Präzisionszukunft: Der Aufstieg maßgeschneiderten CNC-Fräsen für fortschrittliche Verschlussteile

Nov.27.2024

Kurze Berührung zukünftiger Trends wie Automatisierung, intelligentes Fertigen und Industrie 4.0, die die CNC-Fräserprozesse prägen.

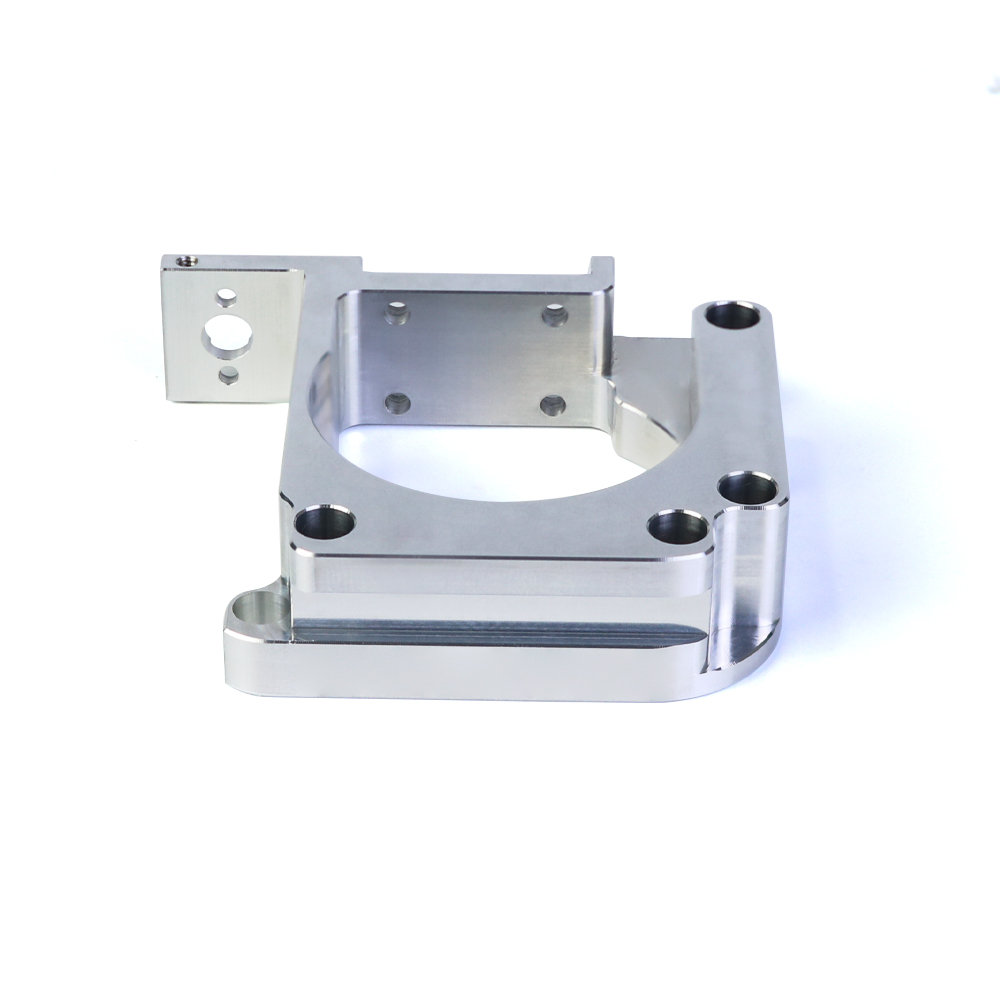

Die Rolle des maßgeschneiderten CNC-Fräsen in Präzisionsverschlusssystemen

1.Warum Präzision in Verschlusssystemen wichtig ist

- ·Erläutern Sie, wie Verschlusssysteme in Branchen wie Luft- und Raumfahrt, Automobilbau und industrielle Maschinenbauingenieurkunst präzise Ingenieurslösungen benötigen, um Sicherheitsstandards und Leistungsanforderungen zu erfüllen.

- ·Herausstellen von Beispielen wie Motorverschlüsse, sichere Gehäuse und Diebstahlschutzmechanismen.

2.Anpassung an spezifische Anforderungen

- ·Besprechen Sie, wie CNC-Fräsen die Möglichkeit bietet, hochgradig angepasste Verschlussteile wie komplexe Zahnräder, ineinandergreifende Komponenten oder manipulationsgesicherte Designs für spezifische Anwendungen zu entwerfen und herzustellen.

- ·Berühren Sie das Bedürfnis nach Prototyping und Kleinserienproduktion, die CNC-Fräsen effizient abwickelt.

Fortschritte in der CNC-Technologie für Präzision und Anpassungsfähigkeit

1.Mehrachsige CNC-Maschinen

- ·Beschreibe, wie 5-Achs-CNC-Fräsen die Erstellung komplexer Geometrien ermöglichen, die für Verschlusssysteme benötigt werden, wodurch von jedem Winkel aus Präzision gewährleistet wird.

2.Integration von KI und maschinellem Lernen

- ·Unterstreiche, wie künstliche Intelligenz gesteuerte CNC-Maschinen die Produktionsgenauigkeit verbessern und Werkzeugverschleiß vorhersagen können, was zu einer konstanten Qualität bei Verschlussteilen führt.

3.Materialinnovation

- ·Diskutiere Fortschritte in den Materialien, wie hochfesten Legierungen, Titan und Keramik, die CNC-Maschinen präzise verarbeiten können, um haltbare und leichte Verschlussteile herzustellen.

4.Additive Fertigung und hybride CNC-Lösungen

- ·Erwähne, wie das Kombinieren von CNC-Fräsen mit additiver Fertigung mehr Flexibilität bei der Herstellung komplexer Verschlussteile ermöglicht, mit weniger Materialbeschränkungen.

Anwendungen von maßgeschneiderten CNC-gearbeiteten Verschlussteilen

1.Automobilindustrie

- ·Nenne Anwendungen in Motorverschlüssen, Getriebeverschlusssystemen und Diebstahlschutzmechanismen, wo Präzision und Zuverlässigkeit von entscheidender Bedeutung sind.

- ·Erläutern Sie, wie Hersteller von Elektrofahrzeugen (EV) zunehmend leichte, präzise Verschlussteile fordern, um die Energieeffizienz zu optimieren.

2.Luft- und Raumfahrt sowie Verteidigung

- ·Besprechen Sie die Rolle von maßgeschneiderten Verschlussteilen in der Luft- und Raumfahrt, wo Komponenten strengen Sicherheits- und Leistungsstandards gerecht werden müssen.

- ·Herausstellen Sie Beispiele wie Fahrwerksschlösser, Türauslöser und Sicherheitssysteme für Motorhauben.

3.Anwendungen mit hoher Sicherheit

- ·Untersuchen Sie, wie CNC-Fräsbearbeitung genutzt wird, um manipulationsgesicherte Verschlusssysteme für Tresore, Safes und cyber-physische Systeme in Branchen wie Bankwesen und Datensicherheit herzustellen.

4.Industriemaschinen

- ·Konzentrieren Sie sich auf Verschlusssysteme für schwere Maschinen, Robotik und automatisierte Fertigungslinien, bei denen Präzision Zuverlässigkeit und Betriebssicherheit gewährleistet.

Herausforderungen bei der Fertigung von maßgeschneiderten CNC-Verschlussteilen

1.## Komplexität des Designs

- ·Erläutern Sie, wie das Design komplexer Verschlusssysteme eine enge Zusammenarbeit zwischen Ingenieuren und Herstellern erfordert.

2.Materielle Einschränkungen

- ·Herausforderungen bei der Bearbeitung bestimmter Materialien wie Superallegierungen oder Keramiken aufzeigen, die erweiterte Werkzeuge und Prozesse erfordern könnten.

3.Kosten und Skalierbarkeit

- ·Die Balance zwischen Anpassungskosten und Produktions skalierbarkeit diskutieren, insbesondere für Branchen, die kleine Chargen benötigen.

Zukünftige Trends in der Präzisions-CNC-Bearbeitung für Verschlussteile

1.Automatisierung und Industrie 4.0

- ·Vorhersage, wie intelligente Fabriken CNC-Bearbeitung mit Echtzeitüberwachung und datengetriebenen Erkenntnissen für eine effizientere Produktion integrieren werden.

2.Weiterentwickelte Materialien

- ·Erwähnung laufender Forschungen zu intelligenten Materialien und selbstheilenden Legierungen, die die Funktionalität und Haltbarkeit von Verschlussteilen verbessern könnten.

3.Nachhaltige Produktion

- ·Diskussion über den Trend hin zu nachhaltigen Bearbeitungsverfahren, wie zum Beispiel Reduzierung von Materialabfall und Steigerung der Energieeffizienz in CNC-Prozessen.