Κτίριο 49, Fumin Industrial Park, Pinghu Village, Longgang District

Κυριακή κλειστά

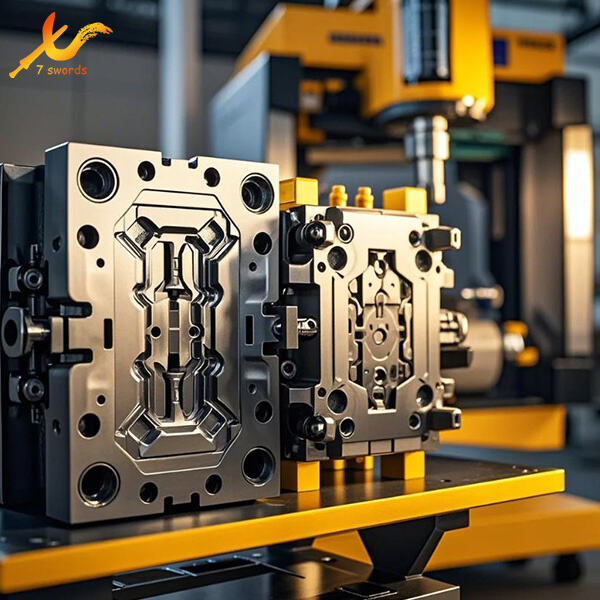

Have you ever wondered how things are mass-made? It’s really interesting! This is done by using a special tool known as a mould. A mould shapes and creates a number of identical objects — sort of like a cookie cutter, but on a larger scale and used for many different products. Moulds are essential in factories where bulk production of many items is done.

But you need to be accurate in design of mould. How one simple mistake can upset the whole system and ruin the final output. An example of this is that if a mould is improperly made, the items produced may not fit or function properly. That’s why we employ the state-of-the-art technology to ensure very high precision of our moulds. And we have unique instruments and tools which keep the track of the measurements to be accurate.

As much as organisation, innovation, or generating new ideas is also important in mould design. We are always looking through better and more efficient ways of making a mould work faster and smoother. Our team thinks outside the box to create creative solutions to any problem. That is to say, we are constantly trying to find new ways to enhance our moulds so that they can produce better and more efficient products.

Engineered to allow for a quicker & simpler manufacturing process. A good mould allows many identical objects to be made very quickly. This reduces time and money requirements since it enables factories to manufacture more products with less time consumption. Moulds that are designed smartly can also reuse materials, which helps the environment and companies save money.

Mould design relies a lot on the materials being used because they can affect the overall result of the final product. They deal with materials such as steel, aluminum, and plastic. Every material has unique properties that make it suitable for specific tasks. Steel, for instance, is very strong and durable, while plastic can be thin and flexible.

We also use various techniques such as injection moulding, blow moulding, and compression moulding. Each approach has its own advantages, depending on what we are trying to create. Injection moulding allows more complex shapes to be created, whereas blow moulding is often applied for producing hollow objects. We are able to tailor the moulds to meet the exact requirements of our clients by selecting the appropriate method.

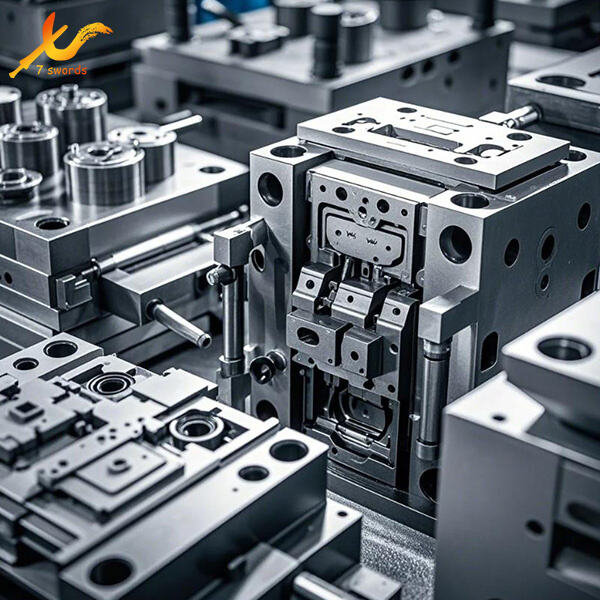

There are many steps in the mould design process, from concept to completion of the product. It starts by knowing what someone needs for an item. We collaborate with our clients to develop a design that is tailored to their requirements. These arrived after they were signed and part of the reason we need all of this collaboration for us to understand what their goals are, expectations.

We offer OEM and ODM services Minimum quantity of orders is one piece Mould Design are sent within three hours Sample production requires 1 to 3 days and bulk delivery can take 7 to 14 days Our production capacity for the month is more than 300 000 pieces

Mould Design have ISO9001 certificate, ISO14001, ISO45001, medical ISO13485, aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

We offer a variety of production equipment, ranging from 4-axis, 3-axis, and Mould Design. We offer a range of processing capabilities, including turning, milling, and grinding, drilling and EDM and 3D Printing. We work with a variety of different materials including aluminum, brass, copper as well as stainless steel, composites, plastics making parts that can meet every industrial requirement.

They have a wealth of experience and Mould Design to address all your questions. Their extensive knowledge and expertise will help you solve your concerns. Custom high-precision partsTolerances: +/- 0.1 mm, Special Space: +/0.005 mm

Πνευματικά δικαιώματα © Shenzhen Perfect Precision Products Co., Ltd. Με την επιφύλαξη παντός δικαιώματος — Πολιτική Προσωπικών Δεδομένων - Άρθρα