An bhfuil tú ag tuiscint faoi na polaiméar plaisteach? Iad suntasacha a chuireadh i bhfeidhm chun go leor níos gairid a chruthú, mar shampla tóin, botáin uisce agus fiú comhphléaráin gluaisteán! Tuiscint ar Chur an Cineál Ceart den Phlaisteach in Aghaidh Pródachtaí Le Preics Swords Tá go leor cineálacha éagsúla acu, agus is speisialt gach ceann de fhéin. Anseo roinnt samplacha de na cineálacha éagsúla de pholaiméar plaisteach agus cad atá speisialt aca.

Cineál amháin den phlaisteach is é polypropylene. Beidh muid ag caint faoi cineál láidre den phlaisteach, a dtugann taobh thairis air an téamperatúr ard gan briseadh. Is é seo an fáth a úsáidfear polypropylene go coitianta chun comhain bia a chruthú, mar sin nach gcuirfear i bhfeidhm chun sceideal a stóráil, agus comhain cruthaithe i gcarsa. An cineál eile den phlaisteach is é polystyrene. Is léiriúil an phlaisteach seo, a ligann cabhrú le h-ithreacht níos furasta agus níos éasca. Úsáid is ginearálta aici tá saor-iomlán mar phléidí agus cupóg, ach freisin i mbearta pacaíochta a choinneoidh míreanna sábhtha ar a n-imeacht.

Anois bímid ag imeartha ar pholietilin, atá soiléir ina plastic fosta féithiúil. Úsáidtear an cineál plastic seo chun go leor níos gach lá a chruthú, mar shampla coibhtheacha bainne, meaisín bruscar agus fiacail ghlacadh uile dúirt é sin a bhfuil orthu. Tá polietilin ní amháin láidir ach freisin cúlra oiriúnach, mar sin tá sé thar a bheith pobalachtach i rith maoiniú. Sa deireadh sin, tá Polivinil Clórid, nó PVC againn. Is é an téarma 'plastic fleabhrach' plastic a dtagann faoi chúram nach mbrisfidh nuair a théann sé chun caitheamh. Úsáidtear sé go minic chun piobta uisce a chruthú a churann an t-uisce chuig ár n-tithe mar sin féin mar phríomh-bhonn don chuid cábil idirlíon a chuirfidh fuaime ar ár gcuid giotagóid.

Cad is Speisial don Plastic

Anois go bhfuil tú tuarim a thuigeann na plastics éagsúla, féachaimid ar na feidhmíochtaí speisialta a bhaineann le gach ceann acu! Aigneimid faoi mar Swords Precision ar an gcuimhnigh ar pháistí na n-airt plastic nuair a bhíonn plástic ceart a roghnú do phroject. Is é sin a chuireann isteach go bhfuil an toradh sheasta sábháilte agus ag obair go ceart.

Mar shampla, pléamar cén fáth go bhfuil polipropíleán chrua go leor agus go bhféadfadh sé fuacht ard a chinntiú. Eiseamláir sin gur féidir a úsáid áite ar phlasteáin eile a mholódh nó a scailleadh. Tá polisteireán, ar an gceann amuigh, gloine agus féidir leis dul i ngleic le cúigéal éagsúla, ach ní hé sin chomh maith le cuid de na plasteacha eile. Mar sin is fearr é do úsáid gairid faoi rudaí atá cruthaithe chun baint amach. An bíonn tuiscint agat nach bhfuil polieitileán ag úsáid chun meacáin bainne a dhéanamh? Gan amhras, mar dhea gach rud a tharlaíonn, is maith a bheith láidre agus gloine, is iontach a bheith don pháircáil rudaí a bheidh ag bogadh timpeall.

Ba chóir duit gach uile nádúr den phlasteach seo a chur i gcomhair nuair a bheifeá ag roghnú plástach. Is tábhachtach í gcumhacht agus íochróga an phlasteach chun cinntiú cad is fearr é do pháirt shonracha den phroduct. Tá aitheantas le haicbhlóideanna seo ag cabhrú le heolaithe pleanálaíocht níos mí-shasta maidir le rogha máterial.

An tábhachtacht den chumhacht agus an iochróga

Is féidir é sin a chur i gcosaint go soiléir agus bíodh sé i gcuimhne ag tosú le rogha plastic don phróiseas tuarascáil, ag breathnú ar na n-éileamh chumhacht is fíor-dhlúth. Mar atá ráite, is cóir an plásic ceart a roghnú do úsáid laethúil mar chéim mhór chun níthe fada-tairiscint a chruthú a dtagann daoine ar fad ar feabhsuithe orthu!

Mar shampla, má nach bhfuil an plásic in ann comhluadar a thabhairt do gach uile rud seo, is féidir leis na héadóireachtaí scailleadh nó dul isteach go tapa. Ar bun le hataí páistí, b'fhéidir gur chóir don plásic a bheidh ag baint úsáide a bheith láidre go leor chun uaireantaí imirt fada a thuiscint. Is bródúil le páistí a gcuid áiteanna a chur faoi cháine, mar sin tá sé tábhachtach go mbeadh na hiomlán atá in eagraíocht acu láidre agus slán.

Díochlaonadh Teormaigh agus Ríochtaí

Tá neart eile den chéad fhadhb sa rogha pláscais é a chosaint ó theasaí agus ríochtaí. Ag Swords Precision, aitheas againn go bhfuil tú ag iarraidh plásic a roghnú a théann tríd timpeallachtaí bródúla chun cinntiú go bhfuil na pródaithe sábháilte agus déanfacha do chónraí.

Mar shampla, i mionscroide aeráide, tá plásca a fheidhmíonn ann. Deir Kushal freisin go gcaithfidh an cineál plásca seo tarlú ar ghriantús ard agus ar phléidhle agus benneán glas gan íoslódáil. Má n-annródhann an carr leis na seachnaithe seo, is dócha go gcuirfidh sé rudaí scandaílacha. Mar shampla, caithfidh an plásca a úsáidfear chun neamhspré a stóráil bheith tuillte le díomá an chineál spré chun pailéad agus scolb a chur chun cinn.

Costas agus Cura Oileán

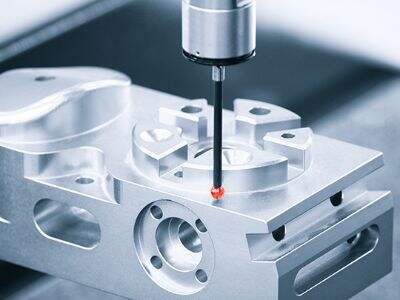

Déanaimid an méid dár deireadh i gcás Swords Precision páirteanna máinigh cnc , feiceann muid freisin cad é mar atá an plásca costas-droimh agus conas atá sí ag impact ar an domhan timpeall. Fós, cé go bhfuil cuid den phlásc á chruthú go soiléir agus go héasca, bíonn ionchapa toxiciúil acu ar ár bpianet.

Firmí féiniúlacht CNC ná bíonn é ina bhfeidhm ag leithéid den chomhaid. Ach is maith léi an timpeallacht, mar gheall ar na himreataí dochtúla atá inti agus nach bhfuil a leithéid éadrom le hiompar. Tá cuid mhór dár n-údairc ag lorg plástach eile, a bhfuil sé ceart don eolaire agus nach gcuirfear siar go mór ar fhoirmannaí dochtúla. Caithfidh na cuideachtaí comórtas a thabhairt faoi choinníollacha mar seo nuair a bheidh ag roghnú máthar don ár n-údairc.

Tabhair tómhladh San tráthnóna, beidh roghnú ar an plástach is fearr don chruthú ag teastáil tuiscint de réimse dlúthchainte plástach nó polaiméar plástach mar aon le cúram an tíre, cruth, costas, agus infhéarann timpeallachta. Sa Swords Precision, brúimid ar ár gcás agus ár n-éispéireas chun cabhrú lenár gcustaiméirí i dtabhairt amach ar an plástach ceart a chloíonn go soiléiri leis an gceangal. Go raibh maith agat as ucht teacht linn inniu chun foghlaim!