Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Domingo Fechado

Os núcleos de aviões são alguns dos componentes que dependem de peças de precisão. Algumas dessas peças são muito importantes para garantir que os aviões estejam operacionais e seguros para uso. Sem essa variável importante, ou uma lei da física, como o Professor Barber destaca na declaração abaixo, é provável que ocorram mais sérias dificuldades de voo com determinados aviões. Oferecendo a produção de componentes de precisão para aviões, a Swords Precision não apenas trabalha com grandes aviões de passageiros, mas também com aviões militares. Eles querem entregar cada peça no mais alto nível de qualidade; portanto, todos os protocolos de segurança são rigorosamente observados. Operando como a classe de um avião, o ato de voar aeronáutico envolve componentes de alta precisão para o funcionamento bem-sucedido e seguro da aeronave. Se estiver mesmo um pouco frouxo ou um pouco fora da posição correta, todo o voo será defeituoso. Um desses fatores é a falta de aperto e alinhamento; se o parafuso estiver frouxo ou não ajustado corretamente, pode causar muita destruição. Em qualquer caso, é realmente muito perigoso para qualquer pessoa, especialmente para quem está atrás de um avião prestes a ser lançado. Esses elementos são remodelados de forma inadequada pela aviação e devem ser realizados com muita preocupação pela indústria. Independentemente das condições climáticas, as forças armadas sempre seguem os procedimentos mais rigorosos na construção de um avião para garantir que ele seja tão seguro quanto possível.

No entanto, as peças de precisão aeroespacial são mais demandadas do que nunca, pois mais peças de alto nível estão sendo fabricadas e alguns dos materiais compostos mais avançados estão sendo utilizados. Todos esses componentes aumentam a eficiência dos aviões e sua capacidade de percorrer longas distâncias sem problemas. Não importa o quão moderno um avião possa ser, ele precisa de máquinas precisas que produzem até juntas e vedações. A Swords Precision peças de precisão aeroespacial continua melhorando à medida que novos materiais e métodos de produção mais recentes, como impressão 3D e o uso de compostos avançados, estão disponíveis. Isso também oferece maneiras de garantir a segurança dos clientes e reduzir os casos em que o veículo precisará ser levado para reparos. À medida que avançam, essas peças também tornarão o transporte aéreo mais confiável.

