Conas Úsáid Cinneadh CNC Chum Cinneadh Siubhálaigh Fiontracha A Bhaint Amach

Chuir an obair le CNC (Ríomhaire Úsáideach Námhacht) réabhlóid i dtreo na n-iompóiríocht phrionsabalta, go háirithe i bhfoirm phearsaí uas-rialtaithe a chruthú. Tugann an teicneolaíocht seo ar aghaidh tacar scileanna nach mbaineann le brón agus éifeachtacht gan choinne, agus is féidir léi baint leis an obair de ghnéithe eisiúnaigh agus nádúrtha. I gcás an alt seo, beidhimid ag feabhsú ar na córsa príomhacha agus na béistí is fearr chun úsáid a bhaint as CNC machining chun phearsaí uas-rialtaithe a chruthú.

Tuiscint ar Thábhacht na nGearra Uas-rialta

Tá gearra mar chuid shainchrua den scagaire meicniúla, lena n-áirítear carr, speisialtacht speisialtacht agus feabhsuithe iompar. Is féidir le hionannacht na ngearra seo a chur isteach ar fheabhsuithe, éifeachtacht agus fadhbhail an chóras go léir. Gears uas-rialta cinntiú oibriú glan, laghdú fuaim agus laghdú caitheamh agus crith.

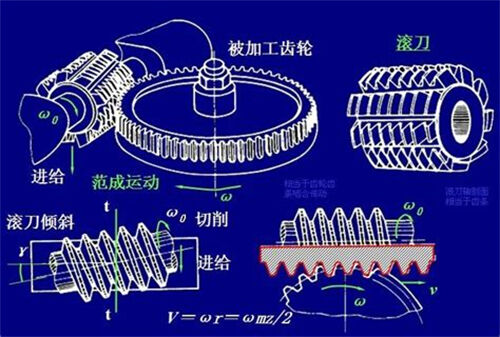

An Ról a Chuireann CNC Machining i gCás Gear Production

Tá cúigreacht ag CNC machining faoi láthair nuair a thagann sé chun phearsaí uas-rialtaithe a chruthú:

Níos Fíor agus Consistency: Is féidir le hinneall CNC éacht uasleasaithe a bhaint amach, go minic faoi mhicrona. Is mofhaisnéiseach an tsamhail seo don ghnéitheanna foirfeála, áit ar bith go bhfuil sé bródúil go ndéanfaidh méaduithe beaga fosta cinntiú ar phriomhshuíomh na n-úsáid.

Gníomhaíochtaí Cnámhach: Is féidir le hingearradh CNC díbirt le gníomhaíochtaí cnámhach agus léaráidí tábhachtacha atá deacair nó neamhbhríomhar a dhéanamh le meastóireacht dírithe. Tá an cumas seo sna háiteanna is tábhachtaí don ghnéitheanna foirfeála speisialta a úsáidtear i láránnaíocht ardpherfórmáid.

Fliuchas Mhatéarál: Is féidir le hinneall CNC oibriú le raon leathan matadál, lena n-áirítear meital, plásca agus comhpleabhsanna. Déanann an fliuchas seo cabhrú le tograírí matadál is feiliúnach a roghnú don chás pearsanta.

Eisiollaíocht agus Luas: Tá ingearradh CNC níos tapa ná na meastóireachtaí dírithe, ag cúlú ama phróiseála agus costais. Tá an tuaslag seo níos mó ná riamh mar thoradh airgeadú saor in aisce.

Gaidhín Chéim faoi Chéin chun Eolus Ardchraiceála Ghear Macháin a Bhaint Amach le CNC

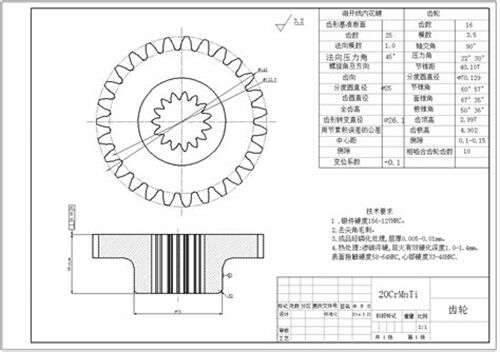

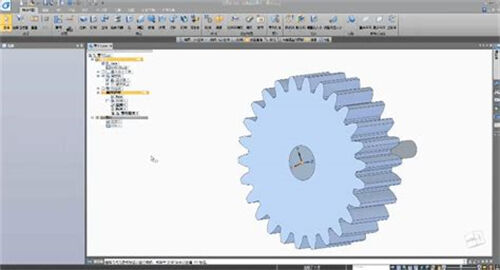

Céim 1: Dízel agus Similé

Roimh a lorg an phróiseas mácháiníochta, tá sé riachtanach plán áitiúil a chruthú agus smaoineamh a dhéanamh chun cinntiú go ndéanann an fhiol tríd na spéisiúin uile atá acu. Is féidir bogearraí CAD (Computer-Aided Design) a úsáid chun módéilí níos príobháideacha a chruthú agus buntáistí idirnáisiúnta a bhailiú sula dtosaíonn an tuarascáil.

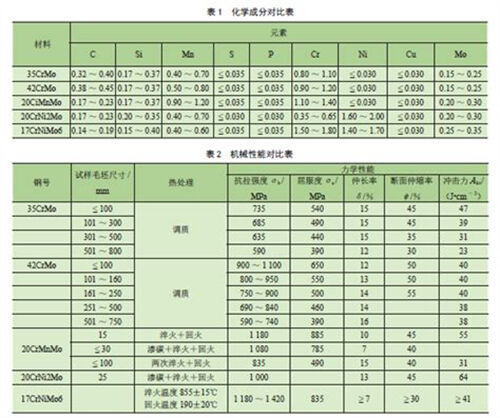

Céim 2: Roghnú Mhatéadál

Roghnaigh an mhatéadál ceart bunaithe ar na riachtanais úsáide. I measc na n-mhatéadálacha coitianta do phróiseas fiol a chríochnú tá stál, alcamain agus títail. Tá gach mhatéadál a leithéid féin de phriomhréimsí agus brabús, mar sin is éigin an rogha ceart a dhéanamh.

Céim 3: Inbhe agus Socrú

Roghnaigh na heiscintithe cearta agus socraigh an mhachan CNC i gcomhar le díbhriú an fhiol. Tagraíonn an céim seo rogha an tspeis eiscint, luas fóil, agus gairid an eiscint chun cinntiú taithí óil agus beatha na n-eiscintithe.

Céim 4: Phróiseas Mácháiníochta

Néillig an phróiseas mácháiníochta ag úsáid an mhachan CNC. D'fhéadfadh sé seo a chinntiú go bhfuil gníomhaíochtaí níos mó ina bhfuil páirt le hól, druliú agus glanadh chun an cruth agus an fiontrú scátháin is fearr a bhaint amach.

Céim 5: Seiceáil agus Rialú Gníomhachta

Tar éis an tsheiceála, seiceál na gcriosóg ag baint úsáid as teicniocaithe measúnachta láidre, mar shampla, fuaiseanna a mhéadú co-ordaithe (CMMs) nó scannáil le laistigh. Déanann an céim seo cinntiú go ndéanann na criosóga gach spéisiúlacht agus go bhfuil siad réadha do chur i gcás nó do phróiseas breise.

Céim 6: Póstaíocht

Déan cinnte go dtabharfaidh na córsa próiseas póstaíochta bríomhar, mar shampla, treabhsú théarmuigh, críochnú fáisnéise nó cúmhrú, ar pháirteacht agus ar fhostaíocht na gcriosóg.

Feabhsuithe agus Staidéir Chás Sa Ghéarchéim

Tús maith amháin é an obair atá déanta ag Anthony Usher de MEC CNC, a chuidigh beagnach le custaiméirí tríd an phróiseas cruthú CNC simplí donn sinne nach raibh taithí roimh réamh acu ar ríomhaireacht. D’fhíorú an méid seo géagán mór sa mballstát, ag cinntiú go bhfuil meaisiú gníomhachta criosóg inrochtana do lucht níos leithne de thionscadail.

Is é brúchán éagsúil CNC chun obair ghníomhach de phraiticiúl a bhaint amach. Trí thuiscint a fháil ar thábhacht na praiticiúla, úsáid na hathrúchán a thugann an teicneolaíocht CNC agus iarracht a dhéanamh ar phróiseas struchtúrtha don dízel, roghnú fhréamh, uirlisí, gníomhach, seiceáil agus óstach ina dhiaidh sin, is féidir le tograíodóirí gníomhanna den chothromas a chruthú a mbeidh méadú i gcás bealaí éagsúla. Cén tuairim atá agat nó cén tuairim atá agat, bíonn maith le foghlaim faoi bhrúchán CNC chun gníomhanna a chruthú nua oportunitíochtaí agus neamhspleáchacht a oscailt.

Tábla Ábhar

- Conas Úsáid Cinneadh CNC Chum Cinneadh Siubhálaigh Fiontracha A Bhaint Amach

- Tuiscint ar Thábhacht na nGearra Uas-rialta

- An Ról a Chuireann CNC Machining i gCás Gear Production

- Gaidhín Chéim faoi Chéin chun Eolus Ardchraiceála Ghear Macháin a Bhaint Amach le CNC

- Feabhsuithe agus Staidéir Chás Sa Ghéarchéim