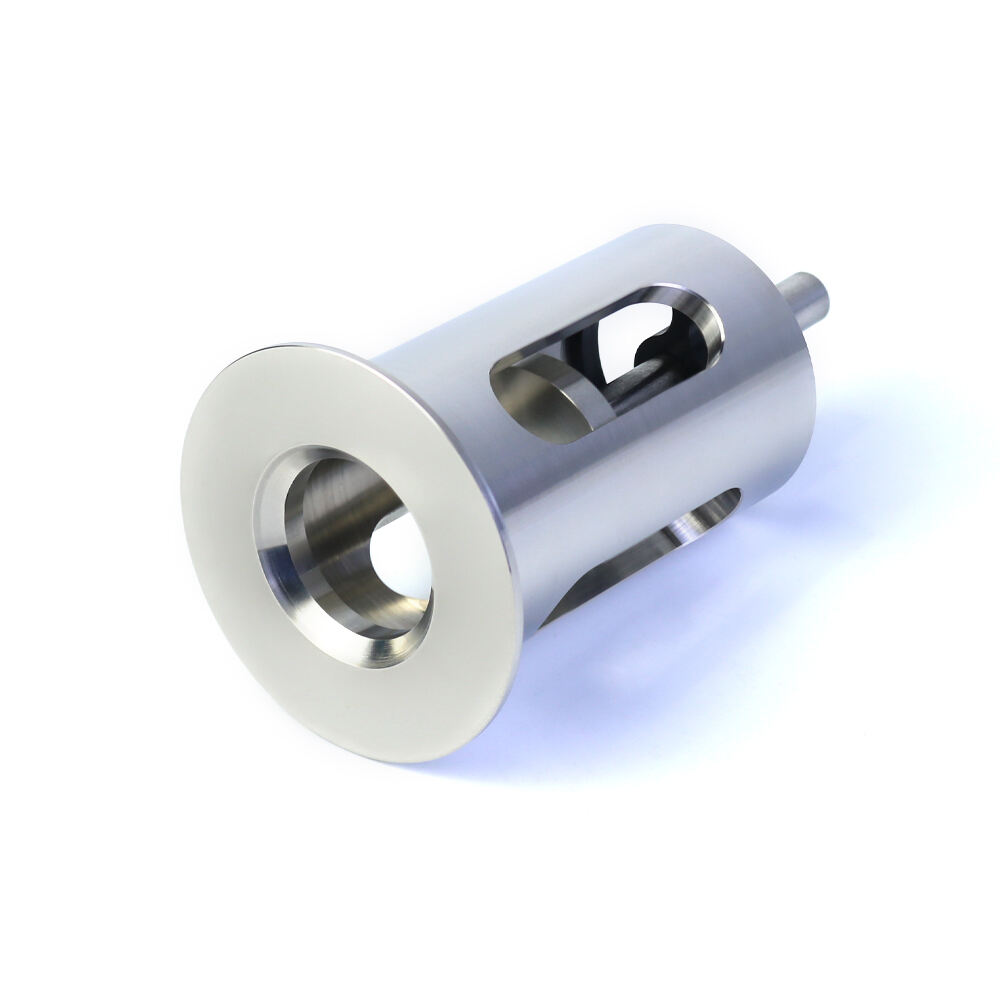

Precision CNC Machining for Auto Parts

The automotive industry is undergoing a transformative shift, driven by advancements in precision CNC (Computer Numerical Control) machining. This technology is revolutionizing the production of automotive components, enhancing efficiency, precision, and flexibility. As the demand for high-quality, customized, and sustainable auto parts grows, CNC machining is emerging as a key driver of innovation in the sector.

Key Components in Automotive CNC Machining

CNC machining plays a crucial role in manufacturing various automotive components, each requiring high precision and reliability:

1. Engine Components: CNC machines are essential for producing engine parts such as cylinder heads, engine blocks, pistons, and crankshafts. These components demand tight tolerances and complex geometries to ensure optimal performance and durability.

2. Transmission Parts: Gear shafts, transmission housings, and clutch components are critical for smooth and reliable vehicle operation. CNC machining ensures the high accuracy and consistency needed for these parts.

3. Body and Chassis Components: CNC technology is used to fabricate body panels, frame parts, and suspension components. The precision of CNC machining ensures uniformity and structural integrity, meeting safety and performance standards.

4. Custom and Aftermarket Parts: CNC machining enables the production of custom and aftermarket components with unparalleled flexibility. This includes interior trim pieces, performance upgrades, and specialized accessories, allowing manufacturers to quickly adapt to customer demands.

Advancements in CNC Machining for Automotive Manufacturing

Recent advancements in CNC machining are further enhancing its capabilities in the automotive industry:

· AI Integration: Artificial Intelligence (AI) is revolutionizing CNC machining by enabling real-time process optimization, predictive maintenance, and adaptive algorithms. AI-driven systems can anticipate maintenance needs, reduce downtime, and improve overall efficiency.

· Automation and Robotics: The integration of robotics with CNC machines is streamlining production lines. Advanced robotic arms equipped with sensors can handle loading, unloading, and assembly tasks, creating fully autonomous systems that enhance productivity.

· Hybrid Manufacturing: The combination of CNC machining with additive manufacturing (3D printing) is unlocking new possibilities. This hybrid approach allows for the creation of complex components with reduced material waste and improved efficiency.

· Sustainable Practices: CNC machining is increasingly adopting eco-friendly solutions, such as energy-efficient designs, recyclable materials, and green lubricants. Innovations like dry machining and closed-loop coolant systems are minimizing waste and environmental impact.

· Enhanced CAM Software: Modern Computer-Aided Manufacturing (CAM) software now includes advanced simulation features that allow machinists to simulate the entire machining process before production. This reduces errors, optimizes tool paths, and ensures high-quality outcomes.

Future Outlook

As the automotive industry continues to evolve, CNC machining will remain at the forefront of innovation. The rise of electric vehicles (EVs) and advanced materials like lightweight composites is driving the need for even more precise and efficient manufacturing processes. CNC machining will play a critical role in producing the next generation of automotive components, from high-density batteries to advanced powertrain systems.

Precision CNC machining is transforming the automotive industry by delivering unparalleled precision, efficiency, and flexibility. With advancements in AI, automation, and sustainable practices, CNC machining is poised to meet the growing demands of modern automotive manufacturing. As the industry embraces these innovations, the future of automotive production looks brighter and more sustainable than ever.