Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

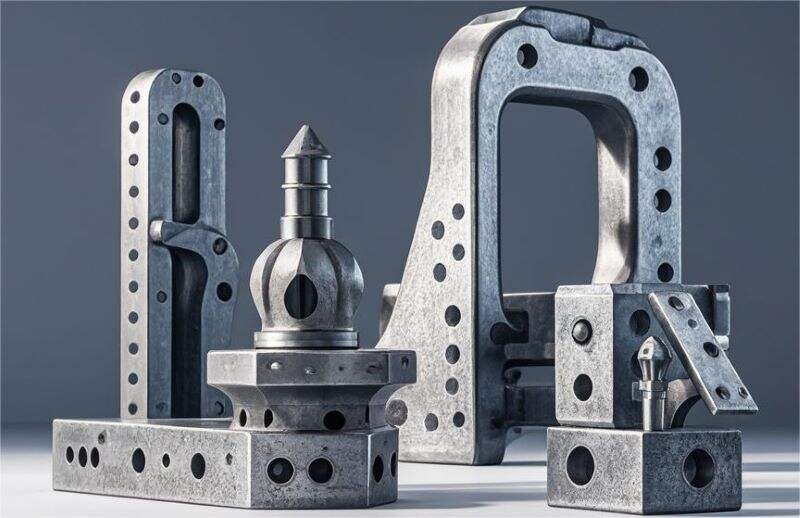

Forging machining services include processes that shape and refine forged components to achieve final specifications. Forging itself is a manufacturing process that uses localized compressive forces to shape metal. Machining, on the other hand, involves removing material from the workpiece to achieve the desired size and surface finish. Combining these processes can produce high-quality forged components suitable for specific applications.

Advantages of forging:

High strength and durability: Forged parts have excellent processing characteristics of high strength and durability, which can be the choice for parts that need to be used for a long time.

Precision: Products can be produced to the tolerances and dimensions required for the parts, ensuring that the parts meet precise specifications.

Versatility: It can be applied to a variety of metals, including steel, aluminum, titanium and alloys.

Cost-effectiveness: Combining forging with machining can optimize material use and reduce waste.

Forging services are used in a variety of industries, including:

Automotive: engine components, transmission components, steering and suspension parts.

Aerospace: landing gear components, structural parts, turbine blades.

Oil and gas: valves, fittings, drill bits and downhole tools.

Construction and infrastructure: structural components, fasteners and connectors.

Industrial equipment: gears, shafts, bearings and hydraulic components.

Choosing a forging service provider:

When choosing a forging service provider, consider the following factors:

Expertise and experience: Look for a supplier with extensive experience in forging operations.

Quality assurance: Check if they have a complete and reliable product quality control process to ensure that the quality of the parts meets the specifications.

Material capabilities: Confirm that they can use the materials required for your application, and consider factors such as material strength and corrosion resistance.

Cost and delivery time: Get quotes and evaluate their pricing competitiveness, and also check if they can produce and ship on time.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog