Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

Ever wonder how your favorite toys, useful kitchen utensils and essential car parts are made? Injection plastic molding is a popular method for creating contaminants such as these. It is interesting because it is using melted plastic to form shapes to specifications. So here’s what they do: They heat the plastic until it melts, then push this melted plastic into a mold. Then, after it has been put into the mold, it cools down and hardens, resulting in the completed product you see and use on a daily basis.

Injection plastic molding is one of the most preferred ways to create products by the companies. A major advantage is that the process yields highly accurate and precise shapes. This is to ensure that the product is the same size and details as the designers intended it to be.

So, another wonderful thing about injection molding for plastic is that it is a quick process to produce in bulk. Its fast process allows companies to manufacture many products within a brief span of time. This is particularly desirable when specific products are in great demand.

Injection plastic molding is also capable of making a wide array of shapes and sizes. A company might require small pieces for a toy or large pieces for furniture — this technology can be used for all types of objects.

For example, if it has to withstand high temperatures use a plastic called nylon, which is heat tolerant. However, if a product needs to be extremely strong, then polycarbonate would be better choice (one type of the so-called plastic). Knowing the types of plastics enables the best choice to be made for any given product.

Use the Right Plastic: Selecting the right plastic for the product being manufactured is paramount. The proper material will ensure that the final product will withstand whatever it faces under the toughest circumstances.

Cooperate With a Good Company – Indeed, you should cooperate with a good injection plastic molding company. Illustrating this point, Swords Precision is a company with years of experience in this sector. They are trained with the knowledge and skills needed to ensure that quality products are produced successfully.

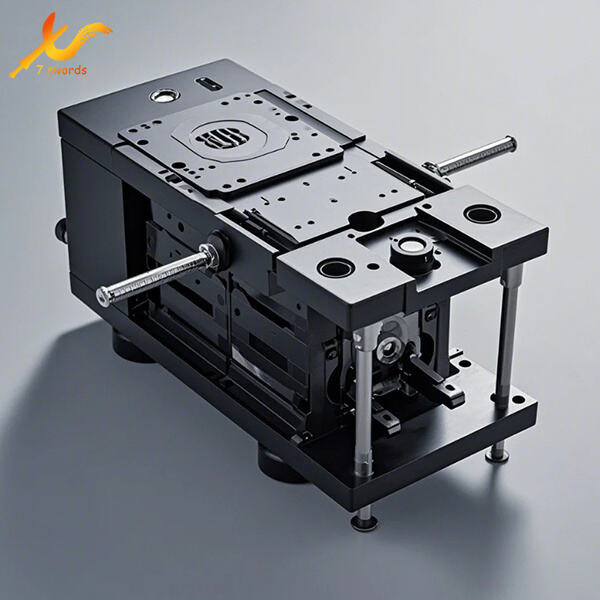

Our production equipment includes 3-axis (4-axis), 5-axis, up to 6-axis machines. We have a broad range of processing capabilities, including turning, milling, grinding, drilling as well as injection plastic molding, 3D Printing. We can work with a range of materials, including copper, aluminum, brass and stainless steel, plastics, composites and crafting components that meet any industrial need.

We offer OEM and ODM services The minimum order amount is 1 unit Quotes are sent within three hours Sample production requires 1 to 3 days Bulk delivery can take 7 to injection plastic molding Our monthly production surpasses 300 000

We have ISO9001 certificate, ISO14001, ISO45001 injection plastic molding ISO13485, aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

Our team of experienced engineers is always available, ready to respond injection plastic molding to your inquiries. They have the expertise and knowledge to address all your concerns. Custom high precision partsTolerance: +/-0.01 mm, Special space: +/-0.005 mm.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog