Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Micro Machining or Not Micro Machining

Model Number:Custom

Material:Titanium Alloy

Quality Control:High-quality

MOQ:1pcs

Delivery Time:7-15 Days

OEM/ODM:OEM ODM CNC Milling Turning Machining Service

Our Service:Custom Machining CNC Services

Certification:ISO9001:2015/ISO13485:2016

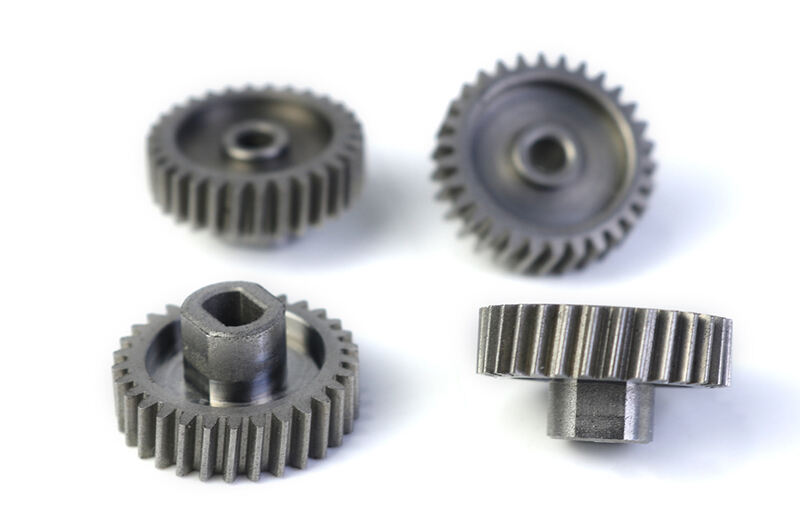

When it comes to power transmission systems, efficiency, precision, and durability are paramount. Among the various gear types available, helical gears stand out as one of the most widely used and reliable solutions for transmitting torque between shafts. Known for their smooth operation and high load-bearing capacity, helical gears are essential components in various industries, including automotive, manufacturing, aerospace, and heavy machinery. In this article, we’ll explore the benefits and applications of helical gears and why they should be an integral part of your power transmission system.

A helical gear is a type of gear with teeth that are cut at an angle to the axis of rotation. Unlike straight-cut gears, whose teeth are parallel to the axis, the angled teeth of a helical gear allow for smoother and more gradual engagement with the teeth of the mating gear. This design results in less vibration, lower noise levels, and more efficient power transfer.

The helical tooth pattern allows multiple teeth to be in contact simultaneously, distributing the load more evenly and reducing wear. This results in a gear that not only runs quieter but also provides enhanced strength and durability.

1.Smooth and Quiet Operation

One of the most significant benefits of helical gears is their smooth and quiet operation. The angled teeth engage gradually, which reduces the shock and noise typically associated with straight-cut gears. This makes helical gears ideal for applications where low noise levels are critical, such as in automotive transmissions, industrial machinery, and precision equipment.

2.Higher Load Capacity

Because multiple teeth are engaged at once, helical gears can handle higher loads compared to straight-cut gears. This makes them ideal for high-performance applications where torque and load demands are substantial. Whether in a heavy-duty industrial machine or an advanced aerospace system, helical gears provide the necessary strength and reliability for demanding tasks.

3.Efficient Power Transmission

Helical gears are known for their superior efficiency. The angle at which the teeth mesh allows for better force distribution, resulting in less energy loss due to friction. This means less wear on components and better overall energy efficiency, making helical gears a smart choice for long-term cost savings in energy-intensive applications.

4.Higher Speed Capabilities

Helical gears are designed to handle higher speeds than straight-cut gears. The gradual meshing of the teeth allows for smoother transitions in speed, making helical gears suitable for high-speed applications such as automotive transmissions and machinery in manufacturing environments.

5.Ability to Handle Parallel and Non-Parallel Shafts

While helical gears are commonly used to transmit power between parallel shafts, they can also be designed to function with non-parallel shafts. By using bevel helical gears, manufacturers can efficiently transfer power between shafts at different angles, expanding the versatility of helical gears in various mechanical systems.

1.Automotive Industry

In automotive applications, helical gears are frequently used in manual and automatic transmissions, differential gears, and power steering systems. Their quiet operation and ability to handle high loads make them ideal for improving performance and driving comfort in vehicles.

2.Industrial Machinery

Helical gears are integral to industrial machinery that operates under high loads and speeds, including conveyors, pumps, and compressors. The reduced vibration and wear make them perfect for applications where precision and durability are critical.

3.Aerospace and Aviation

In aerospace, helical gears are used in gearboxes and engines, where efficiency and reliability are paramount. The ability of helical gears to handle high loads and operate smoothly at high speeds is essential for the demanding conditions of aerospace systems.

4.Heavy Equipment

Helical gears are also found in heavy equipment like construction machinery, mining equipment, and agricultural machinery. The rugged design and ability to transmit high torque make them ideal for applications in harsh and demanding environments.

5.Renewable Energy

In renewable energy applications such as wind turbines, helical gears are used in the transmission systems to convert the mechanical energy generated by wind into electrical energy. Their ability to operate efficiently in high-torque and high-speed conditions makes them ideal for this application.

Helical gears are essential components in modern power transmission systems, offering a range of benefits from smooth operation to high load capacity. With their ability to deliver efficient, reliable, and durable performance across various industries, helical gears are the go-to choice for many applications, from automotive to aerospace.

Opting for factory-customized helical gears ensures that your system operates at its best, providing optimized performance, greater efficiency, and longer-lasting results. Whether you’re looking to improve the performance of a vehicle, machinery, or energy system, custom-engineered helical gears are a smart investment for achieving precision and reliability in your power transmission systems.

Invest in high-quality, factory-customized helical gears and experience the difference in performance, durability, and efficiency that precision engineering brings to your operations.

Q:Can helical gears improve the performance of my vehicle or machinery?

A:Yes, helical gears can significantly improve the performance of your vehicle or machinery. They enhance the efficiency of the power transmission system, resulting in better torque distribution, smoother operation, and improved power output. In automotive applications, for example, the use of helical gears in the gearbox or differential can provide more reliable acceleration and smoother shifts.

Q:How do I know which helical gear is right for my tuning system?

A:The right helical gear for your tuning system depends on several factors:

Material: Depending on the stress and environment, you may need materials like stainless steel, titanium, or specialty alloys.

· Gear Ratio: The gear ratio impacts torque and speed, so consider what balance you need between acceleration and top-end speed.

· Size and Teeth Configuration: Ensure the size and tooth configuration of the helical gear matches your system’s specifications. Customization is often needed for perfect integration into your tuning setup.

Q:Can I install helical gears myself, or do I need professional help?

A:Installing helical gears can be a complex process that requires precision. While some enthusiasts with advanced mechanical knowledge might be able to install the gears themselves, it's generally recommended to seek professional installation, especially for custom gears. Professionals ensure that the gears are installed correctly, preventing issues like misalignment, which can lead to inefficiency or damage to the system.

Q:Are helical gears compatible with all vehicles or machinery?

A:Helical gears can be used in a wide range of vehicles and machinery, but compatibility depends on the specific design and setup of the system. They are commonly found in high-performance automotive gearboxes, heavy machinery, and power transmission systems. However, it's essential to ensure that the helical gears you choose are designed for your system's specific requirements, such as load capacity, speed, and gear ratios.

Q:Are helical gears more expensive than other types of gears?

A:Factory-customized helical gears may cost more than standard straight-cut gears due to the precision required in manufacturing and the materials used. However, their benefits—such as smoother operation, higher load capacity, and greater durability—often justify the higher cost. Additionally, the efficiency and performance improvements they provide can lead to longer-term cost savings by reducing the need for frequent repairs or replacements.

Q:How long do helical gears last in high-performance systems?

A:The lifespan of helical gears in high-performance systems depends on various factors, including the materials used, the load they handle, the speed at which they operate, and how well the system is maintained. With proper care, high-quality helical gears can last for many years, even in demanding applications. Regular maintenance, including lubrication and inspection, can extend their lifespan and ensure continued peak performance.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog