Clădirea 49, Parcul Industrial Fumin, satul Pinghu, districtul Longgang

Duminică închis

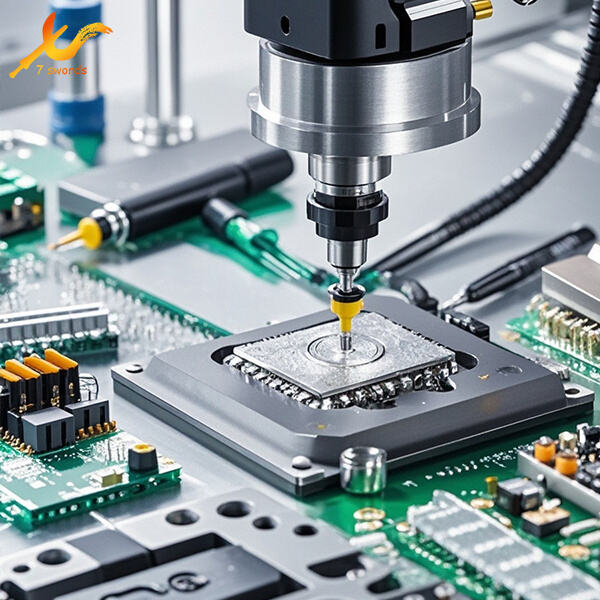

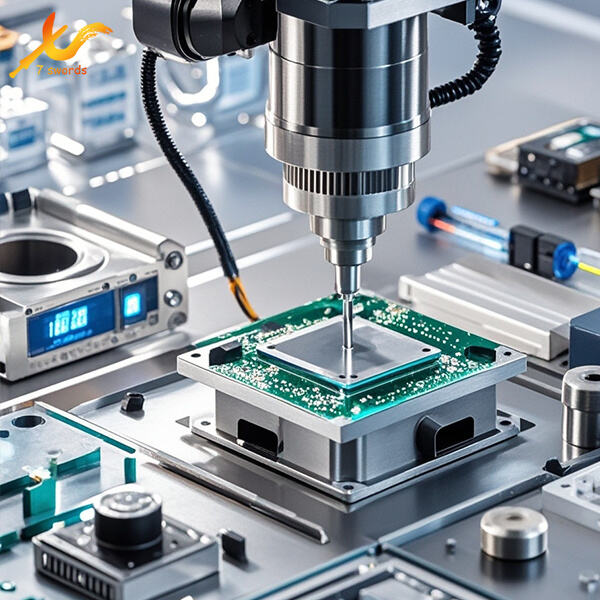

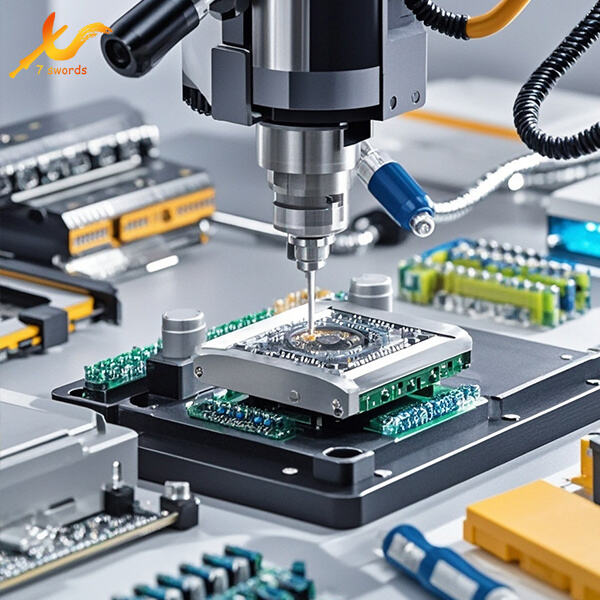

We know that electronics are shrinking and becoming ever more sophisticated. For example, we have tiny mobile phones that we can carry around and high-tech medical devices that help to save lives. So, precision engineering is so much required to get these devices running fine. But just how do companies manufacture such intricate pieces that fit so well with each other? To accomplish this, they employ special machines known as CNC Machines.

CNC stands for Computer Numerical Control, which are essentially computers controlling special tools So they can move accurately, and ultimately do pretty much what we tell them. In the semiconductor domain, CNC machines are used for producing extremely small parts which when put together, fit precisely. Wanted by the gadget builders for crafting smallaswoon in electronics, These machines are capable of producing very intricate work, a big advantage for companies in the business of making electronic devices that perform specific tasks with great precision.

With technology constantly evolving, the role of precision engineering and CNC machines will continue to grow in importance for producing electronics. Tight tolerances in the creating of complex electronics parts at warp speed is critical to setting innovation on overdrive so that we can even begin to conceive them in future products. This allows companies to move faster and this translates into cost savings and more rapid time to market.

The machine tools we call CNCs are powerful monsters that can build intricate electronic parts with ease. The advancements enable the machines to quickly produce parts with extremely high accuracy. As a result, companies can create even more improved and less expensive consumer electronics than they could develop before. Which will in turn further innovation within the electronics industry and new exciting products that benefit our daily lives.

The reason for this is because CNC machines have dual ownership which allows them to be used for both prototyping and taking the design into full production. The second point about innovation = new product that is true for many other areas, including creating a new electronic device which you should always prototype first. A working prototype is a device that serves as the model for testing the design before it goes to full scale production. These prototypes can be manufactured very quickly using CNC machines and tested to fit well in their design by companies. Once the fit and look are confirmed, CNC machines can produce those final parts with intricate accuracy to mate snugly and seamlessly —just as they were intended.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. Toate drepturile rezervate — Politica de Confidentialitate - Blog