Perché il Design del Moulding per Iniezione è Importante?

La competenza di Swords Precision comprende che la qualità è estremamente importante nel materiale utilizzato per il design del moulding per iniezione. Selezionare il materiale appropriato aiuta a garantire che le cose siano fatte correttamente e funzionino in modo appropriato. Successivamente, ci sono i modelli per iniezione — che utilizzano una varietà di materiali per la fabbricazione dei modelli, inclusi metalli e plastiche. Questi materiali sono speciali per la carta: ogni materiale ha le sue capacità segrete e proprietà. Usate ciò che imparate: Ad esempio, alcune plastiche hanno una grande resistenza alla trazione, mentre altre sono più malleabili. Selezionare il materiale appropriato può migliorare significativamente le prestazioni del modello e la qualità del prodotto finale.

Perché i Parametri di Progettazione Sono Fondamentali?

Queste sono regole uniche per i modelli di vaccini. La comprensione è importante perché influenzerà l'efficienza dei modelli, la qualità delle parti e il ciclo di manutenzione dei modelli. Qui a Swords Precision, ci concentriamo su alcuni fattori cruciali nella progettazione del prodotto, come la dimensione degli ingressi, dei runner e quanto spazio ci sarà all'interno del modello da riempire con il plastico. Tutti questi fattori possono influenzare significativamente le prestazioni del modello. Si tratta di parametri di progettazione con cui bisogna essere attenti per ottenere i migliori risultati possibili per i nostri clienti, garantendo che i loro prodotti rispettino gli standard dell'industria.

Utilizzo della Simulazione del Flusso Modellante

Esistono molti strumenti che ci aiutano a migliorare il nostro progetto di stampo iniezione, uno di questi strumenti è la simulazione del flusso dello stampo. Questo ci permette di visualizzare come il plastico scorre attraverso lo stampo. In questo modo possiamo vedere se ci sono eventuali punti critici, ad esempio aree in cui il plastico potrebbe non riempire lo stampo correttamente. Individuando questi problemi a questa fase, possiamo correggerli prima di creare fisicamente lo stampo. Ciò ci risparmia tempo, denaro e sforzo. Swords Precision utilizza la simulazione del flusso dello stampo per consigliare i nostri clienti su progetti ottimali per i loro stampi, risultando in prodotti migliori e in un minor numero di errori durante il processo di produzione.

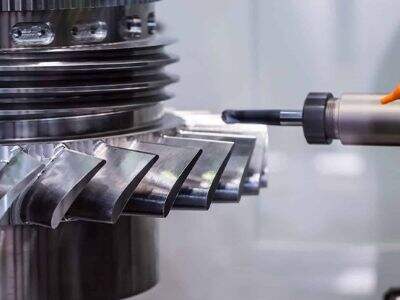

Come prepararsi per stampi robusti

Swords Precision aderisce alle migliori pratiche per costruire moldi solidi in grado di superare le transizioni della produzione. Un buon stampo, quindi, è quello in grado di resistere alle fatiche del processo produttivo, senza deteriorarsi troppo velocemente o essere attaccato dai plasticizzanti sotto la pressione e le temperature utilizzate nel processo di produzione. Consideriamo molteplici aspetti quando progettiamo questi moldi. Ad esempio, se analizziamo il materiale che intendiamo utilizzare, la progettazione delle gate e dei runner, e come pianifichiamo di raffreddare lo stampo. Il raffreddamento è molto essenziale perché consente al plastico di solidificarsi correttamente. Tutte queste migliori pratiche aiuteranno lo stampo a continuare a produrre parti di qualità, e ciò è fondamentale per soddisfare i nostri clienti.

Rendere la produzione efficiente

L'efficienza nella produzione è fondamentale per qualsiasi processo di produzione. Se riusciamo a produrre componenti velocemente e con alta qualità, tutti ne traggono vantaggio.” Come produttore presso Swords Precision, ci impegniamo costantemente per migliorare quei caratteri design chiave per garantire che la produzione possa essere un processo fluido ed efficiente. L'attenzione è focalizzata sul tempo di ciclo — quanto tempo impiega per completare un ciclo di produzione — sulla qualità dei componenti — quanto sono buoni i pezzi — e su quanto bene le macchine vengono utilizzate nel processo. Concentrandosi su questi criteri, i nostri clienti sono assicurati di ricevere un buon valore in componenti di qualità che beneficiano il loro business.

Conclusione

In sintesi, numerosi elementi significativi contribuiscono a realizzare stampi iniezione produttivi. Identificare i materiali corretti, una comprensione dettagliata dei parametri di progettazione, la simulazione del flusso della resina, le migliori pratiche per ottenere stampi più robusti e il massimo dell'efficienza con elementi chiave di progettazione per la produzione sono solo alcuni dei passaggi cruciali. Progetti di stampi iniezione; a Swords Precision ci impegniamo al massimo. Cerchiamo sempre di creare lo stampo migliore affinché il cliente possa svolgere il proprio lavoro in modo affidabile.