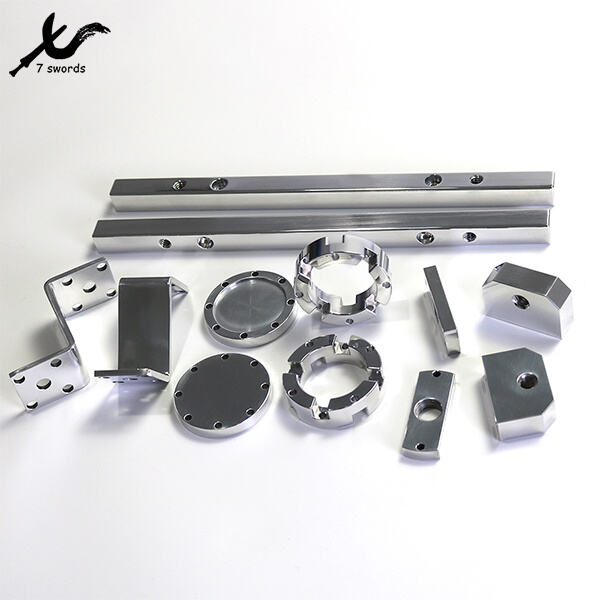

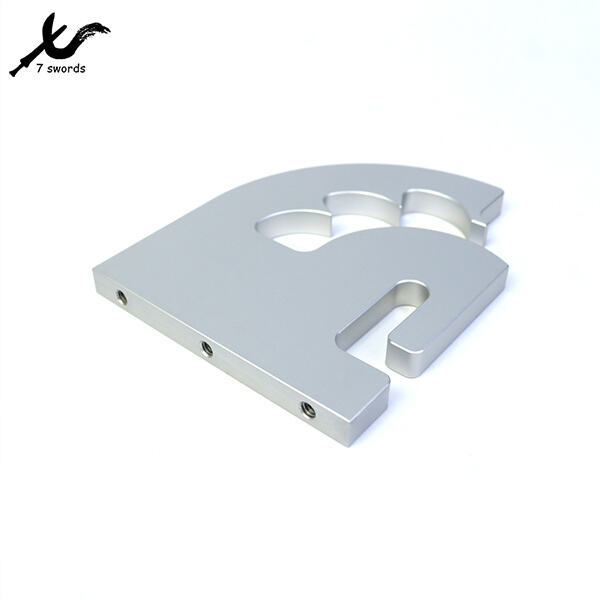

A instalação de engenharia de alta precisão aumenta a melhor qualidade das peças em um número muito grande de processos complicados. Ferramentas de máquina como fresagem CNC, torneamento CNC e similares são aplicadas na fabricação de peças com rosca e outros componentes externos de fixação com a maior precisão.

Componentes de Precisão Swords são mais ou menos as ferramentas de hoje na engenharia e fabricação de máquinas, mas as peças de Precisão Swords têm um ótimo design e capacidade de criar grandes recursos com um mínimo de margem para erros. Precisão Swords partes de precisão possuem tecnologia atualizada e padrões abrangentes para fabricar componentes que satisfarão até mesmo o cliente mais exigente. Com uma pequena adição de engenharia de precisão, não há montagem que não seja autossuficiente, onde todos os conteúdos dessa montagem estarão no lugar certo e cumprirão sua função pretendida, permitindo assim sua operação e funcionamento sem ruído.

Existem numerous peças aeroespaciais, como parafusos, por exemplo, que são pequenas e têm capacidades relativamente pequenas, e existem aquelas, como peças de motor, que são grandes e têm maior capacidade. Todas essas Swords Precision componentes de precisão precisam trabalhar bem juntas e coordenar seus esforços. Por exemplo, o motor é uma parte fundamental de um avião. Isso significa que o motor deve girar sem problemas e então funcionar poderosamente se peças de precisão, como o virabrequim, pistão do carro e outras, forem utilizadas. Essas vibrações devem estar em harmonia com o desgaste das rolamentos e a fricção, pois elas podem perturbar todo o motor e torná-lo insuportável. É por isso que é essencial que peças excelentes sejam usadas para criar o motor e tenham permanecido nessa indústria.

Assim como em qualquer negócio, a indústria aeroespacial está atenta. Novas abordagens e tecnologias podem oferecer novas possibilidades para a produção de peças de precisão e utilizá-las na fabricação. À medida que esses padrões se desenvolvem, mais e mais indústrias têm percebido as vantagens potenciais do uso da engenharia de precisão para começar a criar tais peças. Na AARC, essa tecnologia está sendo implementada para ajudar a indústria da aviação a atender às crescentes expectativas de qualidade e segurança dos consumidores. E com tanto avanço em engenharia e manufatura, você pode apostar que tudo só vai ficar melhor.

Temos o certificado ISO9001, ISO14001, ISO45001, peças de precisão aeroespacial ISO13485, aviação AS9100, automotivo IATF16949, podemos produzir peças mecânicas, peças automotivas, peças eletrônicas, peças aeroespaciais, peças de equipamentos médicos, peças de equipamentos de comunicação, peças de nova energia, peças de construção e produtos domésticos.

Serviços OEM e ODM são oferecidos Peças de precisão para Aerospace, quantidade é 1 peça. Oferecemos orçamentos dentro de três horas. A produção de amostras requer de 1 a 3 dias. A entrega em grande escala pode levar de 7 a 14 dias. Nossa capacidade de produção mensal excede 300.000 peças.

Oferecemos uma variedade de equipamentos de produção, que vão desde máquinas de 4-eixos, 3-eixos e peças de precisão para Aerospace. Oferecemos uma ampla gama de capacidades de processamento, incluindo torneamento, fresagem e usinagem, perfuração e EDM e Impressão 3D. Trabalhamos com uma variedade de materiais diferentes, incluindo alumínio, latão, cobre, aço inoxidável, compostos e plásticos, fabricando peças que podem atender a qualquer exigência industrial.

Nossa equipe de engenharia de peças de precisão para Aerospace está disponível 24/7 e pronta para responder a quaisquer perguntas que você possa ter. Eles são altamente qualificados e têm a experiência necessária para resolver suas preocupações. Peças personalizadas com tolerâncias de precisão elevada: +/-0,01 mm, Espaço especial: +/-0,005 mm.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Política de Privacidade—Blog