Bangunan 49, Taman Perindustrian Fumin, Kampung Pinghu, Daerah Longgang

Ahad ditutup

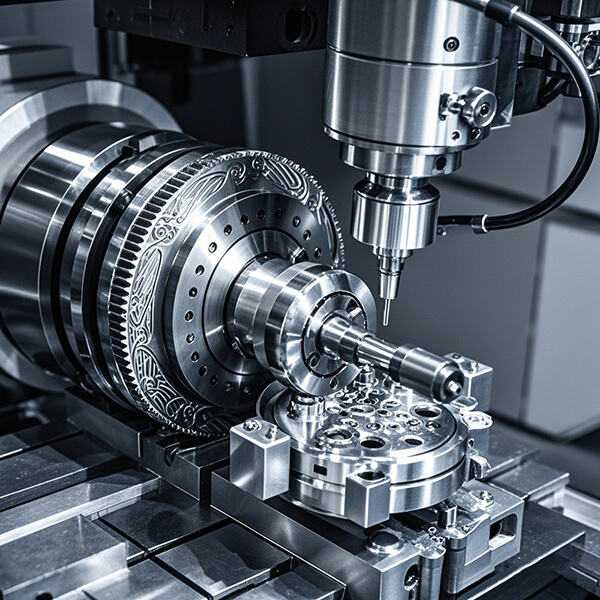

Bahagian CNC aluminium is an industry-specific engineering that assists us in generating machine components with high precision. It runs a computer program that tells the machines how to make these parts. This is performed using a special tool known as a CNC machine (CNC stands for Computer Numerical Control machine). So these machines are quite significant because they bring us very closely toleranced parts that fit well, to operate more efficiently. A company that does this exceptionally well is Swords Precision. They are a CNC Precision Engineering leader that applies modern and innovative solutions to manufacture high-quality components for a wide range of applications.

What is CNC machining? CNC machining is a process in which pre-programmed computer software controls the movement of factory tools and machinery. It is used to 3D print plastic and metal parts and components.

So, what does CNC mean? CNC means Computer Numerical Control. This means we can run computers to operate machines that create parts very accurately. Prior to the advent of computers, people had to control the machines manually. This was a lot harder and took a lot longer. Well, with Komponen mesin CNC, computers pretty much do all of the hard work! It has become possible to fabricate almost every type of machine part you can imagine. One of the companies using this technology is Swords Precision, which creates high-quality parts and components for virtually every type of industry, from automotive and aerospace to toys.

Here are some advantages of CNC Precision Engineering over traditional methods for producing machine components. This process itself is a huge benefit as it speeds things up. Previously, the creation of only one machine part took a long time, sometimes up to days! However, with CNC Precision Engineering, the same part can be manufactured in a few minutes. This saves a significant amount of time and money, particularly when multiple components are produced in one go. For instance, when a workshop needs thousands of parts on-demand, CNC Precision Engineering is there to assist as quickly, efficiently as possible. As an example of a great company that relies on CNC Precision Engineering to deliver quality machine parts on time, they have provided a unique situation in which there is plenty of importance placed on not just quality but also on getting the finished piece quickly.

Not only are swords Precision fast, they are problem solvers who find innovative ways to create exotic machine parts. They use CNC Precision Engineering to manufacture nearly any part their clients require, regardless of the complexity. They sit side-by-side with their customers to get to the heart of what they need. This may involve discussing how big or small the parts are, what shape they are, what they do, etc. Then, after they understand what the customers want, they write a computer program that instructs the CNC machine step by step on how to fabricate the part. Taking the time to select the right machines, makes sure that the quality of the custom part made, is second to none, and perfectly fitted to match the requirements proposed by the appraiser.

In many industries, things are being manufactured in various ways but CNC Precision Engineering is revolutionizing such techniques. This incredible technology allows companies to make parts faster than ever before and more accurately than ever. It enables them to deliver more products in lower time and saves time and money for everyone. The parts they produce are of higher quality, and this makes the finished products even higher quality. For instance, if a company produces toys, it means making sure every toy is safe and well designed. Swords Precision is leading the way against this exhilarating transition; the use of CNC Precision Engineering to produce chiselled nylon machine components for various industries, including the automotive and medical manufacturing.

Swords Precision has high-quality machine parts that they manufacture using a type of technology called precision technology. For example, CNC machines which are computer programmed machines are part of this technology. They use the formliner to create very complex parts; these machines are very accurate and can create parts with very small measurements. Such accuracy is important in numerous sectors, including aerospace, where the perfection of parts helps keep airplanes safe, and in medical devices, where minute mistakes can be extremely serious. Swords Precision utilizes this precision technology to ensure that all of the parts they produce conform to the industry standards for excellence, an important consideration for their clientele.

They have extensive expertise and experience to solve all your concerns. They are highly skilled and have the CNC Precision Engineering to solve your concerns. Custom parts with high precision tolerances: +/-0.01 mm, Special space: +/-0.005 mm.

OEM and ODM services are available The minimum quantity for orders is 1 piece Quotes are given within CNC Precision Engineering Production of samples takes 1 to 3 working days The delivery time for bulk orders is 7 to 14 working days Our monthly production surpasses 300 000

We offer a wide range of production CNC Precision Engineering, including 3-axis and 4-axis up to 6-axis. We offer a range of processing capabilities that include turning, milling, and drilling, grinding and EDM, 3D Printing. We work with many different materials like copper, brass and aluminum steel, stainless, plastics and composites.

CNC Precision Engineering have ISO9001 certificate, ISO14001, ISO45001, medical ISO13485, aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

Hak Cipta © Shenzhen Perfect Precision Products Co., Ltd. Hak Cipta Terpelihara — Polisi Privasi - Blog