The Future of CNC Machining: Trends to Watch Out For

The world of CNC (Computer Numerical Control) machining is evolving rapidly, driven by advancements in automation, artificial intelligence, and sustainable manufacturing. As industries demand higher precision, efficiency, and eco-friendly solutions, several key trends are shaping the future of CNC technology. Here’s what to watch out for in the coming years.

1. Smart Manufacturing & AI Integration

CNC machining is becoming smarter with AI-powered predictive maintenance and real-time optimization. Machine learning algorithms analyze production data to reduce errors, improve tool life, and enhance efficiency. Factories are adopting IoT-enabled CNC machines that communicate with other systems for seamless automation.

2. Additive & Hybrid Manufacturing

The line between CNC machining and 3D printing is blurring. Hybrid machines now combine subtractive and additive processes, allowing manufacturers to build complex parts with layered printing and precision milling in a single setup—reducing waste and production time.

3. Sustainable Machining Practices

With stricter environmental regulations, manufacturers are turning to energy-efficient CNC machines, biodegradable coolants, and recycled materials. High-speed machining techniques are also being optimized to minimize material waste and energy consumption.

4. Automation & Robotics

Robotic arms and cobots (collaborative robots) are increasingly used alongside CNC machines for loading, unloading, and inspection tasks. This shift reduces labor costs and improves consistency in high-volume production.

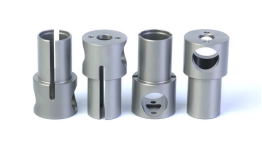

5. Advanced Materials & Micro-Machining

From aerospace-grade titanium to carbon-fiber composites, CNC machines are adapting to cut harder, lighter materials. Meanwhile, ultra-precision micro-machining is enabling innovations in medical devices and electronics.

6. Cloud-Based CNC Systems

Cloud computing allows operators to monitor and control CNC machines remotely, enabling real-time adjustments, software updates, and global collaboration. This trend supports agile manufacturing and rapid prototyping.

The future of CNC machining is digital, automated, and sustainable. As AI, hybrid manufacturing, and green practices take center stage, businesses that embrace these trends will lead the next industrial revolution.