Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

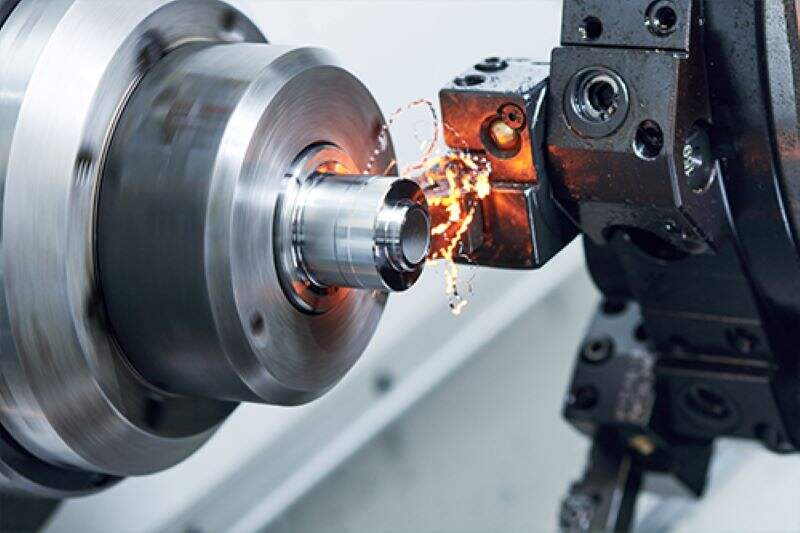

CNC machining services for stainless steel parts. Specializing in high-quality manufacturing for diverse industries, we ensure exacting standards in every component. From intricate prototypes to large-scale production, trust our expertise to deliver durability and performance. Contact us today to discuss your stainless steel machining needs and streamline your production process effortlessly.

Professional Knowledge of Precision Machined Stainless Steel Parts

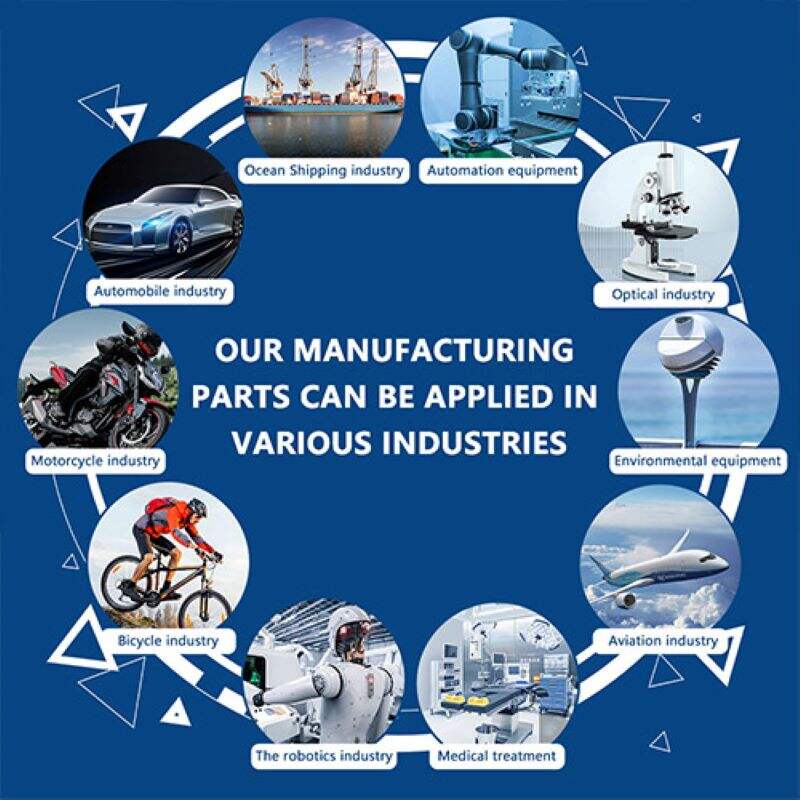

Precision machined stainless steel parts play a crucial role in various industries, from automotive and aerospace to medical and consumer electronics. Their importance lies in their high durability, corrosion resistance, and ability to maintain mechanical properties in challenging environments. Let's delve into the professional knowledge surrounding these components.

Precision Machining Techniques

Precision machining involves the use of advanced techniques to create intricate parts with tight tolerances. For stainless steel, this process is particularly demanding due to the material's hardness and tendency to work harden. Key machining techniques include:

1.CNC Machining: Computer Numerical Control (CNC) machining is the backbone of precision manufacturing. It allows for precise control over cutting tools, ensuring consistent quality and adherence to design specifications.

2.Turning and Milling: These processes are used to shape stainless steel parts by removing material with cutting tools. Turning is ideal for cylindrical parts, while milling is used for more complex shapes and features.

3.Grinding: Precision grinding is employed to achieve tight tolerances and a smooth surface finish. It is essential for parts requiring high dimensional accuracy and surface quality.

Stainless Steel Grades

Stainless steel is categorized into different grades based on its chemical composition and properties. Common grades used in precision machining include:

1. 300 Series (e.g., 304, 316): Known for their excellent corrosion resistance and formability, these grades are widely used in industries requiring high cleanliness and durability.

2. 400 Series (e.g., 410, 416): These grades offer good machinability and moderate corrosion resistance. They are often chosen for parts requiring higher hardness and wear resistance.

Design Considerations

Designing precision machined stainless steel parts involves considerations to optimize performance and manufacturability:

1.Tolerances: Specify tight tolerances to ensure the part fits seamlessly into assemblies and functions as intended.

2.Surface Finish: Determine the required surface finish based on functional and aesthetic requirements. Finer finishes may require additional machining operations.

3.Material Selection: Choose the stainless steel grade that best suits the application’s mechanical and environmental requirements.

Precision machined stainless steel parts find application in diverse sectors:

1.Medical Devices: Surgical instruments and implants benefit from stainless steel’s biocompatibility and corrosion resistance.

2.Automotive: Components such as engine parts and exhaust systems require stainless steel for its heat resistance and durability.

3.Aerospace: Critical aircraft components demand materials that can withstand extreme temperatures and harsh environments.

Ensuring the quality of precision machined stainless steel parts is paramount:

1.Dimensional Inspection: Use coordinate measuring machines (CMMs) to verify dimensional accuracy.

2.Surface Analysis: Conduct surface roughness measurements and visual inspections to assess finish quality.

3.Material Testing: Employ techniques like spectroscopy and hardness testing to verify material properties.

Professional knowledge surrounding precision machined stainless steel parts encompasses a blend of advanced machining techniques, meticulous design considerations, careful material selection, and rigorous quality control measures. By understanding these aspects, manufacturers can produce components that meet the stringent requirements of modern industries, ensuring reliability, longevity, and performance in demanding applications.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog