Marine

Die zentrale Rolle der Fertigungstechnologie in der Schifffahrt

Einleitung:

Die Schifffahrtsindustrie operiert in einer einzigartigen und anspruchsvollen Umgebung, weshalb Teile mit außergewöhnlichen Leistungsmerkmalen benötigt werden. Der Herstellungsprozess dieser Teile ist mit Herausforderungen behaftet, die herkömmliche Methoden nur schwer meistern können. Die Fertigungstechnologie hat in diesem Sektor an Bedeutung gewonnen und spielt eine entscheidende Rolle, wie die folgenden Fallstudien zeigen.

Laser-Schichttechnologie im Schiffsbau:

Im Schiffsbau sind Probleme wie Korrosion und Verschleiß alltäglich, und herkömmliche Reparaturmethoden sind nicht immer effektiv. Die Laser-Schichttechnologie hat sich als leistungsstarke Lösung zur Reparatur kritischer Schiffskomponenten etabliert. Ihre Vorteile umfassen eine minimale Wärmebeeinflussungszone, eine starke metallurgische Verbindung zwischen der Schicht und dem Basismaterial sowie eine feinkörnige, dichte Struktur, die die Haltbarkeit erhöht.

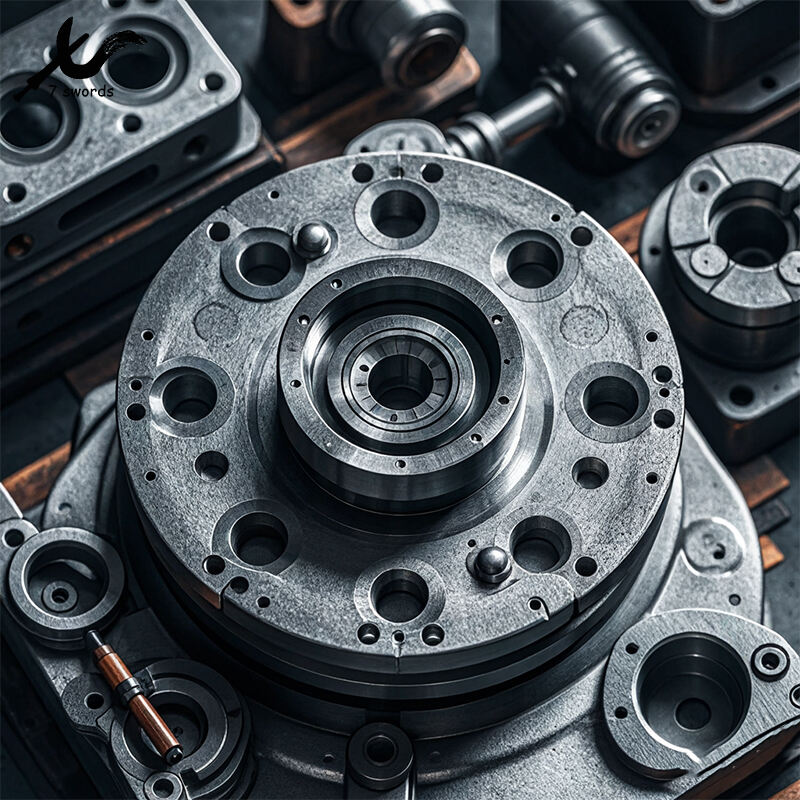

Mehrfach-Achsen-Fräsen von großen maritimen Ingenieurteilen:

Die Schiffbauingenieurkunst umfasst die präzise Bearbeitung schwerer mechanischer Komponenten, was den Einsatz von Mehrachsbearbeitungszentren erfordert. Dieser Artikel behandelt die Konzepte der Aufbausequenzen und Betriebsabläufe für die Bearbeitung und stellt einen logischen Ansatz zur Sequenzplanung und Maschinenzuordnung für große offshore-Bauteile vor.

