Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Diumenge Tancat

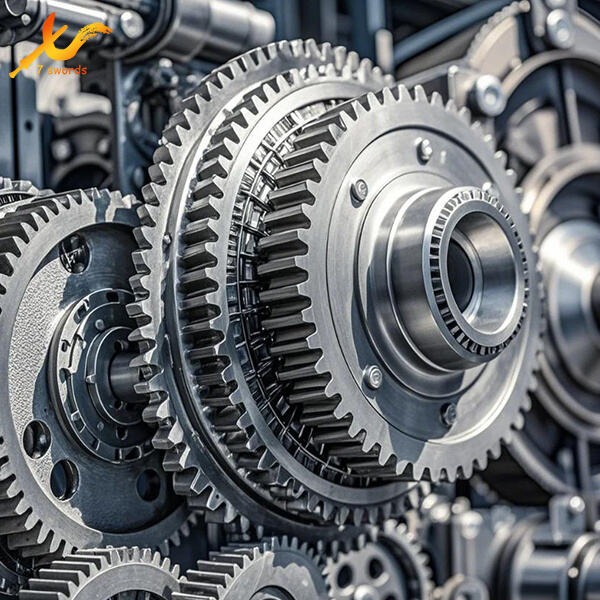

Els engranatges són components crucials de molts tipus de maquinari. Això és una part important per permetre la feina cooperativa entre màquines. Els engranatges industrials, variants úniques d'un engranatge, es fabriquen especialment per aplicacions en una fàbrica i plantes de fabricació. Aquests engranatges s'utilitzen en diverses màquines, des d'una mida de cotxe de juguete fins a equips immensos d'una fàbrica. Conèixer els engranatges industrials és essencial per a qualsevol treballador d'una fàbrica o persona familiaritzada amb el maquinari.

Els engranatges són de diverses formes i mides. Hi ha diversos tipus d'engranatges que es fan servir per la majoria d'aplicacions industrials, com ara engrenatges dretors, engrenatges helicoidals, engrenatges cònics i engrenatges de vermell. Cada un d'aquests tipus d'engranatge té les seves pròpies avantatges i desavantatges. Realitzen diferents tasques segons la seva necessitat. Conèixer què fa cada tipus d'engranatge és molt important ja que voldràs triar el correcte per al treball o tasca en qüestió.

L'equipament adequat per a una fàbrica és crucial per mantenir totbé en camí, i això significa que el primer pas que heu de donar és escollir els materials adequats. És important tenir en compte moltes coses quan trieu un engranatge. Heu de prendre en consideració què tan gran i poderosa és la màquina que esteu utilitzant, què tan ràpida ha de funcionar, i què tant haurà de suportar la màquina amb l'ús prolongat.

El manteniment correcte dels engranatges és essencial per mantenir els vostres engranatges funcionant bé i durant molt de temps. Això significa fer manteniment regular i mantenir-los ben olivats o lubrificats. En part, l'oli ofereix protecció contra la ferrugem i altres danys als engranatges. Això també disminueix la fricció — la resistència creada quan les parts es mouen entre elles. Reduir la fricció ajuda a prevenir l'us i desgast dels engranatges amb el temps.

Els engranatges han d'estar també ben olivats perquè absorbene xocs i es produeix soroll quan els dents giren. Això és especialment crucial en el que fa a la manteniment regular, que ens permet detectar problemes potencials abans que es converteixin en problemes més grans. Això ajuda a solucionar problemes menors abans que es convirtin en problemes majors que podrien requerir reparacions costoses i posar les màquines fora de servei.

Swords Precision és una de les pioneers d'aquestes noves innovacions. Es basen en programari d'ús avançat per dissenyar engranatges que funcionen amb precisió i que es poden produir de manera eficient. Com a exemple, l'equip tècnic utilitza la seva pròpia tecnologia únic que neutralitza el soroll i les vibrations que surten dels engranatges giratoris i sistemes motors, però simultàniament n'incrementa la funció. Aquesta nova tecnologia ja s'ha aplicat amb èxit en una àmplia gamma d'aplicacions industrials, des de la robòtica fins als sistemes d'automatització.

Aquest equipament s'utilitza també en l'automòbil, aeronàutica, mineria, petroli i gas, producció d'aliments, i moltes altres indústries. En el món dels vehicles, els engranatges es fan servir per transferir potència en els motors, caixes de canvi i diferencials per moure el vehicle endavant des del motor fins als rodes del vehicle. Per exemple, en la mineria i la pedrera, els engranatges són essencials per als sistemes de transport que porten materials i per als treballadors que trencen roques i minerals.

El nostre equip de producció està format per: màquines de 3 eixos (Engrenatges industrials), 5 eixos i també de 6 eixos. Les nostres capacitats de processament inclouen tornat, fresat, perforat,ritzat, EDM, Impressió 3D i més. Treballem amb molts materials diferents, incloent alumini, bronze i cupro nickel acer inoxidable plàstics, compositius i.

Tenim el certificat ISO9001, ISO14001, ISO45001, mèdic ISO13485, aviador AS9100, Engrenatges Industrial, podem produir parts mecàniques, parts d'automòbil, parts electròniques, parts aeroespacials, parts de dispositius mèdics, parts d'equipaments de comunicació, parts d'energia nova, i parts per a la construcció i productes domèstics.

Els serveis OEM i ODM estan disponibles. La quantitat mínima per als pedidos és 1 peça. Es donen pressupostos dins dels Engrenatges Industrial. La producció de mostres triga entre 1 i 3 dies laborables. El temps de llavor per als comandaments en gros és entre 7 i 14 dies laborables. La nostra producció mensual supera els 300.000.

Tenen una ampla expertesa i experiència per resoldre totes les teves preocupaçions. Són molt qualificats i tenen els Engrenatges Industrial per resoldre les teves preocupaçons. Parts personalitzades amb toleràncies de precisió alta: + /-0.01 mm, Espai especial: + /-0.005 mm.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog