Edificio 49, Fumin Industrial Park, Pinghu Village, Longgang District

Domingo pechado

For example, in metal forming, we manipulate special tools to progressively deform/bend/ shear metal sheets into desired instructions. This job is crucial because metals produce a lot of products we see and use daily, such as airplanes, cars, and even children's toys. We are Swords Precision, masters of metal, here to produce incredible things to make life better and more enjoyable.

Treading ground on metal forming to cut and shape metal. It is also an art, one that takes skill and practice and a whole lot of creativity. At Swords Precision we take pride in what we do. Every time we work with metal, we aim to create something useful—and beautiful. Again, we use tools to create beautiful metal designs, just like a painter uses brushes to create a picture.

Fabricante de pezas metálicas personalizadas is a process that begins with a piece of metal. This metal can take on many forms and price tags. Next, we utilize some tools (hammers, pliers, presses, etc.) to bend and shape the metal into whatever we need it to look like. This sometimes takes time, because we want everything to be perfect. But something really strong that can be adapted for lots of use is worth the effort.

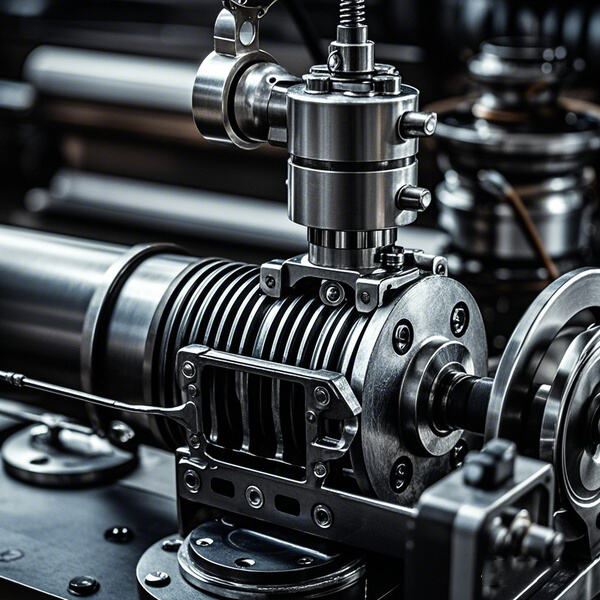

At Swords Precision, metal forming is accomplished with easier and more intricate techniques. One method is CNC machining. This is where a computer controls a machine that molds the metal. This is what allows us to get the ideal shape each time, which really takes the work out of our jobs. We also use a process called laser cutting. Here, a laser beam makes a very precise cut into the metal. It helps us cut the metal accurately and precisely and is needed to produce good quality metal products.

Heat is a key factor in metal forming. It also (in pertinent part) makes the metal softer, that is, more malleable, less brittle, easier to work with. At Swords Precision, we apply heat in a very specific way in a process we call forging. We heat the metal in forging until its hot. Next, we apply pressure to twist and configure it. We can use this technique to develop very strong metal products, with high barriers to the effort needed to deform them. Heat and force are used to make strong, durable products.

Swords Precision so we continually work to expand the possibilities of metal forming. Using our advanced techniques and bespoke tools, we can create virtually any design you can imagine. You could say we even made metal products used in outer space! We are always searching for new ways to improve our techniques and processes so that we can keep producing the best products possible for our customers.

We offer a wide range of production Metal forming, including 3-axis and 4-axis up to 6-axis. We offer a range of processing capabilities that include turning, milling, and drilling, grinding and EDM, 3D Printing. We work with many different materials like copper, brass and aluminum steel, stainless, plastics and composites.

They have a wealth of Metal forming and knowledge to address all your concerns. Their extensive knowledge and expertise will address your concerns. Custom precision parts tolerances: +/- 1 mm, Special Space: +/0.005 mm

Metal forming have ISO9001 certificate, ISO14001, ISO45001, medical ISO13485, aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

We Metal forming OEM ODM services The minimum order quantity is 1 unit Quotes are delivered within three hours Production samples take 1 to 3 days while bulk delivery is between 7 and 14 days Our monthly production capacity exceeds 300 000 pieces

Copyright © Shenzhen Perfect Precision Products Co., Ltd. Todos os dereitos reservados — Política de Privacidade - Blog