Дом 49, промышленный парк Фумин, деревня Пинху, район Лунган

Воскресенье Закрыто

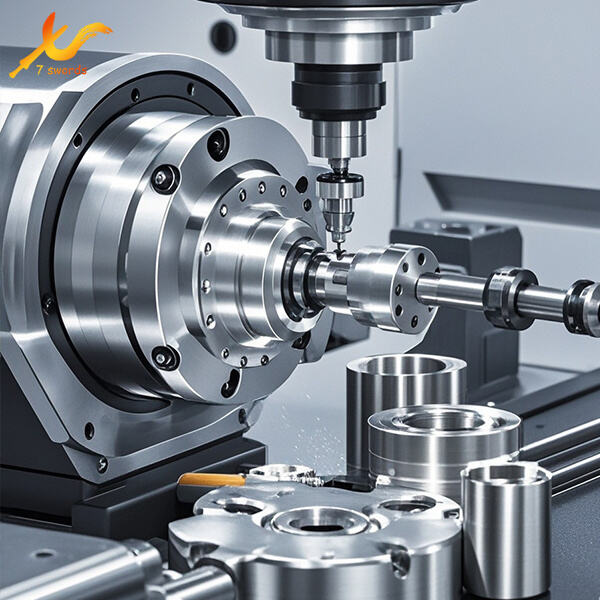

Swords Precision is a unique metal parts manufacturer. This is done using highly advanced machines. CNC stands for computer numerical control, and that's the technology they use. This is where computers assist in controlling the machines to very precisely cut the metal. Hence, in this piece of writing, we will discuss CNC turning solutions, how they work and why they are crucial for manufacturing metal components.

A CNC turning solution is another step in improving the manufacturing process. That is the machines are controlled by computers that direct how they cut the metal. The CNC technology enables the machines to operate efficiently and cuts them perfectly. This is a substantial shift in our manufacturing paradigm, and it holds immense significance for a variety of industries. CNC turning enables companies to manufacture parts to precise dimensions since most holes, slots, edges, and features on the parts must match the engagement points of connected or add-on components.

CNC turning solutions offer some of the best quality and speed available. Those ski-hill parts come out perfectly because the machines can make real precise cuts. This is essential for an efficient long-lasting equipment. This means accurate parts are made, fit together and function as required. Moreover, unlike older machines, CNC machines can run for very long hours without rest. That means they can produce many parts quickly and with minimal waste. Such machines ultimately save organizations time and money, due to their efficiency.

CNC turning solutions make workers much more productive. This means that the newer machines will work faster and smarter compared to the older machines. This is because they have unique features that enable them to create intricate shapes and designs. It saves time and helps control costs. CNC machines can work with a wide variety of metals, making them highly versatile. This means they are suitable for many different projects, from tiny details to enormous structures. They are utilized across a wide range of industries, including automotive, aerospace, and manufacturing, due to their ability to process various materials.

The CNC turning option is phenomenal for manufacturing extremely complex pieces. That means the machines can mold shapes and designs that are difficult to create by hand. If a user needed his part to be a different design or he wanted some special curves in his part, it is a simple piece of cake for a CNC machine. Using this technology, individuals can create things they would find it very hard to build otherwise. Such detailed customization offers ground-breaking opportunities for inventors and manufacturers to create innovative products that surpass the competition.

One other awesome thing about CNC turning solutions is the ability to customize them according to your needs. This means the machines can be configured in several different ways to create parts that are just right for your project. Why this matters is because you get what you want without sacrificing quality or correct shape of the different components. The machines can also be set up to produce many parts simultaneously, saving both time and money. Because of this versatility, CNC turning solutions are popular with companies that must quickly get custom parts.

We have ISO9001 certificate, ISO14001, ISO45001, medical CNC Turning Solutions aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

We offer OEM and ODM services Minimum quantity of orders is CNC Turning Solutions We can provide quotations within 3 hours Production of samples takes 1 to three working days Bulk delivery takes between 7 and 14 days Our production capacity per month exceeds 300 000 pieces

Our professional engineering team is always online, ready to answer your questions. They are highly skilled and have the experience to address your concerns. Custom high precision parts CNC Turning Solutions: +/-0.01 mm, Special area: +/-0.005 mm.

CNC Turning Solutions production equipment includes: 3-axis (4-axis), 5-axis up to 6-axis equipment. We have a wide range of processing capabilities that include turning, milling and drilling, grinding and EDM, 3D Printing. We are able to work with a variety of different materials like aluminum, brass and copper stainless steel plastics, and composites.

Авторские права © Shenzhen Perfect Precision Products Co., Ltd. Все права защищены — Персональные данные - Блог