Meneroka Teknologi Pengeboran Servo untuk Aplikasi Pengeluaran Ketepatan Tinggi

Nov.27.2024

Takrifkan secara ringkas pemotongan servo dan pembuatan ketepatan, dengan menekankan kepentingannya dalam industri teknologi tinggi hari ini.

Peranan Pembuatan Ketepatan

1.Takrif dan Kepentingan

- ·Takrif pembuatan ketepatan sebagai proses yang berfokus kepada pengeluaran komponen dengan toleransi yang sangat ketat dan kualiti yang konsisten.

- ·Tegaskan aplikasinya dalam industri seperti penerbangan (komponen enjin), peralatan perubatan (implant, alat bedah), dan elektronik (mikrocekap, sensor).

2.Kelebihan Pembuatan Ketepatan

- ·Kualiti Produk yang Dipertingkatkan : Toleransi konsisten membawa kepada prestasi produk yang lebih baik dan keawetan.

- ·Kecekapan Kos : Walaupun kos awal lebih tinggi, pembuatan ketepatan mengurangkan sisa bahan dan kecacatan produk, mengurangkan perbelanjaan jangka panjang.

- ·Kepatuhan Industri : Memenuhi piawaian perindustrian yang ketat untuk keselamatan dan kebolehpercayaan, seperti sijil ISO dan keperluan peraturan.

Aplikasi Pemotongan Servo dan Pengeluaran Presisi

1.Aeroangkasa

- ·Terangkan bagaimana pemotongan servo digunakan untuk mencipta bahagian presisi tinggi seperti bilah enjin, kerangka kapal terbang, dan komponen gear pendaratan.

- ·Sebutkan keperluan bahan ringan tetapi tahan lama seperti titan dan kumpulan aluminium, yang memerlukan pemotongan presisi.

2.Peranti perubatan

- ·Tegaskan bagaimana pengeluaran presisi memastikan pengeluaran alat bedah, prostetik, dan implan dengan piawaian yang teliti.

- ·Bincangkan peranan pemotongan servo dalam mencipta bahagian perubatan bentuk kompleks dan sesuai biokompatibiliti.

3.Automotif

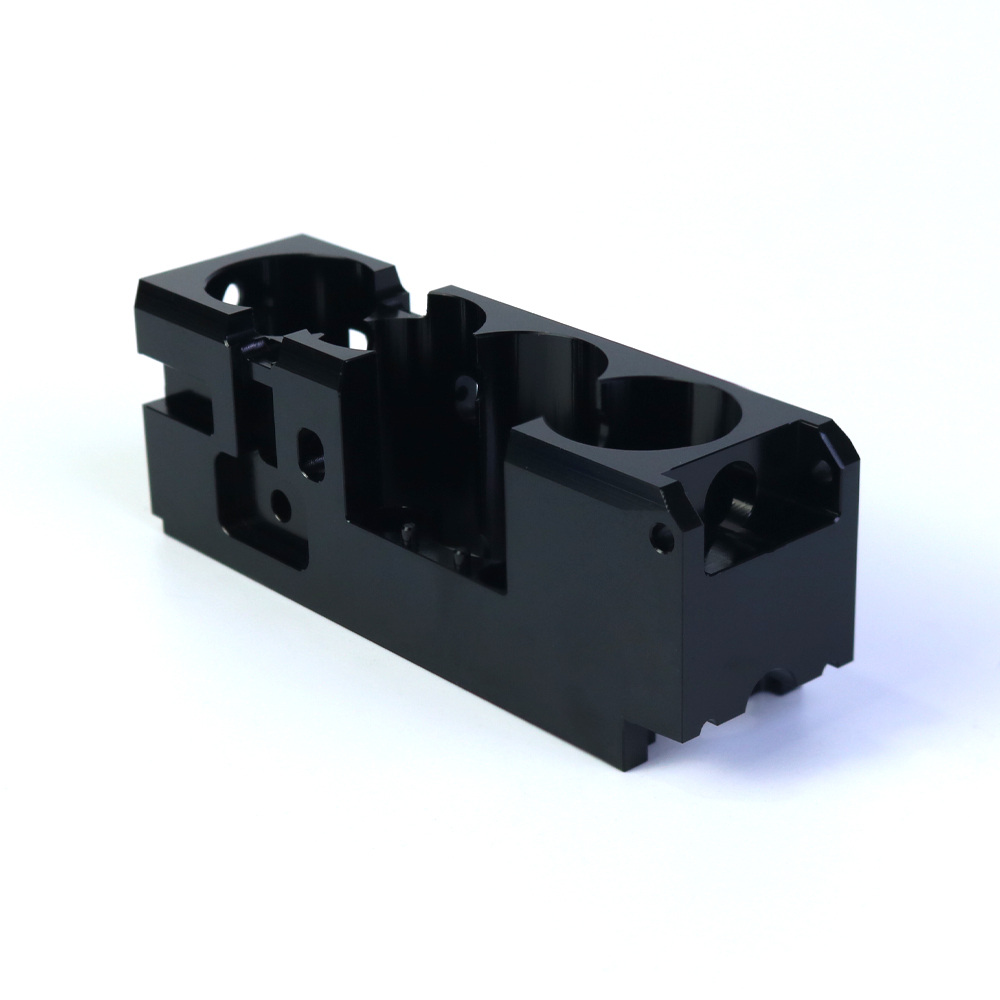

- ·Huraikan aplikasi seperti komponen enjin, sistem gear, dan penutup bateri EV, yang menguntungkan daripada toleransi ketat dan pemotongan presisi.

- ·Sentuh tentang bagaimana pemotongan servo menyumbang kepada pembangunan bahagian ringan, kekuatan tinggi untuk kenderaan elektrik (EV).

4.Elektronik

- ·Jelajahi bagaimana penggilingan servo dan pembuatan dengan kejituan adalah elemen penting dalam menghasilkan mikro-komponen, penyerap haba, dan wafer semikonduktor untuk elektronik canggih.

Kemajuan Teknologi dalam Penggilingan Servo dan Pembuatan dengan Kejituan

1.Integrasi dengan AI dan pembelajaran mesin

- ·Bincangkan bagaimana sistem CNC bertenaga AI menggunakan analisis data untuk mengoptimumkan proses penggilingan servo, meningkatkan kecekapan dan mengurangkan masa henti.

2.Kilang Pintar dan Automasi

- ·Sebutkan peranan Industri 4.0 dalam mengintegrasikan sistem penggilingan servo ke dalam lini pengeluaran automatik, membolehkan pemantauan secara real-time dan pemesinan adaptif.

3.Bahan dan Alat Terkini

- ·Tegaskan inovasi dalam alat pemotong (contohnya, alat berlapis berlian) dan bahan (contohnya, superaloi, komposit) yang boleh ditangani oleh penggilingan servo dengan kejituan.

Cabaran dan Penyelesaian

1.Pelaburan awal yang tinggi

- ·Kenalpasti kos melaksanakan teknologi penggilingan servo dan sistem CNC terkini.

- ·Cadangkan penyelesaian seperti subsidi kerajaan, ROI jangka panjang, dan kemajuan dalam sistem servo yang lebih terjangkau.

2.Pasukan Kerja Berketerampilan

- ·Bincangkan keperluan operator yang mahir dalam pemrograman CNC dan penyelenggaraan sistem servo.

- ·Cadangkan penyelesaian seperti program latihan dan kemitraan dengan institusi pendidikan.

Trend Masa Depan dalam Pengilangan Servo dan Pengeluaran Ketepatan

1.## Miniaturisasi

- ·Kaji permintaan yang meningkat untuk komponen lebih kecil dan tepat dalam industri seperti mikroelektronik dan nanoteknologi perubatan.

2.Kelestarian

- ·Tegaskan bagaimana pengeluaran ketepatan dan sistem servo mengurangkan buangan dan penggunaan tenaga, selaras dengan matlamat pengeluaran hijau.

3.Teknologi Pembuatan Hibrid

- ·Sebutkan bagaimana penggabungan pengilangan servo dengan pengeluaran tambah (cetakan 3D) menawarkan fleksibiliti dan ketepatan dalam menghasilkan cebisan kompleks.