Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Dúnadh Dé Domhnaigh

Is é milling CNC próiseas máistreachta speisialta chun pródúictí a chruthú trí mheáin spéisiúla. Ar fud beag, tá na meáin seo bunaithe chun gach factor a bhogadh ó bhlocanna meála móra atá deacair a bholgadh, mar shampla stailt nó allaimh. Tá an cineál seo de chumhacht níos éasca ná na himeartha óna dtí seo, mar gheall air sin is féidir leo a phrogramáil (b'fhéidir nach bhfuil mé ceart anseo; táim ag dul ar mo thuiscint is fearr agus déanamh ráitis amháin). Eagraíonn sé seo dúinn a rá go héifeachtach cad éard a dhéanfaidh nuair a bhunaíonn sé rud, agus mar sin, má thugann muid léi foirméid chrua, gheobhaidh an t-ionsaí sin cúram orthu go cinnte. Is féidir le na himreoirí scileanna faoi láthair a chruthú agus i gcónaí iad a chruthú, rud a fhaighim uaireanta an-mhaith!

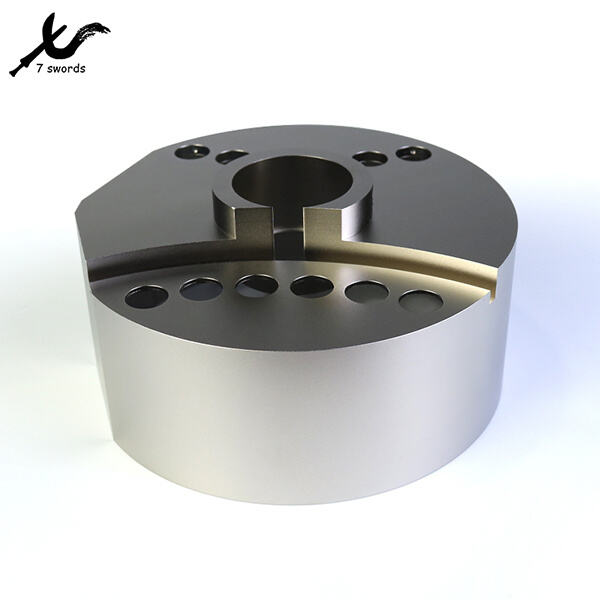

Is é sinneach na n-riomh seo ar fad cén fáth go bhfuil sé mar sin, a bheas gan amhras, na hathruithe iomchúite a chur in iúl ag úsáid mhinicíní CNC i lán-tionscal. Tá na hinicí seo ar fáil freisin mar aitheantas don scannal difriúil a chruthú gan stró. Is féidir le mhinicíní CNC píosaí ghníomhacha agus déileálainn dífhosta a chruthú nach féidir a dhéanamh ach trí thabhairt faoi phróiseas an duine. Mar sin féin, is léiriúil go bhfuil acmhainní CNC ar fáil as ucht an méid a bhfuil acu de chuid an chinntiúcháin. Is é sin a chiallaíonn go bhfuil cúigí níos lú agus mar sin tá ár n-earraí ag tabhairt searmanais den chéad scoth.

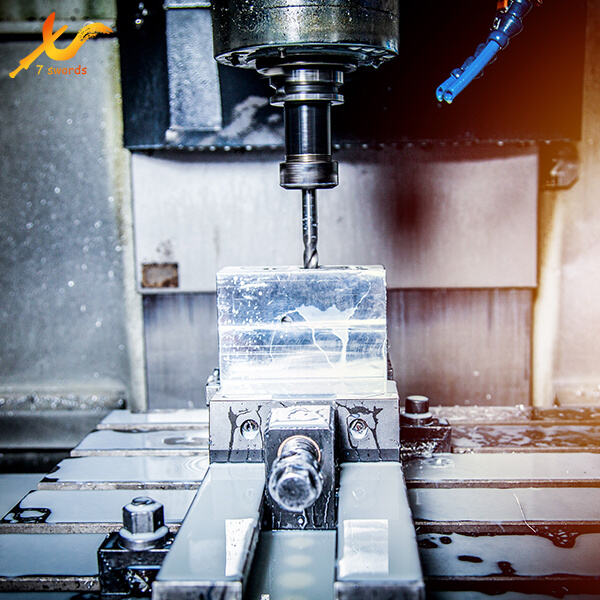

Anois, tá sé nádúrta cad é máilíní CNC. Tosaíonn sé le déanamh dízel an phróiséid a bhfuil tú ag plé le fabhricáil agus ansin scríobh clár ríomhaire a chuirfidh faoi deara an mhinicín dó chun an páirt sin a chruthú. Anois go bhfuil an clár réidh chun a bheith ag rith, cuir do phriomhphríomh inside an vise. Ansuithe seo, caithfidh tú an méid ceart a dhéanamh ar an ngníomhphríomh, a bhíonn againn ag caint gur féidir leat an toilgeála i gcónaí a chur isteach san ngníomhphríomh. Is é an rud eile nach bhfuil agat ach córas froidheadh a bheith ann, mar sin nach gcuirfear teocht orthu agus nach n-éiríonn leo a shuíomh nuair a gcuirtear i gcás.

Trí chéile leis an gcuideachta a bheith uait agus gach rud ceartaithe, tá sé amárach in am an mhinicíocht CNC a chas ar aghaidh. Gan amhras, níonnaíonn tú do chomhad isteach ar an mbinicíocht agus ligann tú dó é a fhoghlam agus tosaigh a chur ar fáil. Tá sé rialaithe ag an ríomhaire atá scailte ar chúl de, a chuirfidh i bhfeidhm na cinn cinnte agus an bord oibre i gcónaí le ceannóg atá déanta agat. Cuimsíonn comhad a bheith ag dul tríd an binicíocht CNC chun bloc alltrála a chruthú agus tarraingeadh suas le páirteanna a bhfuil measfocal ordughacha níos mó acu agus íoctha go hiomlán.

Mar sin, san gcás de mhachnaimh freastalaí CNC, tugaimid roinnt mionmhéid agus fíorchruthanna chun cabhrú leat an uirlis amháin is fearr a chur i bhfeidhm. An chéad ní atá ann ná go mba mhaith duit an prógram ceart a scríobh don phríomhphriobháid na n-earraí (cibé rud a úsáidfid). Mar shampla, cén scéal é conas tá an earra tinn nó cén scéal é conas éasca é a ghlacadh in aghaidh galladh. Ag breathnú ar na hathruithe seo, déanfaidh sé cinntiú ar na treoracha gearánaithe chun cinntiú go bhféadfadh do mhachnamh CNC cuaradh den earra go slán agus go ndéanfaidh tú páirteanna den chéad chuige go soiléir, ag dul chun cinn an tsaoil na n-inneall le haghaidh.

Agus tá na scileanna uile sin chun cabhrú le díriú ar do phróiseas CNC milling chun go mbeidh tú i gcónaí ag obair ar a n-áilleacht is fearr, gan éard a bheith agat faoi cheartlann an phríomhphréamh, gan amharc den fhadhbaithe poisteach a thabharfaidh cinntiú ar fad na n-ábhar. Ina laghairm eile, is féidir leis sin rá: brúchán a bhaint as an mbord oibre de na heolais cearta agus cur síos ar a chóras fuaróireachta go minic. Beidh sé seo chomh maith ag breathnú ar an easpa agus an úsáid, ag feabhsú an tuiscint agus ag dul i ngleic le h-éagsúlacht an phróiséis. Le CNC milling foilp-thacaíochta, beidh tú i gcónaí ag déanamh pearsaí ardchaighdeála gan aon chosc.

Ar deireadh, má nío bhfuil a-bharr agat a bheith in éineacht le do chonairí gnó, ansin caithfidh tú freastal ar phróiseáis CNC brú-sruth is cuspóireach freisin. Ag Swords Precision, tá roinnt den fheabhsú is láidre de na soiléir agus na hábhar inár dteideal a dtugann rís na próiseáis CNC brú-sruth is déanaí, agus atá i bhfeidhm ag foireann faoi láthair freisin. Is é sin go ndéanann na mion-mhéaduithe seo anois páirteanna a gcuirfidh i bhfeidhm go hiomlán níos fearr ná mar a rinneadar riamh, le níos mó deachtlú agus toradh níos fearr. Ní féidir páirteanna le leibhéal sochaide agus deachtlaithe seo a dhéanamh ach le feabhsuithe na hoibre is láidre a fheiceann tú ar ár n-equipment, agus cuireann siad brath suntasach ar fáil sa réimse faraor ina dtugtar amach go minic go bhfuil na páirteanna níos fearr nó níos lú ná na mion-mhéaduithe a chruthaigh iad.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved —Polasaí Príobháideachta —Blag