Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Søndag Lukket

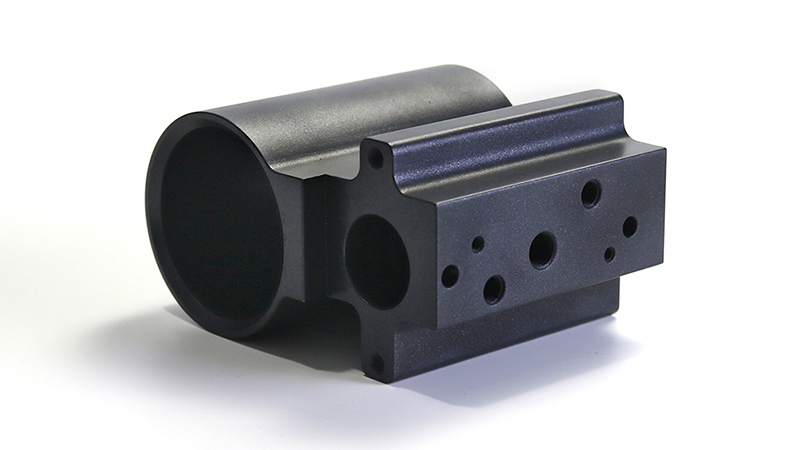

Edelstål metalcastingservices er processen med at fremstille dele og komponenter ved at hylde smeltet edelstål i en form og lade den solidificere. Denne metode bruges vidt om i industrier, der kræver korrosionsbeständighed, holdbarhed og dele med høj hårdfavn.

Fordele ved edelstålformtegn:

Designflexibilitet: Komponenter og sammensætninger med komplekse geometrier kan designes og produceres.

Materialegenskaber: Edelstål har fremragende korrosionsmodstand, styrke og holdbarhed.

Produktion i store mængder er økonomisk: Formtegning er en mere økonomisk produktionsmetode end andre fremstillingsmetoder, hvis mellem- eller store mængder af komponenter skal produceres.

Anvendelser:

Edelstålformtegn bruges i en række industrier, herunder:

Automobil: motorkomponenter, udstødningssystemer.

Luftfart: turbineblader, strukturelle komponenter.

Medicinsk: kirurgiske instrumenter, indplantater.

Energi: olie- og gasudstyr, turbinekomponenter.

Industrielt udstyr: ventilering, pumper, fittinger.

Ved valg af en stålstøbningstjenesteleverandør, overvej:

Erfaring og rygte: Søg efter en leverandør med en beviset track record inden for produktion af stålstøbninger.

Kvalitetssikring: Sørg for, at der er strenge kvalitetskontroller i virksomheden.

Evne: Spørg efter prøver for at verificere, at leverandøren kan håndtere størrelsen, kompleksiteten og mængden af din delprojekt.

Omkostninger og leveringstid: Få tilbud og vurder leverandørens priskonkurrenceevne og evne til at opfylde frister.

Ved at vælge en pålidelig stålmassivstøbningstjenesteleverandør som os, kan du være sikker på, at de dele eller sammensætninger, der produceres, er af høj kvalitet og vil opfylde dine krav til materials holdbarhed, ydelse og pålidelighed.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Fortrolighedspolitik—Blog