Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Zondag Gesloten

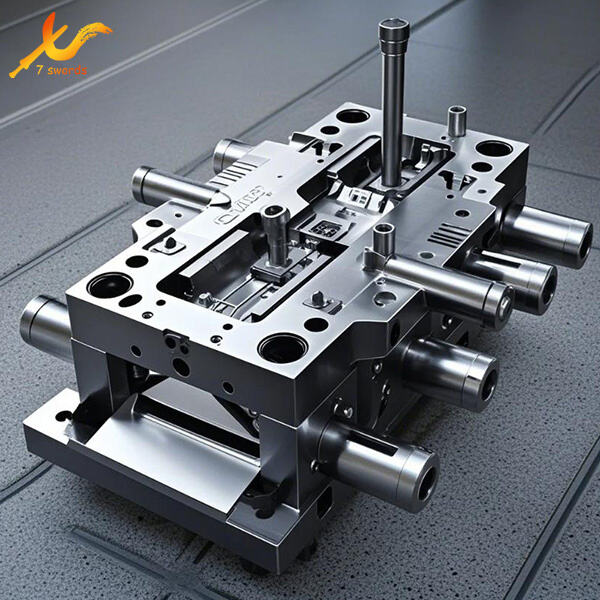

We zijn allemaal bekend met het proces vanKunststof spuitgietendat een van de belangrijkste processen is in de productie van een breed scala aan plastic onderdelen en producten die we in ons dagelijks leven gebruiken. Elk proces begint met een bepaald type materiaal zoals plastic resin. Eerst wordt de resin verhit tot een dikke vloeistofstaat. Dit is een bijzonder belangrijke stap voor het smelten, omdat de resin alleen kan worden geïnjecteerd wanneer hij gesmolten is, d.w.z. De vorm is een tweedeel ontwerp dat precies samenpast om een vorm te creëren.

Daarna, wanneer de gesmolten plastic wordt ingebracht in de vorm, wordt het toegestaan om af te koelen. Het afkoelsproces is cruciaal omdat het de plastic laat verstijven in de vorm van de mouw. Nadat de plastic is afgekoeld, vastgestold en de twee vormstukken zijn geopend, kan het nieuwe plastic onderdeel worden verwijderd. Dit kan meerdere keren worden herhaald om tonnen identieke plastic stukken te produceren, dus in termen van productie is het zeer efficiënt.

De keuze van eenCNC plastic onderdelenis cruciaal voor het waarborgen van de kwaliteit van de plastic onderdelen. Het selecteren van de juiste grondstoffen is de eerste stap in dit proces. Sommige zijn robuuster en duurzamer, wat betekent dat ze veel gebruik kunnen verdragen zonder te breken. Andere materialen zijn flexibeler - ze kunnen buigen zonder te breken. De keuze van het materiaal zal moeten berusten op wat je van plan bent te gebruiken voor het plastic onderdeel.

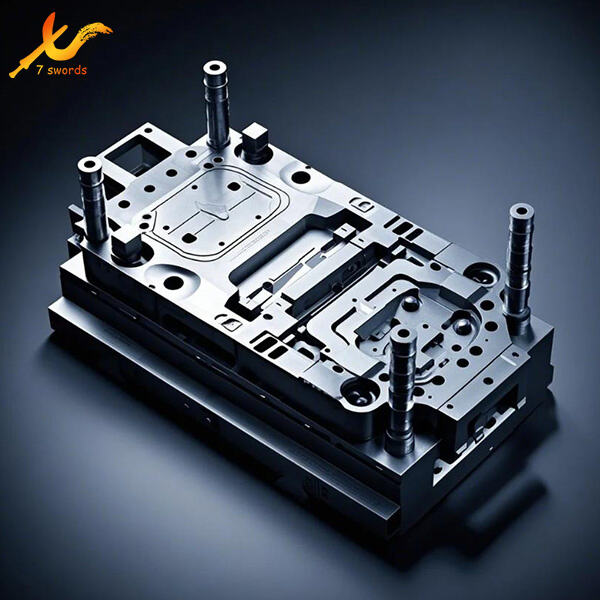

Dan moet je een goed ontwerp kiezen voor de vorm. Een goed ontworpen vorm zorgt ervoor dat het gesmolten plastic correct in deze vorm wordt geïnjecteerd en dat het eindproduct gemakkelijk uit de vorm kan worden verwijderd nadat het is afgekoeld. Een goed ontworpen oplossing voorkomt problemen en verbetert de kwaliteit van het eindproduct. Uiteindelijk is het cruciaal om een bedrijf te hebben dat zich specialiseert in de productie van injectievormen, zoals Swords Precision, om je onderdelen te laten produceren. Een ervaren bedrijf heeft de benodigde gereedschappen en kennis om kwalitatieve vormen te creëren.

Het is zeer belangrijk bij de productie van kunststofonderdelen dat dit op een kostenefficiënte manier wordt gedaan. Hot-runner vormen zijn een voorbeeld van hoe dit kan worden bereikt. Deze vormen bijdragen ook aan de vermindering van afval omdat ze het kunststof warm houden en klaar voor injectie, op deze manier gaan er geen restanten onbenut. Ze kunnen ook de productieprocessen versnellen, waardoor onderdelen sneller kunnen worden gemaakt.

Daarnaast helpt een hoge-snelheids kunststof injectie-machines ook bij het verhogen van de efficiëntie. Hierdoor zijn ze nu in staat om kunststof onderdelen veel sneller te produceren dan voorheen, en significant de tijd te verminderen die nodig is om die onderdelen te produceren vergeleken met machines uit het verleden. Dit stelt bedrijven in staat om grote contracten sneller te voltooien, wat heel gunstig is voor de zaak.

Een ander, lastiger probleem is 'flash', dat optreedt wanneer de kunststof tijdens de injectie uit de vorm loopt. Dit resulteert in kleine uitlopers van overbodige kunststof onder de randen van het onderdeel, wat ongewenst is. Zinkmerken zijn kleine deuken die kunnen ontstaan op het oppervlak van een kunststof onderdeel wanneer het te snel afkoelt. Deze deuken kunnen de uiterlijke aanblik en kwaliteit van het eindproduct beïnvloeden.

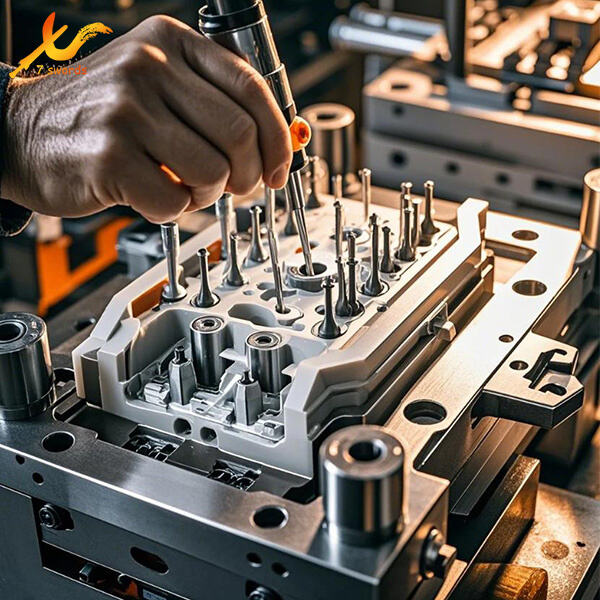

Ons team van ervaren ingenieurs is altijd beschikbaar, klaar om antwoord te geven op uw vragen over plastic injectiemotoren. Ze hebben de expertise en kennis om al uw zorgen aan te pakken. Aangepaste hoogprecisiedelen Tolerantie: +/-0.01 mm, Speciale ruimte: +/-0.005 mm.

We hebben de ISO9001 certificatie, ISO14001, plastic injectiemodellen, medisch ISO13485, luchtvaart AS9100, Automobiel IATF16949, we kunnen mechanische onderdelen, auto-onderdelen, elektronica-onderdelen, lucht- en ruimtevaartonderdelen, medische apparaatonderdelen, communicatieapparatuuronderdelen, nieuwe energie-onderdelen, bouw- en huishoudelijke producten onderdelen produceren.

We bieden OEM- en plastic injectiemodelservices aan. De minimale bestelhoeveelheid is 1 stuk. Offertes worden binnen 3 uur verstrekt. Productie van monsters duurt 1 tot 3 werkdagen. Levering voor grote hoeveelheden is 7-14 dagen. Onze maandelijkse productie overschrijdt 300 000.

Onze productiemiddelen omvatten: 3-as (plastic injectiemodellen), 5-as en ook 6-as machines. Onze bewerkingsmogelijkheden omvatten draaien, frezen, boren, slijpen, EDM, 3D-printen en meer. We werken met veel verschillende materialen, waaronder aluminium, messing en koper roestvast staal kunststoffen, composieten en.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved —Privacybeleid—Blog