filled a significant gap in the market, making high-precision gear machining accessible to a broader range of manufacturers.

CNC machining is a powerful tool for achieving high-precision gear machining. By understanding the importance of precision, leveraging the advantages of CNC technology, and following a structured approach to design, material selection, tooling, machining, inspection, and post-processing, manufacturers can produce high-quality gears that meet the demands of various industries. Whether you are a seasoned engineer or just starting out, mastering CNC machining for gear production can open up new opportunities for innovation and efficiency.