Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Niedziela Zamknięte

Czy kiedykolwiek zastanawiałeś się, jak są robione Twoje ulubione zabawki, przydatne narzędzia kuchenne i niezbędne części samochodowe? Wtryskowe formowanie plastiku jest popularną metodą tworzenia przedmiotów tego typu. Jest to interesujące, ponieważ wykorzystuje stopiony plastik do tworzenia kształtów zgodnie ze specyfikacjami. Oto jak to działa: Nagrzewają plastik do momentu, aż się topi, a następnie wpychają ten stopiony plastik do formy. Następnie, po umieszczeniu go w formie, ochładza się i twardeje, co prowadzi do ostatecznego produktu, który widzisz i używasz codziennie.

Wtryskowe formowanie plastiku jest jedną z najbardziej preferowanych metod produkcji produktów przez firmy. Główną przewagą jest to, że proces daje bardzo dokładne i precyzyjne kształty. To zapewnia, że produkt ma takie same wymiary i detale, jakie projektanci zamierzyli.

Więc, kolejną cudowną rzeczą w temacie wtryskowanie plastiku jest to, że jest to szybki proces produkcyjny na dużą skalę. Jego szybkość pozwala firmom na wyprodukowanie wielu produktów w krótkim czasie. Jest to szczególnie pożądane, gdy określone produkty są w dużej liczbie wymagane.

Wtryskowe formowanie plastiku umożliwia również produkcję szerokiej gamy kształtów i rozmiarów. Firma może potrzebować małych elementów dla zabawek lub dużych elementów dla mebli — ta technologia może być używana do wszelkiego rodzaju obiektów.

Na przykład, jeśli musi wytrzymać wysokie temperatury, używa się plastyku nazwanego nylonem, który jest cierpliwym na temperatura. Jednakże, jeśli produkt musi być nadzwyczaj silny, lepszym wyborem będzie polikarbonat (jeden z tzw. plastików). Znajomość rodzajów plastików pozwala dokonać najlepszego wyboru dla dowolnego danego produktu.

Użyj odpowiedniego plastiku: Wybór właściwego plastiku dla produkowanego produktu jest kluczowy. Nadanie mu odpowiednich właściwości zapewni, że gotowy produkt wytrzyma wszystko, z czym się zmierzy nawet w najtrudniejszych warunkach.

Współpracuj z dobrą firmą – Rzeczywiście, powinieneś współpracować z dobrą firmą zajmującą się wtryskowaniem plastików. Na przykład firma Swords Precision to przedsiębiorstwo z wieloletnim doświadczeniem w tym sektorze. Posiadają wiedzę i umiejętności potrzebne do zapewnienia sukcesu w produkcji produktów wysokiej jakości.

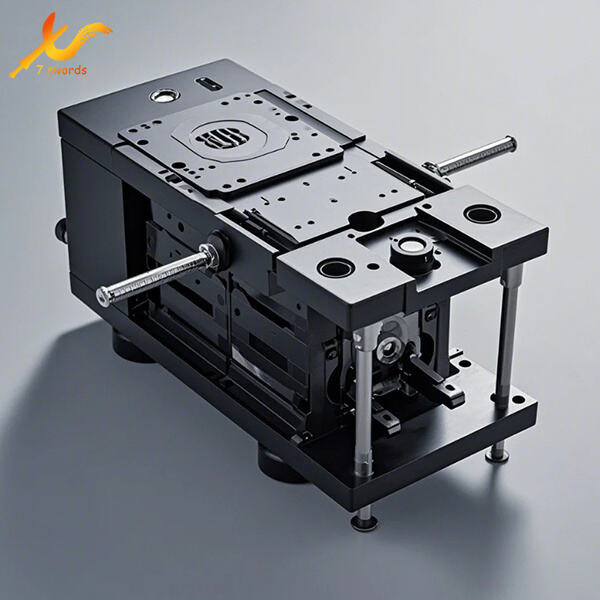

Nasze wyposażenie produkcyjne obejmuje maszyny 3-osiowe (4-osiowe), 5-osiowe, aż do 6-osiowych. Dysponujemy szerokim zakresem możliwości przetwarzania, w tym obróbką tokarską, frezarką, szlifówką, wierceniem oraz wtryskowym formowaniem plastiku, drukowaniem 3D. Mogę pracować z różnymi materiałami, w tym miedzią, aluminium, mosiądzem i stalą nierdzewną, plastikami, kompozytami oraz tworzyć elementy spełniające wszelkie potrzeby przemysłowe.

Ofiarowujemy usługi OEM i ODM. Minimalna ilość zamówienia wynosi 1 sztukę. Oferty są wysyłane w ciągu trzech godzin. Produkcja próbek wymaga od 1 do 3 dni. Dostawy masowe mogą zająć od 7 do produkcji wykorzystującej formowanie plastików przez wtrysk. Nasza miesięczna produkcja przekracza 300 000.

Posiadamy certyfikaty ISO9001, ISO14001, ISO45001, formowanie plastików przez wtrysk ISO13485, lotnictwa AS9100, samochody IATF16949. Możemy produkować części mechaniczne, samochodowe, elektroniczne, lotnicze, medyczne, części urządzeń komunikacyjnych, elementy nowych źródeł energii oraz budowlane i produkty użytkowe.

Nasz zespół doświadczonych inżynierów jest zawsze dostępny, gotowy na odpowiedź w zakresie formowania plastików przez wtrysk na Twoje zapytania. Posiadają oni wiedzę i kompetencje niezbędne do rozwiązania wszystkich Twoich problemów. Niestandardowe części o wysokiej precyzji. Tolerancja: +/-0.01 mm, Przestrzeń specjalna: +/-0.005 mm.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Polityka prywatności—Blog