Budynek 49, Fumin Industrial Park, wioska Pinghu, dystrykt Longgang

Niedziela zamknięta

We use metal to make a variety of objects because it is a very strong and durable material. Metal is in things you see and use every day, from cars to tools to even buildings. This is used to create parts in a special process called metal fabrication. We must follow this process; otherwise, we will not be able to produce the things we need to continue living. Metal fabrication is a very crafty process, and it should be done in the right manner so that we get durable products from the items we use.

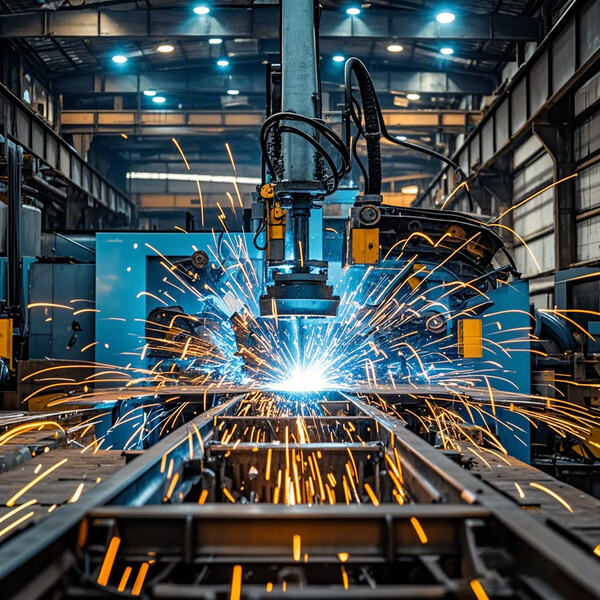

Working with metal products is a complex process and entails a number of different operations being carried out. Once the metal is in stock, it must be cut to size and shape. This is done with special tools such as saws, shears, or lasers. Once the metal is cut, it can be bent and formed into various shapes. This is typically done using machines such as press brakes or rollers that exert force on the metal. The final step, once the metal pieces have been shaped, is to join them together. This is achieved through a process called welding, using heat or pressure to fuse different pieces of metal. The final step is finishing the metal, which you can do by polishing it, or painting it to achieve a nice appearance and protection.

Metal fabrication high quality often comprises a prevent- refund policy. It does make sure that every single item that comes out of the factory is safe and functional. For example, imagine a metal part that has been designed, manufactured, but not made correctly; this metallurgical defect could cause a breakage or failure when put to work, which is dangerous.” A reputable metal fabrication firm, Swords Precision, prides itself in having strict quality control procedures. They verify their work carefully, guaranteeing the safety and reliability of each of the products that they create. It is this attention to detail that makes their products reliable and authoritative.

New technology is continuously evolving and improving the metal fabrication industry. One game-changing technology is 3D printing, which enables the speedy and precise production of metal components. The appeal of this technology is that it simplifies the design and production process for these complicated forms that tend to be difficult to construct otherwise. The other major change is the increase in the use of robots for tasks such as welding and assembly. They can work perfectly and ensures faster manufacturing. Get your facts right, swords precision knows the dynamic technology. Metalworkers invest in these tools so that they can improve their metal fabrication processes and always produce better-quality products.

Metal fabrication is involved in various fields and industries. Take the automotive sector, for instance, metal is vital in the production of car components including frames and engines. Metal is the face of the sticky frame of buildings that keep the building healthy and strong. Moreover, the medical industry uses metal in the manufacture of key medical devices and instruments. May or may not be familiar with the company in the following passage. They also collaborate with the clients to ensure the products align with their needs.

Metal fabrication is a process that has been utilized for thousands of years. “We at Swords Precision are proud to carry on this age-old tradition. They appreciate the skill and craftsmanship of metalwork and know how critical it is to maintain a high standard. This is the reason their metal products are unique, high in quality, and suitable for clients' needs. Combining old and new to create items that are distinctly functional and well-crafted.

We have ISO9001 certificate, ISO14001, ISO45001, medical Metal fabrication industry aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

Our team of experienced engineers is always available, ready to respond Metal fabrication industry to your inquiries. They have the expertise and knowledge to address all your concerns. Custom high precision partsTolerance: +/-0.01 mm, Special space: +/-0.005 mm.

OEM and ODM services are offered Metal fabrication industry quantity is 1 piece We provide quotations within three hours Sample production requires 1 to 3 days Bulk delivery can take 7 to 14 days Our monthly production capacity exceeds 300 000 pieces

We have a range of Metal fabrication industry equipment, ranging from 3-axis and 4-axis up to 6-axis. We offer a variety of processing capabilities that include turning, milling and drilling, grinding as well as EDM and 3D Printing. We deal with a wide range of materials such as aluminum, brass, copper steel, stainless steel, plastics, composites, crafting parts fitting to any industrial requirement.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. Wszelkie prawa zastrzeżone — Polityka Prywatności - Blog