Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

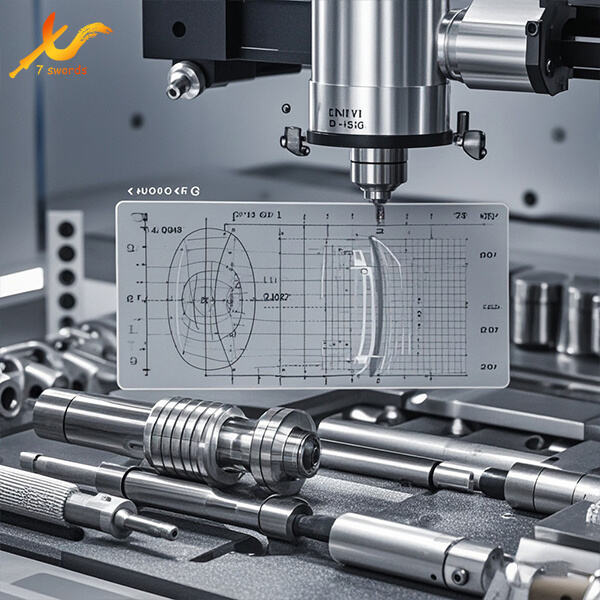

For producing quality-working products, CNC machining tolerances are a must. CNC: Computer Numerical Control This can be accomplished using CNC (Computer Numerical Control) cutting technology, where a number of parts can be automatically cut and shaped from raw bits of material to within even the tightest tolerances. Tolerances are all these tiny differences between the exact measurements that parts and products can allow in order to perform adequately. This is why Swords Precision — a top CNC manufacturer — knows this accuracy is vital. So they created this easy guide to explain everything.

At Swords Precision we appreciate the significance of tight tolerances when it comes to products that require precision. CNC machines are accurate, but they can have a little stupidity too. There are numerous reasons why these errors can occur. Some of the factors that may have a negative impact on the accuracy of the machining process include — but are not limited to — an incorrect machine design, type of material used, errors in handling by the operator as well as environmental conditions.

To avoid making these mistakes, Swords Precision not only ensures all CNC machines are properly calibrated but also checked often. The correct calibration: Naturally, the machinery is set up correctly. The company also utilizes high-quality, purpose-built cutting tools that go a long way in achieving tight tolerances. Thanks to these efforts, Swords Precision is able to produce products at tolerances down to ±0.001 inch.

With assistance from the tips below, which were implemented at Swords Precision to reduce errors as well as necessary best practices, you can increase your likelihood of near strict adherence to the desired measurements. For example, the company has special software that can identify and correct errors in machine programming. The software is so advanced that it essentially adjusts the cutting speeds and feeds on-the-fly while the machine is in operation. This allows for the real-time adjustment that is necessary to meet tolerances at all times during manufacturing.

Swords Precision hires and trains the operators as well as machinists along with technology. Best of the machines and software leads to human error. A variety of continuous training and education programs are offered to prevent errors. Operators to acquire a better skill set enabling them to get more adept and confident in what they do. Operators can be trained to use the best methods for few errors, again critical in precision machining.

To keep everything uniform, Swords Precision always makes sure to use the right tools and equipment that each project needs. Different tools might be needed for each project, as different projects involve different materials and designs. That software also follows the trail of every manufacturing step for all company patents. This program also notifies the operator of any non-conforming outcomes. With close attention to detail and the ability to make necessary adjustments, Swords Precision keeps on target allowing for consistent tolerances across the entire project.

Playing That Ideal The power has never been out of virtual swords forged, but Sordini and Droney brothers have always proved to be very innovative requiring CNC Machining tolerances that border on physically impossible. The organization is perpetually complementary its technology and equipment is state of the art. For example, Swords Precision employs high-speed machining centers. These replace the timevarying processes with much shorter cycle times and hence produce with more precision.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog