Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Zondag Gesloten

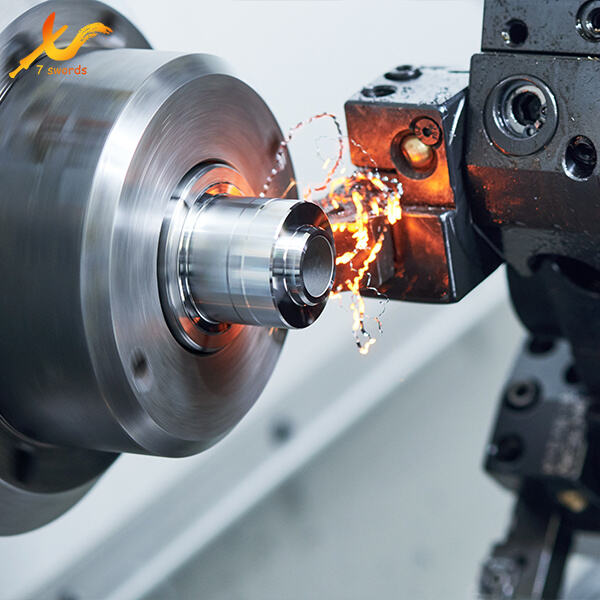

CNC draaien is het proces om veel objecten te maken met behulp van een computergecontroleerde machine. Onze unieke procedure stelt ons in staat nauwkeurige vormen en figuren uit materialen zoals metaal of plastic te produceren. Tijdens de eerste stap van het CNC-draaiingsproces wordt een stuk ruwe materiaal in de draaibank geplaatst. Het materiaal wordt zeer snel door de draaibank gedraaid. Terwijl het materiaal roteert, haalt een werktuig, zoals een lepelvormige schep, alle overtollige stof weg om het vlakke materiaal meer in de gewenste vorm te krijgen. Het snijwerktuig wordt bestuurd door een computersysteem; dit bepaalt de richting en snelheid van het snijden. Op die manier heb je heel goed controle over wat je vormt en hoe. CNC draaien is relevant voor verschillende industrieën omdat het nauwkeurige machineringsservices biedt die al deze industrieën nodig hebben.

Het is een verhaal over cnc draaimaschinen die door de jaren heen veel veranderingen hebben ondergaan. In het verleden werden draaimaschines bediend door mensen, wat betekende dat de productie van een onderdeel verschillende werknemers vereiste. Dit was niet alleen tijdrovend, maar er bestond ook een kans op fouten. Toch, met de uitvinding van computerisatie, kan een groot deel van deze mechanismen worden geautomatiseerd. Deze automatisering laat de machines bijna zelfstandig werken, zodat onderdelen sneller en nauwkeuriger kunnen worden vervaardigd dan ooit tevoren. Tegenwoordig zijn CNC draaimaschines ontworpen om complexe vormen en ontwerpen te produceren die in het verleden bijna of helemaal onmogelijk waren.

Sleutel tot efficiëntere en nauwkeurigere fabrieksbewerkingen. Zoals je kunt zien, is de rol van een CNC-draaimaschine zeer belangrijk voor fabrieken. Deze machines zijn in staat om onderdelen veel sneller te produceren dan traditionele methoden en bieden ook hoge precisie. Terwijl CNC-machines 24/7 kunnen draaien, duurt het handmatige proces veel langer. Fabrieken kunnen, in theorie, vierentwintig uur per dag blijven werken met dit type werk — wat betekent een dramatisch verhoogde productie op lagere productiekosten.

De toepassing van CNC-draaimaschines is breed en omvat sectoren zoals luchtvaart, automotief, medisch en defensie. Deze machines worden gebruikt om onderdelen te maken voor nieuwe motoren, medische apparaten en vliegtuigcomponenten. CNC-draai-technologie is veelzijdig en kan worden toegepast op een breed scala aan toepassingen, waardoor producenten nu voldoen aan een bredere reeks klanteneisen.

CNC draaimaschines hebben een aantal voordelen. De complexe vormen en verticale structuren die moeilijk te produceren zijn met handtechnieken. Ten tweede kan CNC draaien effectief omgaan met verwerking die door betere kwaliteit van de nauwkeurige productie en lagere kosten wordt begrepen. Het kan ook nuttig zijn als je begint te kijken naar het schrijven van prototypes, omdat een CNC draaimaschine bekend staat om herhaalbaarheid in je onderdelen mogelijk te maken. D.w.z. ze kunnen hetzelfde onderdeel keer op keer maken - dit vermindert de kans op fouten (menselijke fout) en waarborgt kwaliteitscontrole.

CNC draaien is een van de dingen waarvan bedrijven die betrokken zijn bij productie het meeste kunnen profiteren. Dit maakt het mogelijk om complexere patronen of vormen te gebruiken, die moeilijk - of zelfs onmogelijk - handmatig te maken zijn. Dit maakt ze ook tot machines met hoge werkprestaties die zijn ingesteld om veel onderdelen snel te produceren, en met strakke tolerenties, waardoor ze perfect zijn voor een massa-productieomgeving.

Swords Precision heeft altijd gestreefd naar de hoogste kwaliteit inCNC-machinedelenCode producten. Een team werkt onophoudelijk samen met een groep ontwerpers, operateurs en ingenieurs om dingen te realiseren. Deze samenwerking is cruciaal om ervoor te zorgen dat hun klanten worden geleverd met producten van de hoogste kwaliteit. Met hun expertise en kennis is Swords Precision ook in staat om hoogwaardige producten te leveren, of het nu gaat om een eenvoudig onderdeel of een complex eindproduct volgens de behoeften van de klanten.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved —Privacybeleid—Blog