Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

As demand for high-quality, customized gears grows, manufacturers are turning to advanced technologies and tailored solutions to stay ahead in a competitive market. This article explores how factory-customized gear manufacturing is revolutionizing the industry and why it’s the key to unlocking superior performance and efficiency.

The Importance of Precision in Gear Manufacturing

Gears are more than just metal components; they are the backbone of mechanical systems. Whether it’s a small gear in a medical device or a massive gear in a wind turbine, precision is non-negotiable. Even the slightest deviation in design or production can lead to inefficiencies, increased wear and tear, or even system failure. This is where customized gear manufacturing shines.

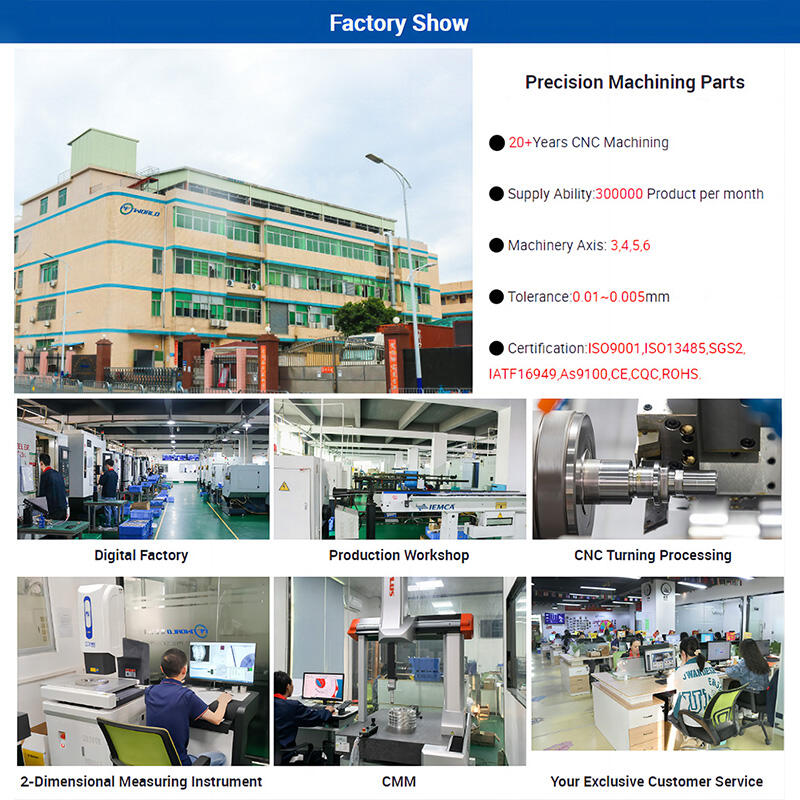

By leveraging state-of-the-art CNC machining, 3D modeling, and advanced materials, manufacturers can produce gears tailored to specific applications. Customization ensures that each gear meets exact tolerances, operates seamlessly within its intended system, and delivers optimal performance under varying conditions.

Why Choose Factory-Customized Gear Manufacturing?

1.Tailored Solutions for Unique Needs

No two industries or applications are the same. Factory-customized gear manufacturing allows businesses to design gears that align perfectly with their operational requirements. Whether you need gears with unique tooth profiles, specific heat treatments, or specialized coatings, customization ensures your gears are built to last.

2.Enhanced Performance and Durability

Custom gears are engineered to withstand the specific stresses and strains of their intended use. This results in longer lifespans, reduced maintenance costs, and improved overall efficiency. For industries like automotive and aerospace, where reliability is paramount, this is a game-changer.

3.Cost-Effectiveness in the Long Run

While off-the-shelf gears may seem like a cost-effective solution upfront, they often lead to higher expenses due to frequent replacements or system downtime. Custom gears, on the other hand, are designed to integrate seamlessly into your machinery, reducing the risk of failures and saving money over time.

4.Faster Turnaround Times

Modern gear manufacturing facilities equipped with advanced technologies can produce customized gears quickly and efficiently. This means shorter lead times and faster delivery, helping businesses stay on schedule and meet project deadlines.

Innovations Driving the Future of Gear Manufacturing

The gear manufacturing industry is undergoing a transformation, thanks to cutting-edge innovations. Here are some of the trends shaping the future:

·Additive Manufacturing (3D Printing): This technology allows for the rapid prototyping and production of complex gear designs that were previously impossible to achieve with traditional methods.

·Smart Manufacturing (Industry 4.0): IoT-enabled machines and AI-driven analytics are optimizing production processes, ensuring higher precision and reducing waste.

·Sustainable Practices: Manufacturers are increasingly adopting eco-friendly materials and processes to reduce their environmental footprint while maintaining high-quality standards.

Partnering with the Right Gear Manufacturing Expert

Choosing the right partner for your gear manufacturing needs is crucial. Look for a manufacturer with a proven track record of delivering high-quality, customized solutions. Key factors to consider include:

·Expertise in a wide range of materials (steel, brass, plastic, etc.)

·Advanced machining capabilities (CNC, hobbing, grinding, etc.)

·A commitment to quality control and precision

·The ability to scale production to meet your demands

In a world where precision and efficiency are paramount, factory-customized gear manufacturing is the key to staying competitive. By investing in tailored solutions, businesses can ensure their machinery operates at peak performance, reduce downtime, and achieve long-term cost savings.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog