Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Chủ nhật Nghỉ

Loại: Broaching, Khoan, Etching / Machining Hóa học, Machining Laser, Phay, Các Dịch vụ Machining Khác, Tiện, Wire EDM, Phân mẫu Nhanh

Micro Machining hoặc Không Micro Machining

Model Number: Theo yêu cầu

Vật liệu: Hợp kim nhôm

Kiểm soát chất lượng: Chất lượng cao

Số lượng tối thiểu: 1pcs

Thời gian giao hàng: 7-15 Ngày

OEM/ODM: Dịch vụ Machining CNC OEM ODM Phay Tiện

Dịch vụ của chúng tôi: Dịch vụ Machining CNC Theo yêu cầu

Chứng nhận: ISO9001:2015/ISO13485:2016

Tổng quan về Sản phẩm

Trong thế giới sản xuất cạnh tranh ngày nay, độ chính xác và tính đa dụng là điều cần thiết để đáp ứng các nhu cầu đa dạng của nhiều ngành công nghiệp khác nhau. Các dịch vụ phay CNC vật liệu nhôm, cắt dây và dập nổi kết hợp các công nghệ gia công tiên tiến để cung cấp các bộ phận bằng nhôm chất lượng cao, được chế tạo theo yêu cầu. Dù là cho ngành hàng không vũ trụ, ô tô, điện tử hay sản phẩm tiêu dùng, những quy trình này cho phép tạo ra các thiết kế phức tạp, dung sai chặt chẽ và các bộ phận bền bỉ được tùy chỉnh theo yêu cầu cụ thể.

1. Nhẹ và chắc : Nhôm cung cấp sự cân bằng giữa độ mạnh mẽ và trọng lượng nhẹ, khiến nó lý tưởng cho các ngành như hàng không vũ trụ và ô tô.

2. Khả năng chống ăn mòn : Nhôm tự nhiên hình thành một lớp oxit bảo vệ, cung cấp khả năng kháng gỉ và ăn mòn tuyệt vời.

3. Tính dẫn nhiệt và điện : Độ dẫn điện cao của nhôm khiến nó lý tưởng cho các ứng dụng điện tử và điện.

4. Tái chế được : Aluminum có thể tái chế hoàn toàn, làm cho nó trở thành lựa chọn thân thiện với môi trường cho các thực hành sản xuất bền vững.

Vật liệu Nhôm CNC: Định hình chính xác cho các bộ phận phức tạp

1.Độ chính xác cao

Máy phay CNC được trang bị các công cụ được điều khiển bằng máy tính có thể tạo ra các bộ phận chính xác cao với kết quả lặp lại. Mức độ chính xác này là thiết yếu cho các ngành công nghiệp mà hiệu suất và an toàn là ưu tiên hàng đầu.

2.Hình dạng và Thiết kế Tùy chỉnh

Từ hình trụ đến các hình dạng phức tạp, tinh vi, máy phay CNC có thể xử lý nhiều loại hình học của các bộ phận khác nhau, bao gồm ren, rãnh và đường cong, một cách dễ dàng.

3.Sản xuất nhanh chóng

Máy phay CNC có thể sản xuất các bộ phận nhôm chất lượng cao trong một thời gian ngắn, khiến nó trở nên lý tưởng cho cả việc tạo mẫu thử và sản xuất số lượng lớn.

4.Tiết kiệm chi phí

Tốc độ và hiệu quả của quá trình gia công máy phay CNC dẫn đến chi phí nhân công thấp hơn và thời gian sản xuất được rút ngắn, làm cho nó trở thành một lựa chọn tiết kiệm chi phí cho các bộ phận nhôm chính xác.

Cắt dây: Thiết kế tinh xảo và chi tiết nhỏ

1.Chính xác cao và Độ phức tạp

Cắt dây có thể đạt được những chi tiết cực kỳ tinh xảo và hình dạng phức tạp mà khó có thể sản xuất bằng các phương pháp gia công truyền thống. Điều này khiến nó trở nên lý tưởng cho các thiết kế错 phức tạp và các bộ phận mỏng manh cần độ chính xác cao.

2.Quy trình Không Tiếp Xúc

Vì cắt dây không liên quan đến tiếp xúc vật lý với vật liệu, nó giảm thiểu nguy cơ biến dạng hoặc ứng suất trên nhôm, bảo vệ tính toàn vẹn của vật liệu và đảm bảo kết quả chất lượng cao.

3.Cắt và Hình Dạng Theo Yêu Cầu

Dù bạn cần các đường cong tùy chỉnh, lỗ khoan hay họa tiết phức tạp, cắt dây cho phép linh hoạt hoàn toàn trong thiết kế, làm cho nó phù hợp cho các ngành công nghiệp yêu cầu các bộ phận nhôm chuyên dụng cao.

4.Hiệu quả và Đa năng

Cắt dây là một quy trình đa năng có thể sử dụng trên vật liệu nhôm mỏng hoặc dày, mang lại kết quả tuyệt vời cho cả dự án nhỏ và lớn.

Ép Nhũ: Thêm Vết May Và Chi Tiết Cho Các Bộ Phận Nhôm

1.Sự hấp dẫn thẩm mỹ

Việc tạo nổi (embossing) thêm vào một kết cấu thị giác hấp dẫn cho các bộ phận nhôm, làm cho chúng nổi bật trong các sản phẩm tiêu dùng, biển báo và ứng dụng xây dựng thương hiệu. Nó lý tưởng để tạo ra các mẫu mã, logo và thiết kế thu hút về mặt thị giác.

2.Cải thiện độ bám và chức năng

Các bề mặt được tạo nổi trên các bộ phận nhôm có thể cung cấp độ bám tốt hơn, điều này đặc biệt hữu ích trong các sản phẩm như tay cầm, núm vặn và các bộ phận ô tô.

3.Thiết kế tùy chỉnh

Tạo nổi cho phép thiết kế tùy chỉnh cao, dù bạn cần một logo đơn giản hay các họa tiết phức tạp, mang lại sự linh hoạt để đáp ứng các yêu cầu thương hiệu hoặc chức năng cụ thể.

4.Độ bền

Các họa tiết được tạo nổi được tích hợp trực tiếp vào vật liệu, khiến chúng bền lâu và kháng mài mòn, đảm bảo tuổi thọ của bộ phận trong các môi trường khắc nghiệt.

kết hợp gia công CNC Nhôm, Phay Trục, Cắt dây và Tạo nổi để đạt Kết quả Tối ưu

Ứng dụng của Dịch vụ Phay CNC Nhôm, Cắt dây và Ép nổi

Sự kết hợp của vật liệu nhôm CNC, phay tiện, cắt dây và dập nổi tạo ra một giải pháp mạnh mẽ và tiết kiệm chi phí cho sản xuất chính xác. Bất kể bạn cần các bộ phận nhôm phức tạp với các đường cắt và họa tiết chi tiết hoặc các thành phần được thiết kế tùy chỉnh với bề mặt đánh bóng, những kỹ thuật gia công tiên tiến này đảm bảo chất lượng cao, bền và thẩm mỹ đẹp.

Q: Các cấp độ nhôm nào phù hợp nhất cho gia công CNC?

A: Các cấp độ nhôm phổ biến bao gồm:

6061:Đa dụng và chống ăn mòn tốt, lý tưởng cho các ứng dụng cấu trúc và hàng không vũ trụ.

7075: Cường độ cao và trọng lượng nhẹ, thường được sử dụng trong ngành hàng không vũ trụ và ô tô.

5052: Tuyệt vời cho các ứng dụng yêu cầu cường độ mệt mỏi cao và khả năng hàn tốt.

Q :Gia công tiện CNC hoạt động như thế nào với nhôm?

A: Tiện CNC quay chi tiết làm việc bằng nhôm ở tốc độ cao trong khi các công cụ cắt loại bỏ vật liệu để tạo hình dạng tròn. Nó lý tưởng để sản xuất trục, ống lót và các bộ phận tròn khác.

Q:Gì là cắt dây và nó được sử dụng như thế nào trong gia công CNC nhôm?

A:Cắt dây, còn được gọi là EDM (Máy gia công phóng điện), sử dụng một sợi dây mang điện mỏng để cắt các hình dạng chính xác vào nhôm. Nó rất phù hợp cho các thiết kế phức tạp, dung sai chặt chẽ và những khu vực khó tiếp cận.

Q:CNC có thể thực hiện nổi chữ trên nhôm không?

A:Có! Máy CNC có thể nổi các hoa văn, logo hoặc kết cấu lên bề mặt nhôm bằng cách sử dụng khuôn hoặc công cụ chính xác. Nổi chữ làm tăng tính thẩm mỹ và thương hiệu, thường được sử dụng trong các ứng dụng trang trí hoặc công nghiệp.

Q:Những lợi ích của việc sử dụng nhôm trong quá trình CNC là gì?

A :1.Nhẹ và mạnh: Thích hợp cho ngành công nghiệp ô tô, hàng không vũ trụ và điện tử.

2.Khả năng chống ăn mòn: Phù hợp cho các ứng dụng ngoài trời và hàng hải.

3.Độ dẫn nhiệt: Tốt cho tản nhiệt và các linh kiện điện tử.

4.Độ dễ dàng khi gia công: Giảm thời gian sản xuất và độ mòn của công cụ.

Q :Có gì khác nhau giữa gia công phay CNC và tiện đối với nhôm?

A: Gia công tiện: Phù hợp nhất cho các chi tiết tròn hoặc hình trụ.

Gia công phay: Được sử dụng cho các hình dạng phức tạp, bề mặt phẳng và các chi tiết có nhiều đặc điểm.

Q: Các máy CNC có thể đạt được độ chính xác như thế nào khi gia công nhôm?

A: Máy CNC có thể đạt độ chính xác lên đến ±0.001 inch (0.0254 mm), tùy thuộc vào máy móc và yêu cầu của dự án.

Q: Bề mặt hoàn thiện có gì khác nhau sau khi cắt dây hoặc dập nổi nhôm?

A: Cắt dây: Cho bề mặt mịn nhưng có thể cần đánh bóng để có bề mặt tinh hơn.

Ép nổi: Tạo ra các hoa văn nổi hoặc lõm với bề mặt hoàn thiện có kết cấu, tùy thuộc vào công cụ.

Q: Làm thế nào để chọn dịch vụ CNC phù hợp cho gia công nhôm?

A: Kiểm tra kinh nghiệm với vật liệu nhôm.

Xác nhận có các công cụ tiên tiến cho quá trình phay, cắt dây và ép nổi.

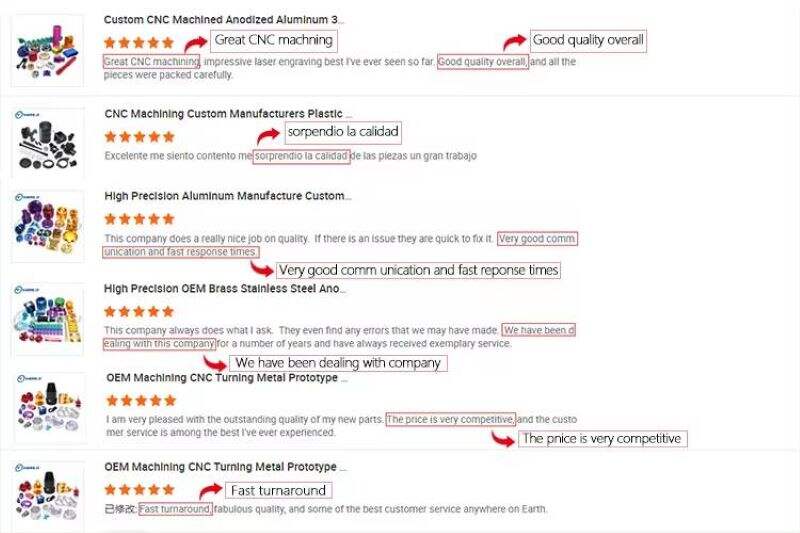

Tìm kiếm những đánh giá tốt và lịch sử hoạt động đáng tin cậy.

Đảm bảo mức giá cạnh tranh và thời gian giao hàng.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Chính sách bảo mật—Blog