Anwendung der Frästechnologie:

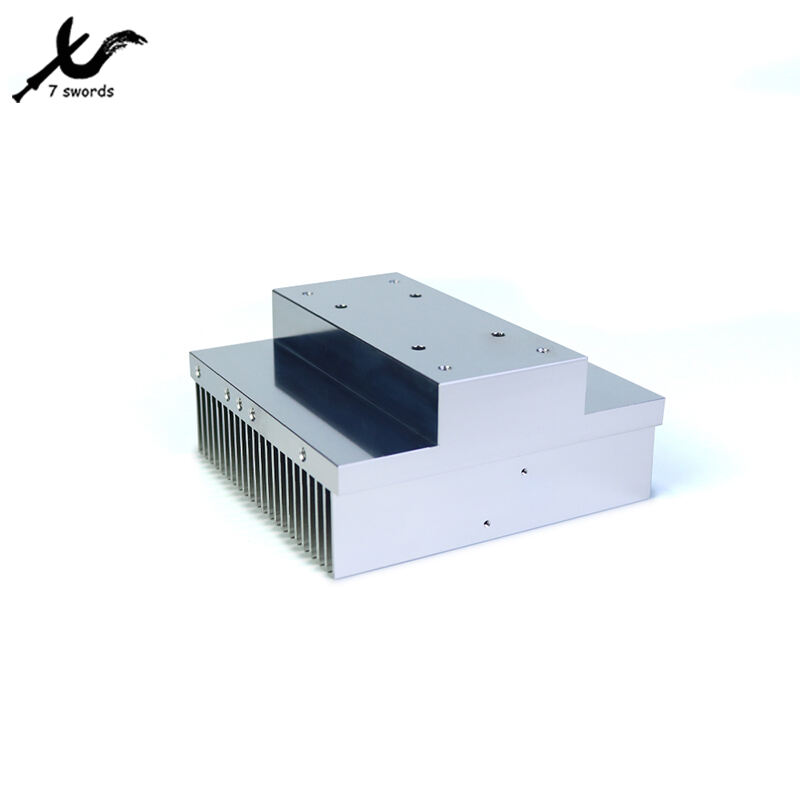

Präzisionsbearbeitung: Hochpräzise Bearbeitung ist essenziell für die Herstellung wichtiger Schiffsbauteile wie Propeller, Lagern und Getriebe mit höchsten Ansprüchen.

Materialvielfalt: Die Bearbeitungstechnologie ist vielseitig und in der Lage, eine Reihe von Materialien von herkömmlichen Metallen bis zu spezialisierten Legierungen zu verarbeiten.

Oberflächenbehandlung: Technologien wie Oberflächenverhärtung und Beschichtungen werden angewendet, um die Verschleiß- und Korrosionsbeständigkeit der Komponenten zu verbessern.

Individuelle Fertigung: Die Bearbeitungstechnologie ermöglicht die maßgeschneiderte Produktion von Teilen, um die spezifischen Anforderungen des Schiffbaus zu erfüllen.

Technologische Innovation und Vorteile:

Verbesserte Genauigkeit: Die Bearbeitungstechnologie gewährleistet die Präzision der Teilebearbeitung und entspricht den strengen Genauigkeitsanforderungen der Schifffahrtbranche.

Verbesserte Leistung: Die Anwendung spezieller Materialien und Oberflächenbehandlungstechnologien erhöht die Lebensdauer und Zuverlässigkeit von Schiffsbauteilen.

Kostensenkung: Durch optimierte Bearbeitungsverfahren wird Materialverschwendung minimiert, die Produktivität gesteigert und die Kosten gesenkt.

Erfolge und Auswirkungen:

Die Integration der Bearbeitungstechnologie hat die Leistungsfähigkeit und Qualität der Schiffsbauteile verbessert, was die Sicherheit und Effizienz von Schiffbau-Projekten stärkt. Sie fördert außerdem kontinuierliche Innovation und Fortschritte in den zugehörigen Fertigungstechnologien.

Fazit:

Die Einführung der Bearbeitungstechnologie in der Schifffahrtbranche ist ein Zeichen für technologische Kompetenz und uneingeschränktes Engagement für Prozessoptimierung und ingenieurtechnische Innovation. Mit fortschreitender Technologie steht der Schifffahrtsektor vor immer ambitionierteren ingenieurtechnischen Meilensteinen.