Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

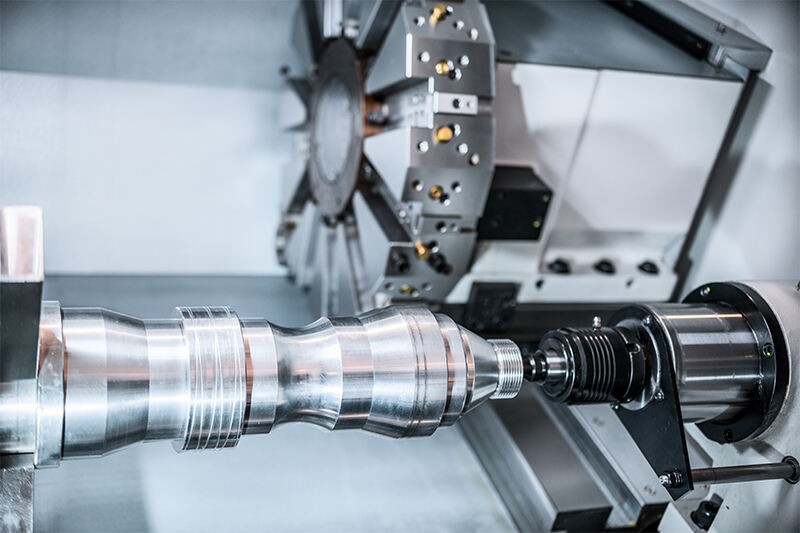

Discover precision and reliability with our CNC machining services for aluminum. At 7 Swords, we specialize in delivering high-quality, custom aluminum parts crafted to your exact specifications. With a commitment to meeting

Why Choose CNC Machining for Aluminum?

Aluminum is renowned for its versatility, strength-to-weight ratio, and corrosion resistance, making it a preferred material across various industries—from aerospace to automotive and beyond. CNC (Computer Numerical Control) machining, with its ability to achieve intricate designs and tight tolerances, is the ideal method for shaping aluminum into precise components.

Our Advanced CNC Machining Capabilities

At 7 Swords, we leverage state-of-the-art CNC machines equipped with the latest software and tools. This allows us to execute complex machining operations with efficiency and accuracy. Whether you require prototypes or large-scale production runs, our capabilities ensure consistent quality and adherence to your specifications.

| Parameter | Description |

| Material | Aluminum (Alloys: 6061, 7075, etc.) |

| Tooling | Carbide or High-Speed Steel |

| Cutting Speed (SFM) | 600 - 2500 SFM (Depends on alloy and tooling) |

| Spindle Speed (RPM) | 2000 - 12000 RPM (Varies with cutter diameter and material) |

| Feed Rate (IPM) | 10 - 200 IPM (Depends on cutter geometry and material) |

| Depth of Cut (DOC) | 0.1 - 0.5 inches (Varies based on tool diameter and rigidity) |

| Coolant | Mist, Flood, or Dry (Application-specific) |

| Surface Finish | Ra 0.4 - 16 in (Depends on tooling and machining strategy) |

| Tolerances | +/- 0.01 - 0.005 inches (Depends on part complexity) |

Key Considerations for CNC Machining Aluminum

1.Material Specifics: Choose the appropriate aluminum alloy based on mechanical properties and application requirements.

2.Tool Selection: Optimize tooling for aluminum machining to maximize efficiency and tool life.

3.Optimal Parameters: Adjust cutting speed, feed rate, and depth of cut to achieve desired part quality and productivity.

4.Coolant Application: Implement suitable coolant strategies to enhance tool life and manage heat generation.

5.Quality Assurance: Maintain tight tolerances and surface finishes through effective machining practices and inspection protocols.

Benefits of CNC Machining Aluminum with Us

1.Precision Engineering: Our CNC machines deliver micron-level precision, ensuring each aluminum part meets exacting standards.

2.Cost-Effectiveness: Through efficient processes and minimized material waste, we offer competitive pricing without compromising on quality.

3.Customization Options: From intricate geometries to specific surface finishes, we accommodate diverse customer requirements with flexibility.

4.Fast Turnaround: We understand the importance of timelines. Our streamlined workflow and responsive team ensure prompt delivery of your CNC-machined aluminum parts.

Industries We Serve

Our expertise in CNC machining aluminum caters to a wide range of industries, including:

1.Aerospace: Components requiring lightweight strength and durability.

2.Automotive: Precise parts for engines, chassis, and interiors.

3.Electronics: Heat sinks, enclosures, and connectors that demand thermal conductivity and electrical insulation.

4.Medical: Instruments and devices that prioritize biocompatibility and precision.

Why Partner with 7 Swords?

Choosing 7 Swords for CNC machining aluminum means partnering with a dedicated team committed to excellence. With years of experience and a proven track record, we stand ready to meet your machining needs, no matter how intricate or demanding.

FAQ

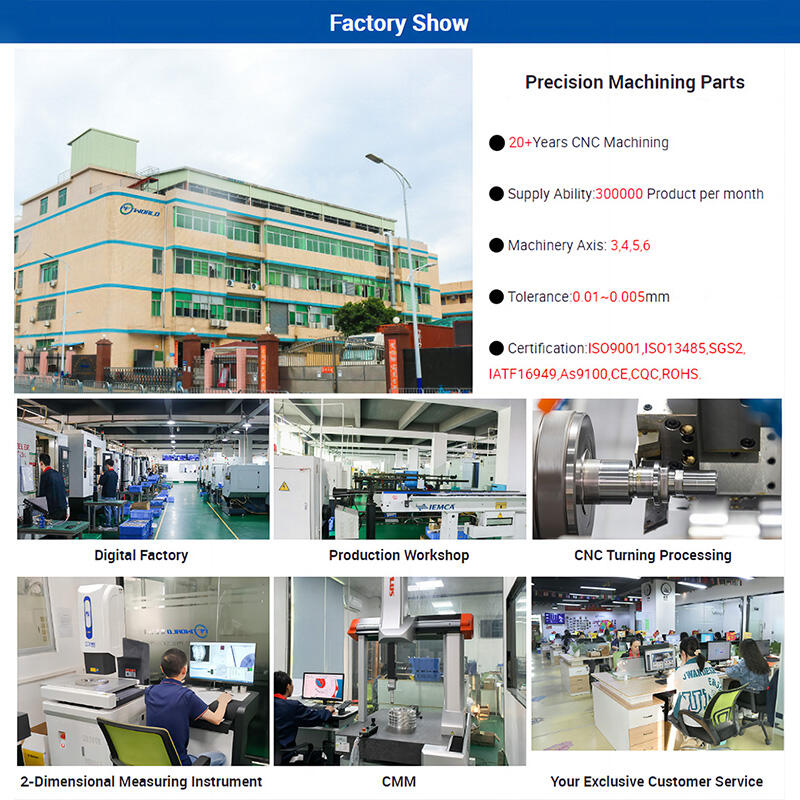

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog