Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Søndag Stengt

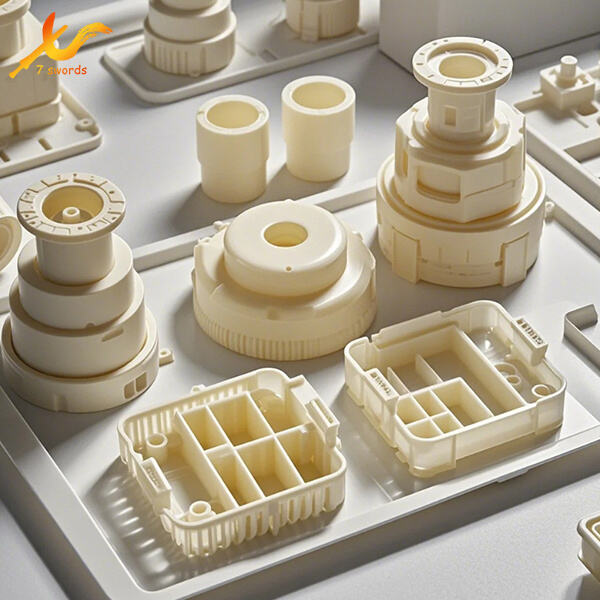

Injeksjonsforming — en unik prosess for å produsere mange plastkomponenter på høy fart. Den ligner på å bruke en kakestempel for å forme kakedeg, bortsett fra at denne prosessen bruker smeltet plast istedenfor deg. Injeksjonsforming brukes til å lage utallige produkter, fra fargerike leker, praktiske glass til robuste telefonhuller. Virtuell prototyping — dette er en avgjørende teknikk som brukes til å lage mye av det du bruker daglig.

Spritforming starter med små plastpiller. Disse pillene er små plastbitter som må verves til de blir smeltet. Den smeltede plasten overføres deretter til en spesialmaskin hvor alt blir skåret opp og blanding, opprettholder nye piller de kan bruke. Deretter presser denne maskinen den smeltede plasten inn i en hul form kalt mold som gir plasten sin endelige utseende. Mould kan være i en rekke former, som for eksempel en lekemann eller et kopp.

Når den smeltede plasten er tatt opp i formen, kjøles den av. Plasten harmer og tar formens shape mens den kjøler av. Når plasten har kjølt fullstendig, åpnes formen, og ut kommer et nytt plastprodukt, klart til bruk! Alt dette skjer raskt, noe som gjør det mulig å gjenta hele prosessen for mange varer og på en kort tid.

Injeksjonsformning har mange fordeler for produksjon av plastprodukter. Den største fordelen er ytelsen sin hastighet. Dette tilnærmingen gjør det mulig å produsere et stort antall produkter raskt, noe som gjør det verdt for virksomheter som søker å produsere store mengder samtidig. Å sikre konsekvens er en annen viktig fordel. Dette betyr at alle produktene ser like ut.” Hvis du lager en leke med injeksjonsforming, så vil alle lekene være identiske. Folk ønsker pene og perfekte ting, derfor har man konsekvens i produksjonen.

En annen grunn injeksjonsformingsformer er veldig nyttig fordi det kan føre til utrolig detaljerte deler. Formverk kan formes med alle slags design og kan åpne opp for kreativitet. Du kunne lage leker som likner på dyr eller morsomme bilder på kopper, for eksempel. Til slutt kan det spare kostnader ved å bruke injeksjonsforming. For bedrifter er det vanligvis mer økonomisk å produsere flere varer samtidig enn å produsere dem én etter én, noe som er grunnen til at de bruker skalaekonomier for å senke alle kostnadene de kan!

Selv om injeksjonsforming er en bra metode for å lage plastprodukter, gir den noen problemer under prosessen. Et vanlig problem de står overfor er at plasten kjøles for raskt, noe som fører til at hele formen ikke fylles ut. Når dette skjer, kommer ikke produktet ut riktig, med hull eller ufullstendig. Dette problemet kan løses ved å oppvarme plasten mer før man former dem, for å la den fylle hele formen fullstendig.

Inntil tider, når plasten smeltes, kan små luftbobler bli fanget i den. Disse boblene kan oppstå hvis plasten ikke er godt nok blanding eller varmes til den nødvendige temperaturen. Luftbobler i plasten vil svake produktet betydelig, og det kan føre til at det feiler tidligere enn forventet. For å unngå dette, kan du røre i plasten grundigere eller oppvarme den til høyere temperaturer for å oppnå en homogen blanding uten bobler.

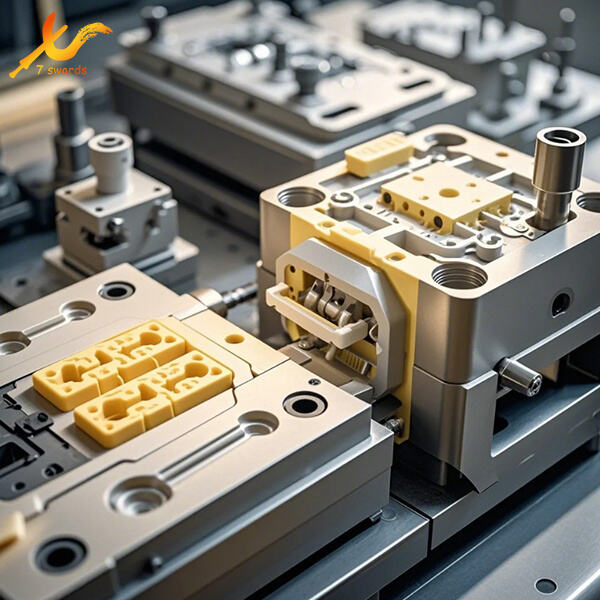

Vi tilbyr OEM- og ODM-tjenester. Minimumsbestillingsmengde er ett stk. Offertesendinger skjer innen tre timer. Produksjon av prøver tar mellom 1 og 3 dager. Massleveranser tar mellom 7 og 14 dager. Vår produksjonskapasitet per måned er mer enn forminjeksjon av plastdeler.

De er ekspertiser med kunnskap til å svare på dine spørsmål. Deres erfaring og kunnskap om injeksjonsforming av plast vil kunne løse dine bekymringer. Toleranser for tilpassede nøyaktige deler: +/- 1 mm, Spesialområde: +/- 0.005 mm

Vårt produksjonsutstyr omfatter 3-akse (4-akse), 5-akse, opp til 6-akse maskiner. Vi har et bredt utvalg av bearbeidingsevner, inkludert skåring, fræsing, slipning, bore og også plastinjeksjonforming, 3D-skriving. Vi kan jobbe med en rekke materialer, inkludert kobber, aluminium, messing og rostfritt stål, plast, sammensatte materialer og lage komponenter som oppfyller alle industrielle behov.

Vi har ISO9001 plastinjeksjonforming, ISO14001, ISO45001, medisinsk ISO13485, luftfart AS9100, Automobil IATF16949, vi kan produsere mekaniske deler, bildele, elektronikkdele, luftfartsdele, medisinsk utstyrdele, kommunikasjonsutstyrdele, ny energidele, bygg- og husholdningsprodukterdele.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Personvernerklæring —Blogg