Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Discover precision-engineered custom gears tailored to meet your specific industrial needs at 7 Swords. Our comprehensive gear customization services ensure optimal performance and durability, crafted with advanced CNC technology for accuracy.Trust 7 Swords for superior custom gears that enhance efficiency and performance in your operations

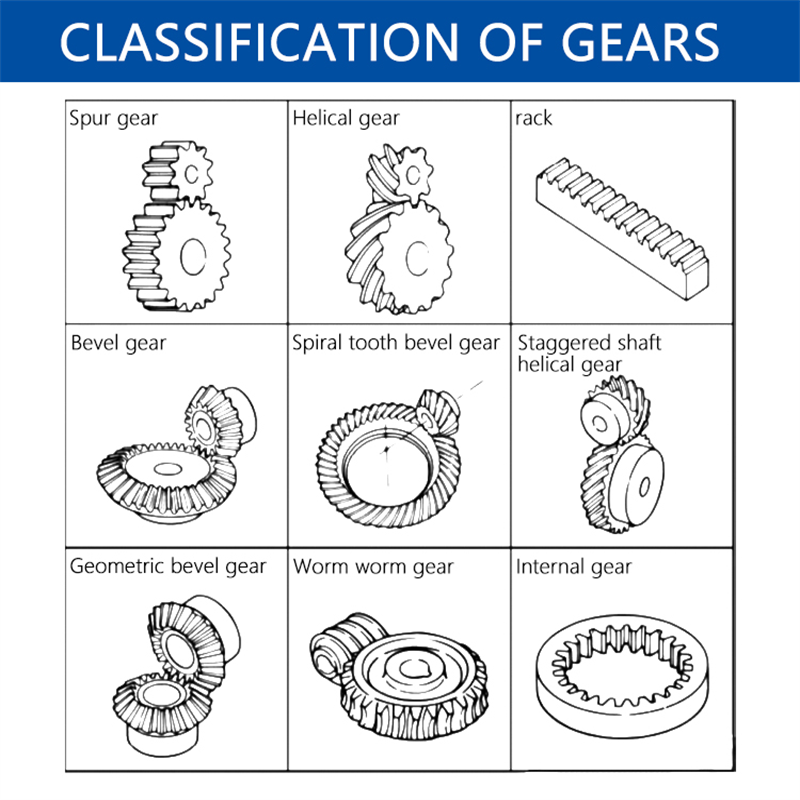

Custom Gears: Precision Solutions for Industry Needs

In the world of manufacturing and industrial operations, precision and reliability are paramount. Custom gears play a crucial role in ensuring seamless functionality across various applications, from automotive and aerospace to robotics and heavy machinery. At 7 Swords, we specialize in designing and manufacturing custom gears that meet the unique requirements of our clients.

Tailored Solutions

No two applications are exactly alike, which is why off-the-shelf gears often fall short. Custom gears offer tailored solutions that precisely match specific operational demands. Whether it’s a specific material requirement, unique dimensions, or specialized performance characteristics, our team of engineers and technicians collaborates closely with clients to design gears that fit perfectly into their systems.

Advanced Manufacturing Techniques

Utilizing state-of-the-art CNC machining technology and advanced gear design software, we ensure the highest levels of accuracy and efficiency in gear production. This technology allows us to achieve tight tolerances and intricate geometries, enhancing the performance and longevity of our custom gears.

Wide Range of Applications

From small-scale precision instruments to large-scale industrial machinery, our custom gears find applications across diverse industries:

1.Automotive: Precision gears for transmissions, differential systems, and steering mechanisms.

2.Aerospace: Lightweight, high-strength gears for aircraft engines and landing gear systems.

3.Robotics: Compact and efficient gears for robotic arms, joints, and mobility systems.

4.Heavy Machinery: Robust gears for mining equipment, construction machinery, and agricultural vehicles.

Quality Assurance

Quality is at the core of everything we do. Each custom gear undergoes rigorous testing and inspection to ensure it meets our stringent quality standards and exceeds customer expectations. We adhere to industry best practices and standards to deliver gears that perform reliably in demanding environments.

FAQ

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog