Per questo tipo di componenti, l'uso di materiali robusti e macchine speciali è un bisogno assoluto. Il titanio è uno dei migliori materiali che possiamo utilizzare a tal fine. Il titanio è un metallo eccezionale con diverse caratteristiche fantastiche. Significa che è molto resistente e può sopportare punizioni serie prima di cedere. Inoltre, è leggero, quindi non aggiunge peso eccessivo ai prodotti che progettiamo. Il titanio non arrugginisce anche, il che lo fa durare a lungo in ambienti difficili. Swords Precision si specializza nella produzione di componenti in titanio su misura tramite CNC. Utilizzando questo metodo, siamo in grado di progettare e fornire ottimi prodotti che verranno utilizzati in vari settori, inclusi aeronautico, medico e militare.

Macchine CNC per la lavorazione di componenti in titanio

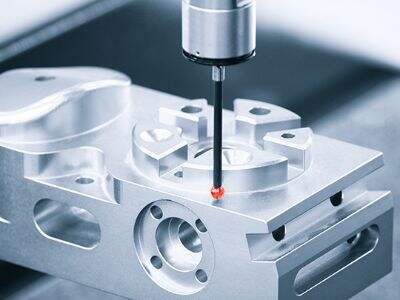

Il processo effettivo di produzione di componenti in titanio è molto intensivo in termini di competenze e lavoro manuale. Questo processo avanzato non può essere ridotto semplicemente all'assemblaggio di determinate parti, ma deve fare affidamento su tecniche e tecnologie speciali. Questi componenti vengono realizzati utilizzando macchine CNC, l'acronimo di Computer Numerical Control. Oggi, le macchine sono avanzate e ci aiutano a creare una parte precisa ogni volta che le eseguiamo. Questa precisione è fondamentale poiché ogni componente deve adattarsi al suo preciso posto. La realizzazione manuale di queste parti renderebbe molto più difficile ottenere i dettagli corretti. Possiamo garantire il funzionamento del componente per il suo scopo previsto grazie alla tecnologia CNC, che garantisce che ogni singolo componente venga prodotto esattamente come progettato.

La Forza e la Durata dei Componenti in Titanio Su Misura

Un altro vantaggio dei componenti in titanio personalizzati di alta qualità è la loro resistenza e durata. Il titanio è duro come chiodi — letteralmente; sia esso calore, freddo o pressione estremi. Ciò significa che le parti che progettiamo possono essere utilizzate in numerosi contesti diversi senza sgretolarsi. L'applicazione della tecnologia CNC ci consente di progettare ciascun componente nella sua forma più resistente e duratura. Questo è fondamentale per lavori che richiedono componenti solidi sui quali si può contare anche nelle peggiori condizioni.

Parti: Personalizzate vs. Prodotte in Serie

Quindi, quando parliamo di produzione di massa, intendiamo che queste parti in titanio vengono create velocemente e con poco riguardo, utilizzando solitamente materiali di qualità inferiore. Il controllo qualità e il processo produttivo sono spesso meno impeccabili, e questo può causare problemi. Per esempio, potrebbero non essere così robusti quanto possibile e potrebbero non essere adatti allo scopo per cui devono essere utilizzati. Voi siete parti personalizzate in titanio con lavorazione meccanica. Ciò significa che utilizziamo i migliori materiali e tecniche per ogni singolo componente. A causa di ciò, i pezzi su misura tendono ad essere più adatti e precisi e si adatteranno meglio allo scopo per cui sono destinati.

Perché le Parti in Titanio Personalizzate Richiedono Macchine CNC?

Qui la lavorazione CNC gioca un ruolo fondamentale nella produzione di parti in titanio di alta qualità. Inoltre, questa tecnologia ci consente di costruire materiali con una precisione di alto livello insolita con i metodi manuali. fornitori di lavorazioni CNC offre la ripetibilità del processo per garantire che tutte le parti individuali vengano realizzate esattamente come progettate con un minimo di errori. Di conseguenza, ci sono meno difetti e si garantisce anche la resistenza e la durata delle parti. A Swords Precision utilizziamo le tecnologie più avanzate componenti di precisione CNC per produrre componenti in titanio su misura per numerosi settori. Siamo addestrati per fornire ai nostri clienti prodotti di qualità al miglior prezzo disponibile.

In sintesi, i vantaggi delle parti in titanio a precisione personalizzate. Sono le più adatte per varie applicazioni e settori industriali. Miriamo a essere i fornitori leader a livello mondiale di componenti in titanio su misura grazie ai nostri processi di produzione all'avanguardia, alla nostra attenzione scrupolosa ai dettagli e al nostro impegno dedicato per la qualità — Swords Precision. Produrremo componenti macchina, sottocomponenti e assemblaggi completi; siano essi per aerei, attrezzature mediche, contratti militari e altro— siamo pronti a realizzarlo! Il nostro impegno rimane quello di produrre i migliori prodotti che soddisferanno i nostri clienti e di fornire il meglio in tutti gli aspetti. E questo impegno per la qualità e il servizio permette ai nostri clienti di stare tranquilli sapendo di utilizzare i migliori componenti possibili per i loro progetti critici.