उच्च-शुद्धि निर्माण अनुप्रयोगों के लिए सर्वो मिलिंग प्रौद्योगिकी का अन्वेषण

Nov.27.2024

सर्वो मिलिंग और शुद्धता विनिर्माण को संक्षिप्त रूप से परिभाषित करें, आज की उच्च-तकनीकी उद्योगों में उनके महत्व पर बल दें।

शुद्धता विनिर्माण की भूमिका

1.परिभाषा और महत्व

- ·शुद्धता विनिर्माण को ऐसी प्रक्रिया के रूप में परिभाषित करें जो अत्यधिक सटीक सहनशीलता और संगत गुणवत्ता वाले भागों का उत्पादन केंद्रित करती है।

- ·इसके उपयोगों पर बल दें जैसे विमान उद्योग (इंजन घटक), चिकित्सा उपकरण (ग्राफ्ट, शल्य उपकरण) और इलेक्ट्रॉनिक्स (माइक्रोचिप, सेंसर)।

2.शुद्धता विनिर्माण के फायदे

- ·उन्नत उत्पाद गुणवत्ता : संगत सहनशीलता उत्पाद की बेहतर प्रदर्शन और अधिक जीवन की अपेक्षा लाती है।

- ·लागत दक्षता : अधिक आरंभिक लागत के बावजूद, शुद्धता विनिर्माण सामग्री के अपशिष्ट और उत्पाद दोषों को कम करता है, जिससे दीर्घकालिक खर्च कम हो जाते हैं।

- ·उद्योग की पालन-पालनी : सुरक्षा और विश्वसनीयता के लिए कठोर उद्योग मानकों को पूरा करता है, जैसे ISO प्रमाणपत्र और नियमित आवश्यकताएं।

सर्वो मिलिंग और प्रसिद्धता निर्माण के अनुप्रयोग

1.एयरोस्पेस

- ·बताएं कि सर्वो मिलिंग को इंजन ब्लेड, हवाई जहाज़ के फ्रेम और लैंडिंग गियर घटकों जैसी उच्च-शुद्धता के भागों को बनाने में कैसे उपयोग किया जाता है।

- ·ताँबा और एल्यूमिनियम एल्युओइज़ जैसी हल्की वजन की लेकिन रोबस्ट सामग्रियों की आवश्यकता का उल्लेख करें, जिनके लिए सटीक मशीनी कार्य आवश्यक है।

2.चिकित्सा उपकरण

- ·उल्लेख करें कि सटीक निर्माण चिकित्सा उपकरणों, प्रोस्थेटिक्स और ग्राफ्ट्स के उत्पादन में ठीक-ठीक मानकों का पालन कैसे करता है।

- ·सर्वो मिलिंग की भूमिका का चर्चा करें जो चिकित्सा भागों को बनाने में मदद करती है, जो जीव-अनुकूल (biocompatible) और जटिल आकार के होते हैं।

3.ऑटोमोटिव

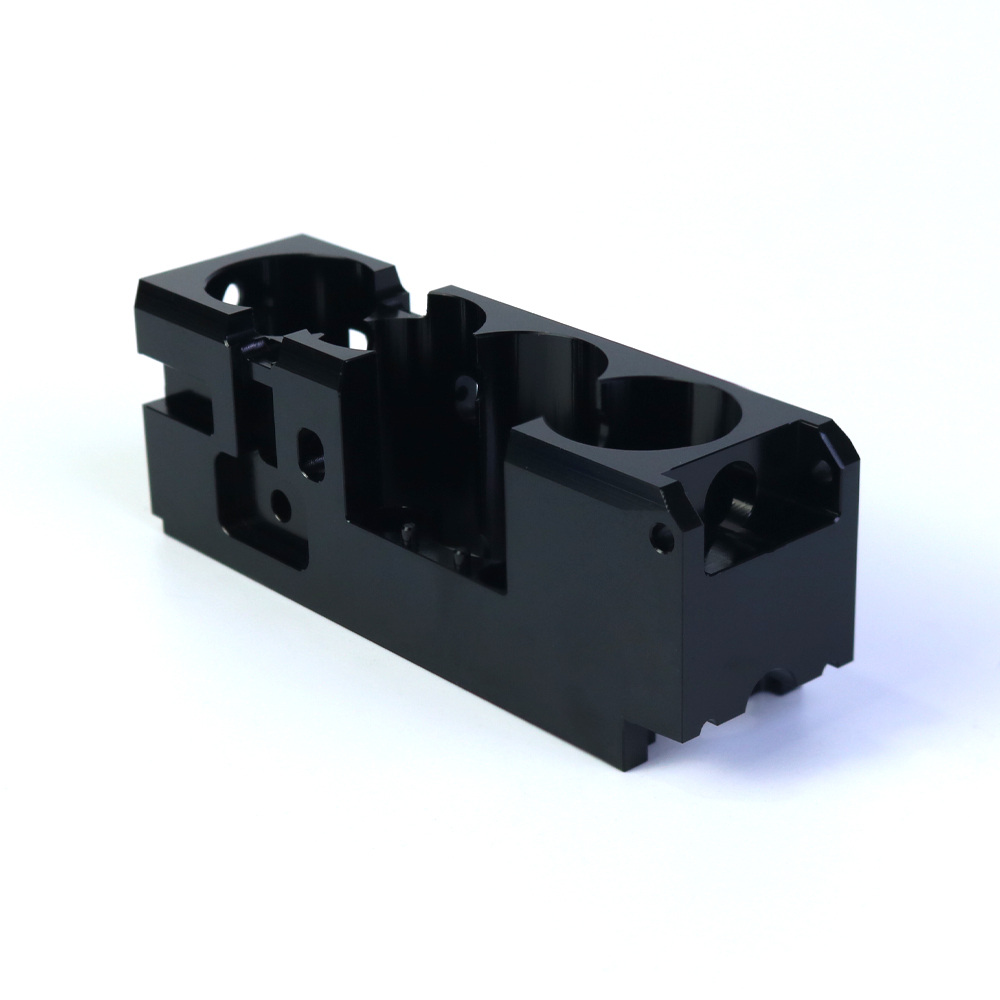

- ·इंजन घटक, गियर प्रणाली और EV बैटरी केसिंग जैसे अनुप्रयोगों का वर्णन करें, जो शुद्ध अनुपात और सटीक मशीनी कार्य से लाभ पाते हैं।

- ·सर्वो मिलिंग के योगदान पर बात करें, जो इलेक्ट्रिक वाहनों (EVs) के लिए हल्के वजन के, उच्च-शक्ति भागों के विकास में मदद करता है।

4.इलेक्ट्रानिक्स

- ·जांचें कि सर्वो मिलिंग और सटीक निर्माण उन्नत इलेक्ट्रॉनिक्स के लिए माइक्रो-घटक, हीट सिंक और सेमीकंडक्टर वेफरों का उत्पादन करने में कैसे महत्वपूर्ण है।

सर्वो मिलिंग और सटीक निर्माण में प्रौद्योगिकी के विकास

1.AI और मशीन लर्निंग के साथ एकीकरण

- ·चर्चा करें कि AI-शक्तिशाली CNC प्रणालियां डेटा विश्लेषण का उपयोग कैसे करके सर्वो मिलिंग प्रक्रियाओं को बेहतर बनाती हैं, कुशलता में सुधार करती हैं और बंद होने के समय को कम करती हैं।

2.स्मार्ट कारखाने और स्वचालन

- ·सर्वो मिलिंग प्रणालियों को स्वचालित उत्पादन लाइनों में जोड़ने में उद्योग 4.0 की भूमिका का उल्लेख करें, जिससे वास्तविक समय में निगरानी और सुरक्षित मशीनी कार्य करना संभव हो।

3.उन्नत सामग्री और उपकरण

- ·सर्वो मिलिंग के साथ सटीकता के साथ काम करने वाले कटिंग उपकरणों (जैसे, डायमंड-कोटेड उपकरण) और सामग्रियों (जैसे, सुपरएलोइज़, कम्पाउंड) में नवाचारों को प्रमुख बनाएं।

चुनौतियाँ और समाधान

1.उच्च प्रारंभिक निवेश

- ·सर्वो मिलिंग प्रौद्योगिकी और उन्नत CNC प्रणालियों के लागत को स्वीकार करें।

- ·सरकारी सब्सिडीज़, लंबे समय तक ROI और सस्ते सर्वो प्रणालियों में प्रगति जैसे समाधानों का प्रस्ताव दें।

2.कुशल श्रमबल

- ·CNC प्रोग्रामिंग और सर्वो प्रणाली रखरखाव में कुशल ऑपरेटरों की आवश्यकता के बारे में चर्चा करें।

- ·प्रशिक्षण कार्यक्रमों और शैक्षणिक संस्थानों के साथ साझेदारी जैसे हलों का प्रस्ताव दें।

सर्वो मिलिंग और सटीक निर्माण में भविष्य की रुझान

1.लघुकरण

- ·माइक्रोइलेक्ट्रॉनिक्स और मेडिकल नैनोटेक्नोलॉजी जैसी उद्योगों में छोटे, अधिक सटीक घटकों के लिए बढ़ती मांग का पता लगाएं।

2.स्थिरता

- ·चर्चा करें कि सटीक निर्माण और सर्वो प्रणालियां कैसे अपशिष्ट और ऊर्जा खपत को कम कर रही हैं, हरित निर्माण लक्ष्यों के साथ मेल खाती हैं।

3.हाइब्रिड मैन्युफैक्चरिंग

- ·बताएं कि सर्वो मिलिंग को अभिजात निर्माण (3D प्रिंटिंग) के साथ मिलाने से जटिल घटकों को बनाने में कैसे लचीलापन और सटीकता मिलती है।