Agricultural Machinery

With the development of modern agriculture, agricultural mechanization has become the key to improving production efficiency and reducing labor intensity.

The materials of agricultural machinery need to be able to withstand harsh working environments, such as open air, dusty, humid, and dirty environments, as well as the corrosive effects of contact with soil, fertilizers, pesticides, feces, rotten plants, and water. Therefore, the materials of agricultural machinery should have the properties of corrosion resistance, wear resistance, friction reduction, impact resistance, and fatigue resistance, at the same time, the cost should be low and the raw materials should be based on domestic resources.

What qualities do agricultural machinery parts require?

1. Durability: Agricultural machinery usually works in harsh environmental conditions, such as mud, dust, and moisture, so parts are required to have high durability and long life.

2. High strength: Agricultural machinery is subject to large loads during operation, so parts need to have sufficient strength to withstand these loads.

3. Corrosion resistance: Since agricultural machinery is often exposed to the outdoors and chemicals (such as fertilizers and pesticides), parts need to have good corrosion resistance.

What do we do?

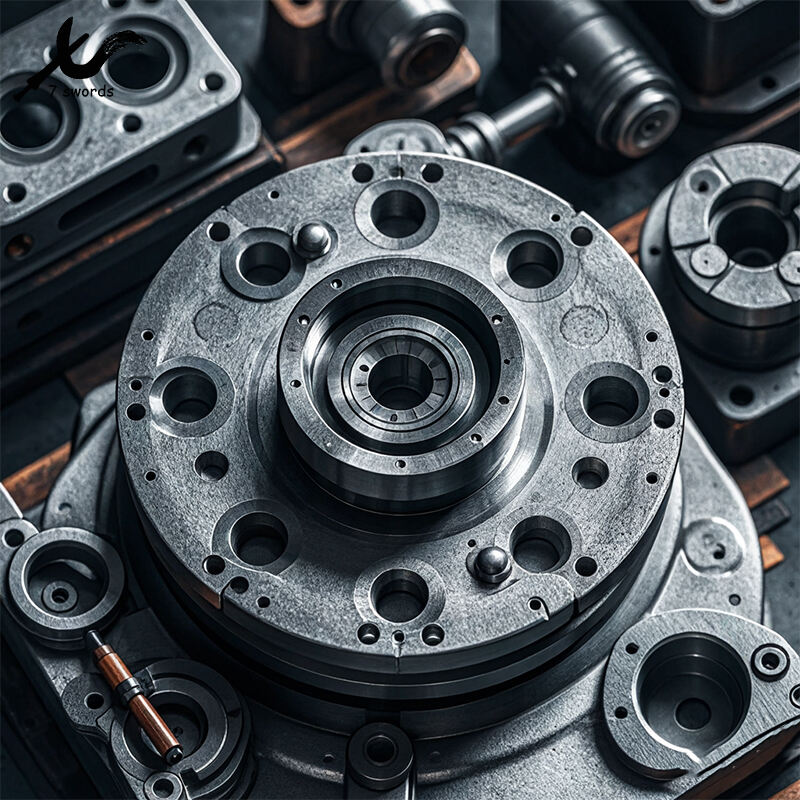

1. High-precision component processing

Advanced CNC machine tools are used to precisely process key components of planters and harvesters to ensure accurate matching of components and stability of operation.

2. High-strength design

All parts are made of high-strength alloy steel, and through a precise heat treatment process, the stability and reliability of the parts under high load are ensured.

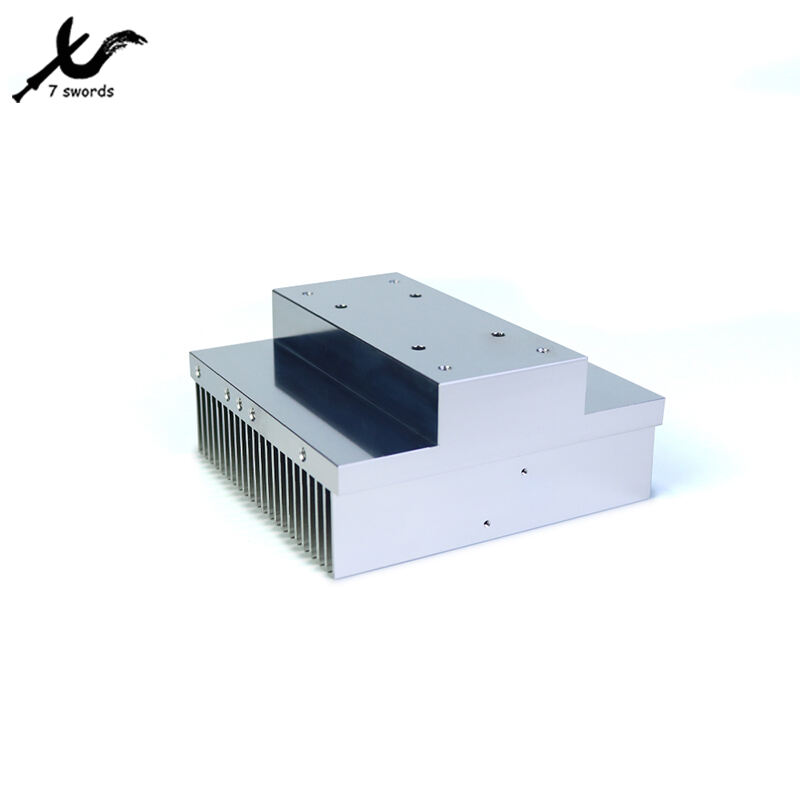

3.Surface treatment

Use advanced surface treatment technologies such as anodizing, electroplating, painting, etc. to enhance the corrosion resistance of parts; electroplating such as zinc plating, chrome plating or spraying anti-corrosion coatings to effectively resist the erosion of moisture, soil and chemical fertilizers.

4. Wear-resistant material processing

In response to the requirements for wear resistance in agricultural operations, special materials and surface hardening technology are used to improve the durability of mechanical components.