CNC (Bilgisayar Sayısal Kontrol) makanesi, özellikle kalıp üretimi alanında modern imalatta ayrılmaz bir teknoloji haline gelmiştir. Bu blog yazısı, CNC makinelerinin kalıp üretimi üzerindeki çeşitli uygulamalarını inceleyerek avantajlarını, tekniklerini ve gelecek vaatlerini ışıklandırır.

CNC işleme nedir?

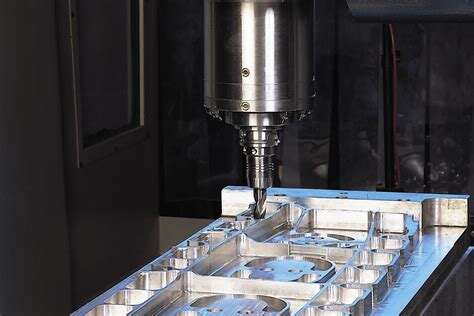

CNC makinalama, bilgisayar kontrolü altındaki makineleri kullanarak metaller, plastikler, ahşap ve cam gibi malzemeleri kesme ve şekillendirme amacıyla kullanılan bir üretim sürecidir. Süreç, kesim araçlarının hareketini kontrol etmek için önceden programlanmış bilgisayar yazılımlarından yararlanır ve bu da nihai üründe yüksek hassasiyet ve tutarlılık sağlar.

Mold Üretiminde CNC Makinalamanın Uygulamaları

1. Karmaşık Tasarım ve Yüksek-Hassasiyet Gereksinimleri

CNC makinalama, karmaşık geometriler ve yüksek-hassasiyetli kalıplar yapmakta uzmandır. Bu, otomotiv, havacılık ve tıp cihazları gibi bileşenlerin sıkı belirtilere uyması gereken endüstrilere özellikle önemlidir. Örneğin, CNC frezeleme, yüksek yüzey kalitesi gereksinimlerine uygun detaylı boşluk yapıları oluşturabilir, bu da onu plastik enjeksiyon kalıbı üretimi için ideal hale getirir.

2. Çok-Eksen Makinalama

Çok eksenli CNC makineleri, geleneksel makinelerle zor ya da imkansız olan karmaşık şekiller ve eğriler oluşturmayı sağlar. Bu yetenek, yüksek hassasiyet ve doğruluk gerektiren çok eksenli bileşik kalıbın üretilmesi için kritiktir.

3.Malzeme Esnekliği

CNC makineleri, metaller, plastikler, ahşap ve cam gibi geniş bir malzeme yelpazesinde çalışabilir. Bu esneklik, küçük prototiplerden büyük üretim serilerine kadar çeşitli türde kalıpların yapımında kullanılmasını mümkün kılar. Örneğin, alüminyum, güçlülüğü, esnekliliği ve hafif ağırlığı nedeniyle döküm kalıpları için yaygın olarak kullanılır.

4.Otomasyon ve Etkinlik

CNC makinalandırma, elle yapılan işgücüne olan ihtiyacı azaltarak üretim verimliliğini artırır. Bu otomasyon aynı zamanda tutarlı kalite sağlar ve insan hatasının olasılığını azaltır. CAD/CAM sistemlerinin entegrasyonu, makinalandırma sürecindeki hassasiyeti ve doğruluğu daha da artırır ve karmaşık geometrilere kolayca yer verilmesini sağlar.

5. Maliyet Etkin Üretim

CNC makinalara yapılan başlangıçtaki yatırım önemli olabilir, ancak uzun vadedeki avantajlar, azaltılmış işgücü maliyetleri, artan üretkenlik ve birim başına daha düşük üretim maliyetleridir. CNC makinalandırması, başlangıçtaki kurulum maliyetlerinin birçok ünitede paylaştırıldığı yüksek hacimli üretim serileri için özellikle maliyet etkilidir.

6. Kalite Kontrolü ve Tutarlılık

CNC makinalaması, kesme, frezeleme ve delgilleme işlemlerinde kesinlik aracılığıyla istisnaî kalite kontrolü sağlar. Gelişmiş yazılımlar ve sensörlerin kullanımı, her bir parçanın tam belirtilere göre üretilmesini sağlar ve büyük üretim serileri boyunca tutarlılığı korur.

7.Inovatif Teknikler

CNC makinalamasında yapılan son geliştirmeler arasında, kompleks profiller ve kontroller içeren kalıplarda oluşturmak için temel olan alt kesimler gibi özel işleme tekniklerinin kullanımı yer almaktadır. Ayrıca, yapay zeka ve makine öğrenimi algoritmalarının entegrasyonu, araç yollarını optimize ediyor ve makinalama sürecindeki karar verme süreçlerini geliştirmektedir.

Olay Çıkarımları ve Gerçekteki Uygulamalar

1.Otomotiv Sektörü

Otomotiv sektöründe CNC makinalaması, motor blokları, vücut panelleri ve diğer bileşenler için kalıplar üretmek için kullanılır. CNC makinalamanın yüksek keskinliği ve verimliliği, bu parçaların sıkı kalite standartlarını karşılamasını sağlar.

2.Havacılık Endüstrisi

Uzay mühendisleri, hava ve uzay araçları için hafif ama dayanıklı parçalar oluşturmak üzere CNC machinetamına bağlıdırlar. Karmaşık geometriler ve yüksek hassasiyetli bileşenler üretme yeteneği bu endüstride kritik öneme sahiptir.

3.Tıbbi Cihazlar

Tıp endüstrisi, cerrahi aletler ve teşhis ekipmanları için kesin kalıplar üretmek amacıyla CNC machinetamından faydalanır. CNC machinetaminin yüksek doğruluk ve tutarlılığı, bu bileşenlerin güvenli ve güvenilir olması için temin edilmiştir.

Gelecek Prospekleri

Teknoloji sürekli gelişmeye devam ederken, CNC machinetamının kalıp imalatında giderek daha önemli bir rol oynayacağı beklenmektedir. Yapay zeka ve makine öğrenimi entegrasyonu, sürecin verimliliğini ve doğruluğunu daha da artıracaktır. Ayrıca, yeni malzemelerin geliştirilmesi ve ileri machining teknikleri, çeşitli endüstrilerde CNC machinetaminin kapasitelerini genişletecektir.