Luftfart

Inden for luftfart er hvert flyvepass en ekstrem test af teknologi og håndværk. Maskinbearbejdnings teknologi, som kernen i luftfartens produktion, bærer den store ansvar for flyets ydeevne og sikkerhed. Som et præcisionsproduktbearbejdningsselskab holder vi os foran i luft- og rumfartssektoren, og vi er certificeret til AS9100D. I processen spiller maskinbearbejdnings teknologi en afgørende rolle.

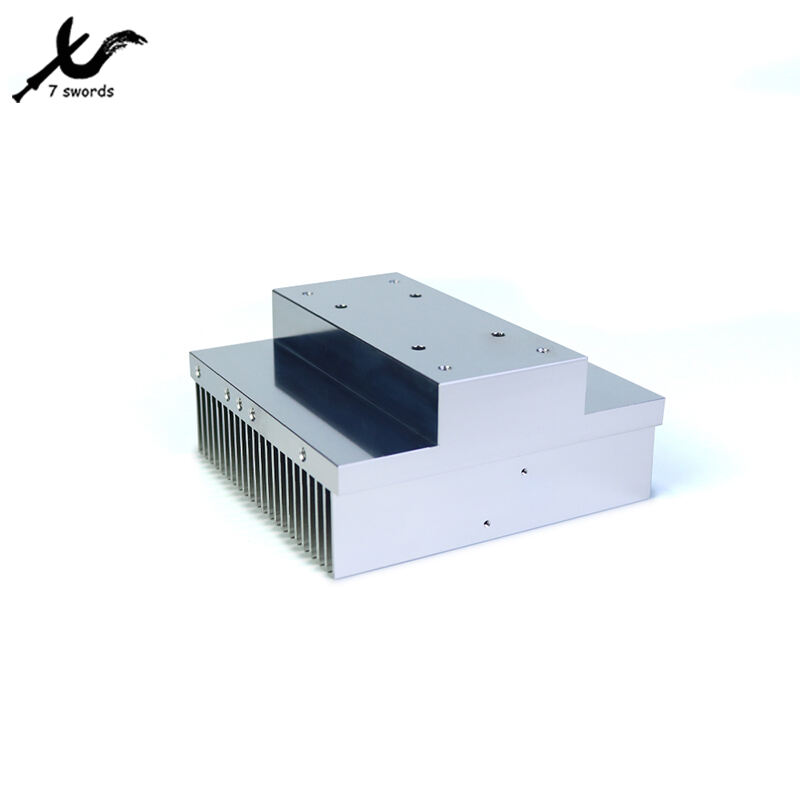

1. Bearbejdning af lette materialer

Luftfartsmaterialer skal være letvejende, højstærke og have god stivhed for at forbedre ydeevne og manøvrabilitet af fly; de skal kunne modstå høje driftstemperaturer og have fremragende korrosionsresistens, herunder spændingskorrosion og korrosionsutrastning. Givet karakteristikkerne for materialerne i luftfartsmaterialesektoren, leverer vi de højeste kvalitets luftfartsmaterialer såsom titanlegemer for at opfylde de forskellige krav, der stilles inden for dette felt. Behandlingen af letvejrende materialer såsom titanlegemer og højstærke aluminiumlegemer bruger specielle bearbejdningsteknikker såsom elektrokemisk behandling for at reducere varmevirkninger og deformation under materialefjerne.

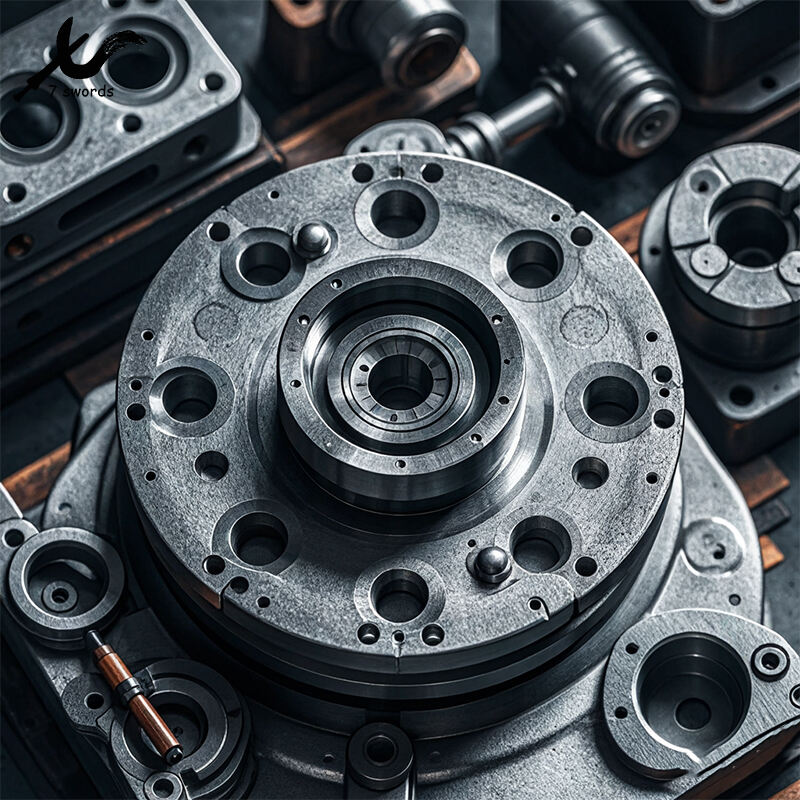

2.Behandling af komplekse strukturelle komponenter

Luftfartskomponenter har en række produkter med komplekse design, hvilket kræver højpræcise bearbejdnings teknologier; på grund af de særlige krav til anvendelsesmiljøet og ydeevne er luftfartskomponenter normalt meget tilpassede. For komplekse strukturelle komponenter, såsom flyvinge bjælker, landingsgear osv., bruges avancerede CNC-skærningscentre til fræsning, bore og tråde, således at flere bearbejdningstrin kan udføres i én fastgørelse. Vores fremragende ingeniørhold kan håndtere forskellige komplekse design og problemer gennem deres års arbejdsoplevelse og skarpt dømme.

3.Nøjagtighedspartsproduktion

Luftfartskomponenter skal have høj præcision og høj stivhed for at sikre stabiliet og flyveydelsen af flystrukturen; luftfartskomponenter bruger ofte svære-at-behandle materialer såsom titanier, højtemperaturslegeringer og sammensatte materialer, hvilket stiller højere krav til bearbejdnings teknologien; luft- og rumfartindustrien kræver, at størrelsen, tolerance og ydelse af hver enkelt komponent når de strengeste og højeste niveauer for at sikre, at komponenterne ikke fejler under flyvning. Det behandles ved hjælp af højpræcise 5-akse CNC-maskiner for at sikre geometrisk præcision og overfladeafslutning af komponenterne.