Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Discover unmatched precision and reliability with our plastic injection molding services at 7 Swords. Specializing in custom plastic parts, we leverage advanced technology and expertise to deliver high-quality components tailored to your exact specifications.

Precision Plastic Injection Molding Services

Welcome to 7 Swords, your premier destination for precision plastic injection molding. We specialize in delivering top-quality, custom plastic parts that meet your exact specifications. Whether you need prototypes or high-volume production, our state-of-the-art facilities and expert team ensure exceptional results every time.

Why Choose Plastic Injection Molding?

Plastic injection molding offers unparalleled versatility and efficiency in manufacturing plastic parts. It allows for intricate geometries, consistent part quality, and cost-effective production of complex shapes. This makes it ideal for a wide range of industries, from automotive and electronics to medical devices and consumer goods.

Our Plastic Injection Molding Capabilities

At 7 Swords, we leverage advanced technology and years of expertise to provide comprehensive plastic injection molding services:

1.Material Selection: We work with a variety of engineering-grade plastics, including ABS, PC, nylon, and more, to meet your specific application requirements.

2.Custom Tooling: Our in-house tooling capabilities ensure precise molds tailored to your designs, optimizing part quality and production efficiency.

3.Process Control: We employ robust process controls and quality assurance measures to maintain consistency and adhere to tight tolerances.

4.Prototype to Production: Whether you need a few prototypes for testing or large-scale production runs, we scale our services to meet your needs without compromising on quality.

Industries We Serve

Our plastic injection molding expertise caters to diverse industries, including:

1.Automotive: Interior components, housings, and trim parts.

2.Electronics: Enclosures, connectors, and consumer electronics parts.

3.Medical: Disposable medical devices, housings, and surgical instruments.

4.Consumer Goods: Household appliances, packaging components, and more.

Why Partner with 7 Swords?

Choosing 7 Swords for your plastic injection molding needs ensures:

1.Technical Expertise: Our skilled engineers and technicians bring years of experience and industry knowledge to each project.

2.Quality Assurance: We uphold strict quality standards and conduct thorough inspections to deliver parts that meet your specifications.

3.Cost Efficiency: By optimizing processes and minimizing waste, we offer competitive pricing without compromising on quality.

4.Customer Focus: We prioritize clear communication, responsiveness, and on-time delivery to exceed your expectations.

Contact Us Today

Ready to start your plastic injection molding project with confidence? Contact 7 Swords to discuss your requirements and discover how we can turn your concepts into reality. Trust us to deliver precision, quality, and reliability in every plastic part we manufacture.

FAQ

1. Are you a manufacturer or a trading company?

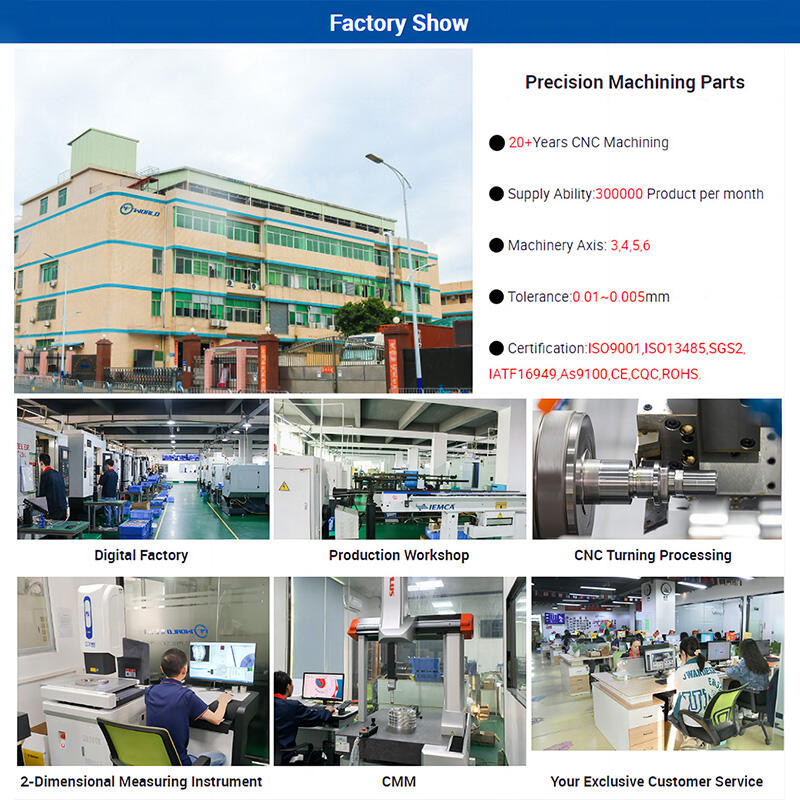

We are a factory located in Shenzhen, China, with 20 years of rich experience,

covering 6000 square meters. Complete facilities, including 3D quality inspection equipment, ERP system and 40 machines. If necessary, we can provide you with material certificates, sample quality inspection and other reports.

2. How to get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...), including quality, delivery date, materials, quality, quantity, surface treatment and other information.

3. Can I get a quotation without drawings?

Can your engineering team draw for my creativity? Of course, we are also glad to receive your samples, pictures or detailed size drafts for accurate quotation.

4. Can you provide samples before mass production?

Of course, the sample fee is necessary. If possible, it will be returned during mass production.

5. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the batch production lasts for 3-4 weeks.

6. How do you control quality?

(1) Material Inspection - Check material surfaces and approximate dimensions.

(2) First inspection of production - ensure

critical dimensions in mass production.

(3) Sampling inspection - check the quality before delivery to the warehouse.

(4) Preshipment inspection - 100% inspection by QC assistant before shipment.

7. After sales service team

If you have any problems after receiving the product, you can provide feedback through voice call, video conference, email, etc. within one month. Our team will provide you with solutions within a week.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog