Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Model Number:OEM

Keyword:CNC Machining Services

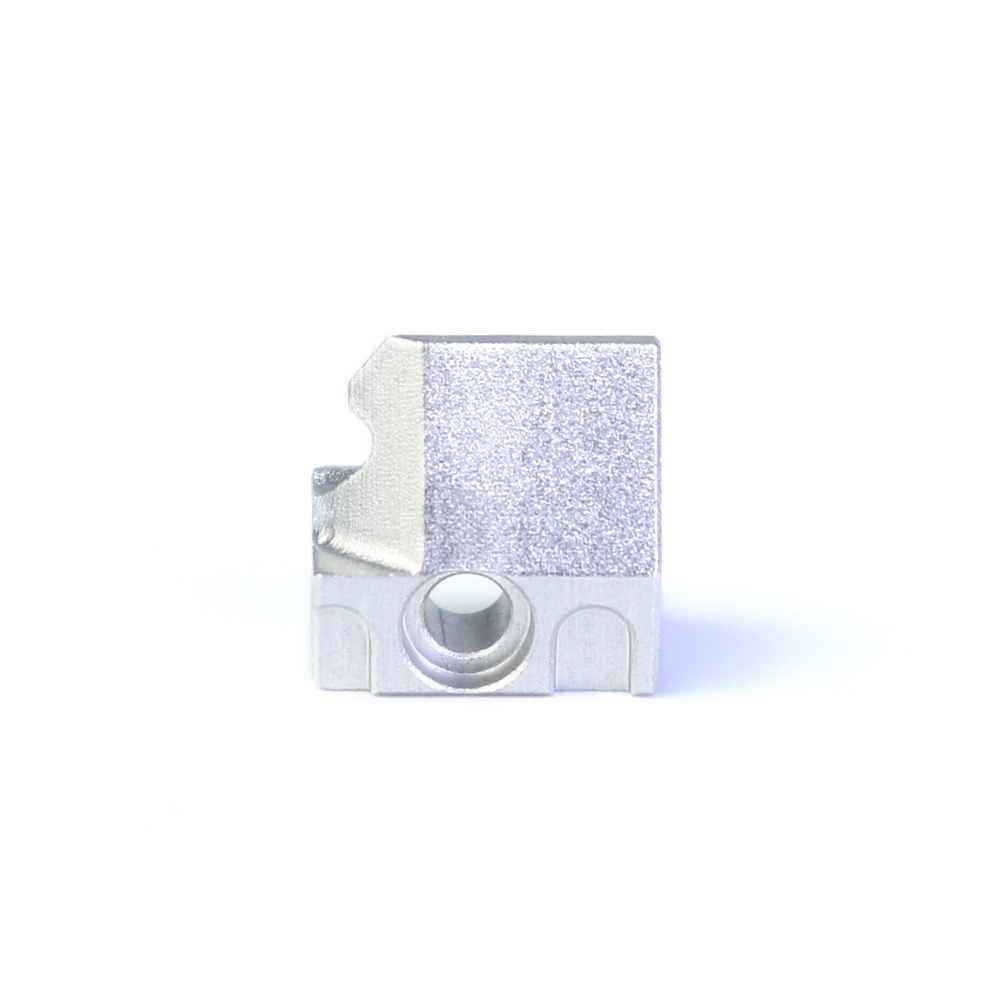

Material:Aluminum alloy

Processing method :CNC milling

Delivery time:7-15 days

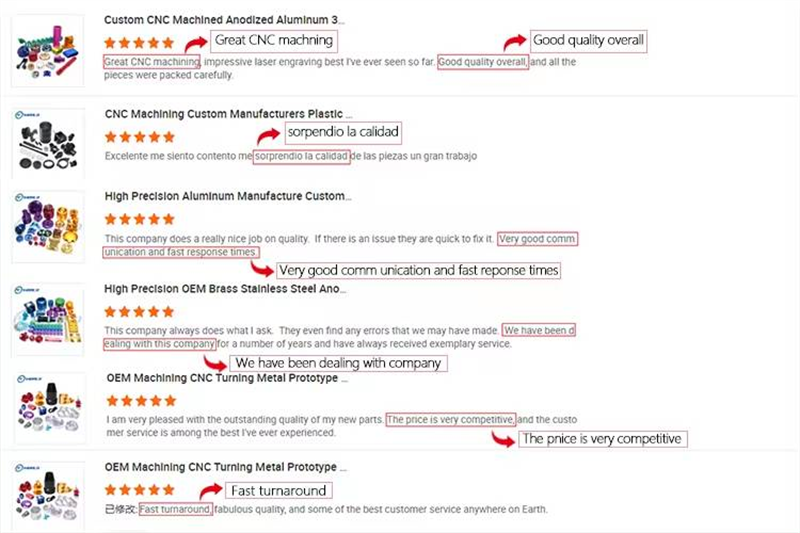

Quality:High End Quality

Certification:ISO9001:2015/ISO13485:2016

MOQ:1Pieces

Product Overview

In today's competitive manufacturing landscape, precision and reliability are critical. Our High-Quality Precision CNC Milling Parts Service is designed to meet the demands of industries requiring exceptional craftsmanship and rapid production. From intricate prototypes to mass-produced components, we provide solutions tailored to your exact specifications.

Benefits of Our High-Quality Precision CNC Milling Parts Service

1.Superior Accuracy

Achieve tolerances as tight as ±0.005mm, ensuring components meet your exact design requirements.

2.Comprehensive Material Options

We specialize in milling materials like aluminum, stainless steel, titanium, brass, and high-performance plastics.

3.Custom Finishes

Enhance durability and aesthetics with anodizing, powder coating, polishing, or sandblasting.

4.Fast Turnaround

Our advanced processes ensure timely delivery, whether you need prototypes or large production runs.

5.Cost-Effective Solutions

Optimize your production costs without sacrificing quality through our efficient processes.

Applications of Precision CNC Milling Parts

Our high-quality CNC milling services cater to a broad range of applications, including:

1.Aerospace Components

Lightweight, high-strength parts like brackets, housings, and structural elements.

2.Automotive Parts

Engine components, suspension systems, and gears designed for performance and reliability.

3.Medical Devices

Precision instruments, implants, and diagnostic equipment meeting strict industry standards.

4.Industrial Machinery

Custom components like rollers, clamps, and gears for seamless machine operations.

5.Electronics Enclosures

Durable housings, heat sinks, and connectors for cutting-edge devices.

Our CNC Milling Process

1.Consultation & Design Review

Share your CAD files or design specifications. Our engineers will provide a thorough analysis and offer recommendations to ensure manufacturability.

2.Material Selection

Choose from a wide range of metals and plastics to suit your project’s needs.

3.Precision Machining

Using advanced CNC milling machines, we deliver highly accurate parts that meet the most demanding requirements.

4.Surface Finishing

Customize your parts with surface treatments that improve functionality and aesthetics.

5.Quality Assurance

Every component undergoes rigorous inspection to ensure compliance with your specifications.

6.Secure Shipping

We securely package and ship your parts worldwide, ensuring they arrive in perfect condition.

When precision and quality matter, our High-Quality Precision CNC Milling Parts Service is the solution. Whether you need custom prototypes or mass production, we are committed to delivering parts that exceed expectations.

Q:What customization options are available for precision milled parts?

A:We offer fully customizable solutions, including:

·Material selection: Wide range of metals and plastics.

·

·Complex geometries: Capable of producing intricate designs.

·Tolerances: Achieving tight tolerances of ±0.01mm or better.

·Surface finishes: Options like anodizing, plating, polishing, and sandblasting.

·Special features: Threads, slots, grooves, or multi-surface machining.

Q:What materials can you work with for custom milled parts?

A:We work with a variety of materials to meet specific application needs, including:

·Metals: Aluminum, stainless steel, titanium, brass, copper, and alloy steels.

·Plastics: ABS, polycarbonate, POM (Delrin), nylon, and more.

·Specialty materials: Magnesium, Inconel, and other high-performance alloys.

Q:What is the maximum size of parts you can mill?

A:We can mill parts with dimensions up to 1,000mm x 500mm x 500mm, depending on the material and design requirements.

Q:Can you create prototypes before mass production?

A:Yes, we offer rapid prototyping services to ensure the design meets all functional and aesthetic requirements before full-scale production.

Q:What is your typical production timeline?

A:Our production timelines depend on complexity and order volume:

·Prototyping: 5-10 business days

·Mass production: 2-4 weeks

Q:Are your milled parts eco-friendly?

A:We are committed to sustainability and offer:

·Eco-friendly materials

·Waste-minimizing production techniques

·Recycling programs for metal scrap

Q:What surface finishes can you provide for milled parts?

A:We offer a range of surface treatments to enhance durability, appearance, and functionality, including:

·Anodizing (clear or colored)

·Electroless nickel plating

·Chrome plating

·Powder coating

·Polishing, sandblasting, or bead blasting

Q:How do you ensure the quality of your milled parts?

A:We implement a rigorous quality control process, including:

·Dimensional inspections: Using advanced measurement tools like CMMs.

·Material verification: Ensuring raw materials meet industry standards.

·Functional testing: For critical performance requirements.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog