Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Diumenge Tancat

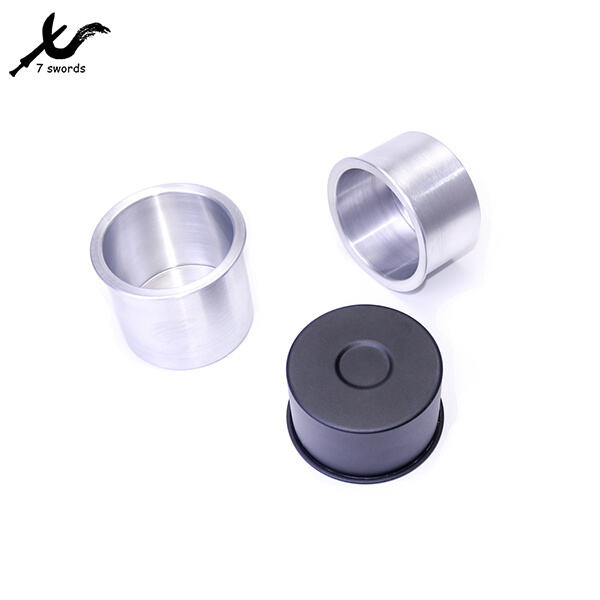

Per tant, continua llegint per descobrir més sobre el procés d'estampat metàl·lic—què és i què fa! Peça metàl·lica CNC es refereix a un mitjà específic per a formar fulls de metalls. Aquest és el mode en què els fulls es tallen i formen mitjançant eines i màquines especials per aconseguir el que les persones volen. ET OFERIM SELLS METÀL·LIQUES PER ACONSEGUIR UNA ALTA QUALITAT: Des de Swords Precision, la nostra gamma d'experts especialistes en produir productes de sella metàl·lica d'alta qualitat que són apreciats pels nostres clients i versatils per al teu ús.

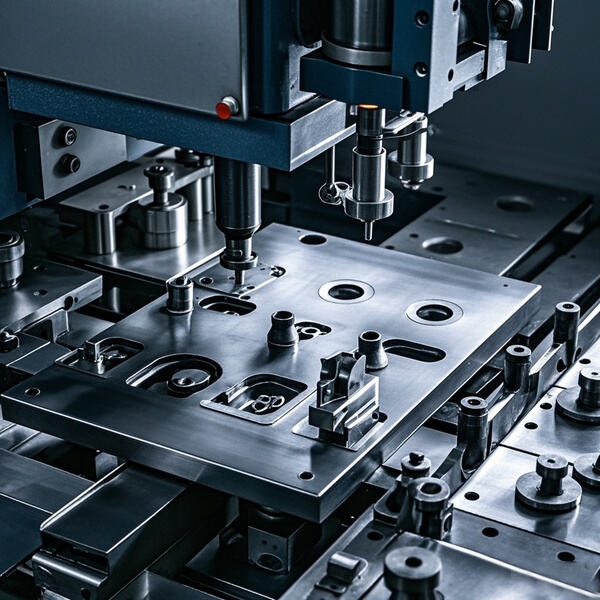

El procés d'estampació metàl·lica comença amb un disseny que es crea utilitzant o bé paper o un programa d'ordinador. Una màquina que ajuda en aquest pas s'utilitza per transferir aquest disseny sobre una fulla de metal. Un cop el disseny està a la fulla de metal, es talla en una forma específica amb una eina coneguda com a mat. Al igual que un mold actua com a mat per tallar un disseny perfectament. Després d'això, el metal s'ajusta a la forma correcta i s'forma en una premsa d'estampació. L'ús d'aquesta premsa permet obtenir el disseny final que desitgem. Tot això resulta en una peça metàl·lica neta i precisa que també es pot utilitzar per a diverses aplicacions, des de la creació de parts de màquina funcionals fins a joieria impressionant.

Fabricant de parts metàl·liques personalitzades és més que formar objectes; realment és un gran art en si mateix. A Swords Precision, hem dominat la capacitat de crear dissenys bels i complexos en metall utilitzant tècniques de formació. Després d'una dècada o fins i tot més practicant abans de graduarse en enginyeria civil, podem crear dissenys abstractes que són tan estètics com la seva funcionalitat.

La tecnologia d'estampat metàl·lic permet dissenys d'aquest estil amb una gamma de textures i articles. Afegeix un to extra al disseny i el fa més destacable, atrapant l'atenció de tothom que el miri. La llista és infinita, des d'una bonica peça de joieria fins a una peça essencial per a un vehicle, amb moltes més aplicacions d'aquest procés disponibles. I com en una dimensió superior, elements únics i especials per a tu també es poden fer.

La màquina que utilitzem estampa literalment les peces de metall en producció massiva. Això millora significativament la nostra productivitat mentre reduïm el temps de desenvolupament del producte. També tenim sensors únics als nostres prenses d'estampat que identifiquen si hi ha algun problema amb el metall mentre s'estampa. Això ens permet crear només peces excepcionals que els nostres consumidors desitgen i mereixen.

L'estampat metàl·lic serveix molt bé a l'indústria automotiva a través de la fabricació de parts com suports, tenacilles i moltes altres parts. L'estampat metàl·lic és un procés de fabricació que està ben adaptat per satisfer aquests requisits ja que desafia la precisió en la forma i l'exactitud de les parts metàl·liques. Assegura que les peces es disposin sense solcades i funcionin correctament. Aquest procés inclou la formació d'una varietat de metalls que formen parts essencials per a l'indústria aerospacial, com avions i altres màquines voladores.

L'estampat metàl·lic també és una gran manera d'aprendre una nova habilitat i començar al món fascinant del treball del metall! L'estampat metàl·lic és un artesanat que les persones poden adquirir amb algunes pràctiques i paciència, i produir creacions belles i funcionals. No només pots gaudir del procés, sinó que també pots crear coses útils i significatives.

Tenim una sèrie de màquines de producció, incloent-hi eixos 3 i 4 que poden arribar fins a 6 eixos. Oferem una varietat de capacitats de processament que inclouen tornadura, fresatge, llafador, estampació metàl·lica i EDM i Impressió 3D. Podem treballar amb una gamma de materials com el cuprat, la gerra, l'alumini i l'acer inoxidable, composites, plàstics i fabricant components que compleixen qualsevol requisit industrial.

Oferem serveis OEM i ODM. La quantitat mínima d'enviament és d'estampació metàl·lica. Podem proporcionar pressupostos en un termini de 3 hores. La producció de mostres triga entre 1 i 3 dies laborables. L'enviament massiu triga entre 7 i 14 dies. La nostra capacitat de producció mensual supera els 300.000 peces

El nostre equip d'enginyers està sempre disponible, preparat per respondre ràpidament a les vostres consultes sobre estampació metàl·lica. Són altament qualificats i tenen el coneixement per resoldre les vostres preoccupacions. Parts personalitzades amb toleràncies de precisió altes: +/-0,01 mm, Àrea especial: +/-0,005 mm.

Tenim el certificat ISO9001, ISO14001, ISO45001, mèdic ISO13485, aviador estampació metàl·lica, Automòbil IATF16949, podem produir parts mecàniques, parts d'automòbil, parts electròniques, parts d'aeronàutica, parts d'aparells mèdics, parts d'equipaments de comunicació, parts d'energia nova, parts de construcció i productes domèstics.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog