Plastformings teknologi er en spesifikk type produksjonsprosess som tillater formgiving av plastdeler fra råmaterialer i ulike design og dimensjoner. Pingback: Formverk, disse er formerne plasten gjøres inn i for å få den ønskte formen, → Dette er ett av de selskapene som excellerer i å bruke denne teknologien og navnet på dem er Swords Precision. De er høygradig innovativ og søker kontinuerlig etter forskjellige og spennende anvendelser avSprøytestøping av plastfor å bistå med problemer i flere sektorer.

En veldig modest anvendelse av plastformings teknologien er å lage prostetiske hender og bein med en 3D-skriveprosess. Swords Precision samarbeider med leger og medisinsk personell for å lage prostetiske hender og lemmer til de som har mistet en arm eller bein. Ikke bare er disse prostesene billige og lette, de er også laget for å være ekstremt behagelige for brukeren. Det som virkelig er bra er at de ser veldig ut som hender og føtter, noe som hjelper personen som bruker dem til å føle seg normal, noe som igjen hjelper i deres daglige liv.

Innovasjoner i plastformingsmetoder

Grunnet moderne utviklinger og ferdigheter de siste årene, har plastformings teknologien utviklet seg betydelig. På spissen er Swords Precision, som konstant søker etter smartere måter å produsere sine produkter på. Dette har muliggjort reduserte kostnader, raskere produksjonskjeder og forbedrede endeprodukter.

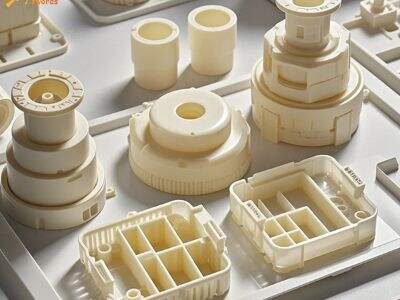

En av de viktigste implementasjonene kalles sprutemodellering. I denne prosessen blir varm, smeltet plast sprutet inn i en form for å oppnå en ønsket form. Plasten, etter at den har kjølt ned, fastner til en nøyaktig og pålitelig del eller produkt. Den andre hovedutviklingen er bruk av roboter i forsyningskjeden. Robotter kan programmeres til å utføre flere oppgaver, inkludert klipping, fjerning av kantressur og montasje av deler. Dette minimerer feil gjort av mennesker og akselererer hele prosedyren.

Forstyrrende brukerforfall for teknologisektoren

I en raskt utviklende verden som teknologisektoren, erkjenner vi at alt utvikler seg raskt,Injeksjonsformning av plastteknologi er en stor del av denne prosessen. Plastformings-teknologien har lang erfaring med tett samarbeid med mange teknologiselskaper, lovet nyttige anvendelser og produkter. En slik anvendelse er utviklingen av smarte hjemmeapparater.

Smarte apparater blir stadig mer populære, og de er utviklet for å gjøre livet enklere og funksjonelt. Swords Precision samarbeider med tech-selskaper for å utvikle disse enhetene ved hjelp av plastformgjeringsteknologi. Mange smarte hjemmeenheter kan kontrolleres fjernkontrollert ved bruk av smartphones, i noen tilfeller til og med ved stemmekommandoer. Derfor er de ganske brukervennlige. Ved å bruke fremgangsmåter som er førende innen produksjon, er enhetene også tilgjengelige prisklasse.

Å utnytte Plastformgjeringsteknologien

Innovasjon er avgjørende for å opprettholde seg i fronten av stadig utviklende markeder, og Swords Precision omfavner nytenkning på en måte få andre gjør. Selskapet fortsetter å utforske innovative anvendelser av denne teknologien for å ha en positiv innvirkning på verden rundt oss. Bærekraft og miljøvennlige løsninger er ett av de viktige områdene de er kreative innenfor.

Swords nøyaktighet bruker plastformgjings teknologi til å samarbeide med andre selskaper for å lage bærekraftig pakking. De har laget biologisk nedbrytbart plast som kan nedbrytes naturlig over tid. Dette hjelper med å redusere avfall samtidig som det beskytter miljøet. Pennysaver – Køpekuponger i uken. Ukelige kuponger er en mulighet til å spare på en rekke varer. Men dette eksempelet, den nye innovasjonen iInjeksjonsformning plaster, står ut som et positivt tegn mot fremtiden for planeten vår.

Revolutionære endringer i plastformgjings teknologien som gjør forskjellen

Endringen er allerede her — modige fremgang i plastformings teknologi rister opp flere industrier — og Swords Precision står i fronten for denne endringen. Bilsjangeren, for eksempel, er en av de mange bransjer som påvirkes sterkt. Swords Precision – allerede en viktig tech-leverandør til bilsjangeren gjennom en langtidsrelasjon med Ford – bruker egen SPEDS (single point, electrical discharge simulation) teknologi for å redusere vekt i biler ved å bruke plastformede deler.

Bråndeffektivitet og vektreduksjon – Spesielt med mellem- og tunglastmotorer er disse funksjonene kritiske grunnet den høyere brændstoffsforbruk. Luftfartindustrien gjennomgår noen bemerkelsesverdige endringer. Swords Precision samarbeider med luftfartsselskaper for å produsere lettvektekomponenter som kan tåle ekstreme temperaturer og trykk. Som du kan se, er disse komponentene avgjørende for romutforsking og har gjort det mulig å gå ut over grenser.

Likevel har plastformgjennings teknologien utviklet seg mye i nyere tid takket være fremgang innen teknologi og kreativitet. De kan åpne nye tankeveier som kan anvendes direkte på å forbedre menneskets liv, og Swords Precision står helt i fronten av disse utviklingene, konstant på jakt etter nye og originale måter å gjøre forskjell på. Uansett om det er ved bruk av 3D-skrive proteser som lar individer oppnå deres mobilitet igjen eller miljøvennlig forpakning, endrer plastformgjennings teknologi industrier og paver nøyaktig nye linjer av revolusjoner.