Building 49, Fumin Industrial Park, Pinghu Village, Longgang District

Sunday Closed

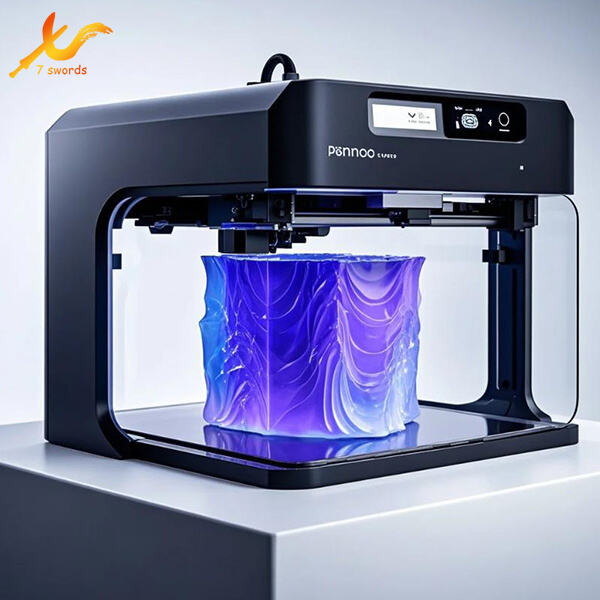

Hello, have you ever heard of 3D printing? It is a very neat technology that enables individuals to construct three-dimensional-object by depositing material in successive layers. Using 3D printing, you can manufacture a wide variety of objects, from toys, to vehicles, and even homes! It's like magic! But are you aware of resins 3D printing? This is a complexion of 3D printing that is redefining manufacturing in many great ways.

Resins 3D printing is something in its infancy stage and an exciting technique, it is a way for printing objects with a higher detail and more strength than ever before. It is made of an epoxy material that is a type of plastic called resin. This resin is a very special resin because it can be molded into literally anything your brain desires. Heating this resin and then cooling it causes the material to harden into a solid object, which we can use in multiple ways. This is what sets resins 3D printing apart from types of manufacturing.

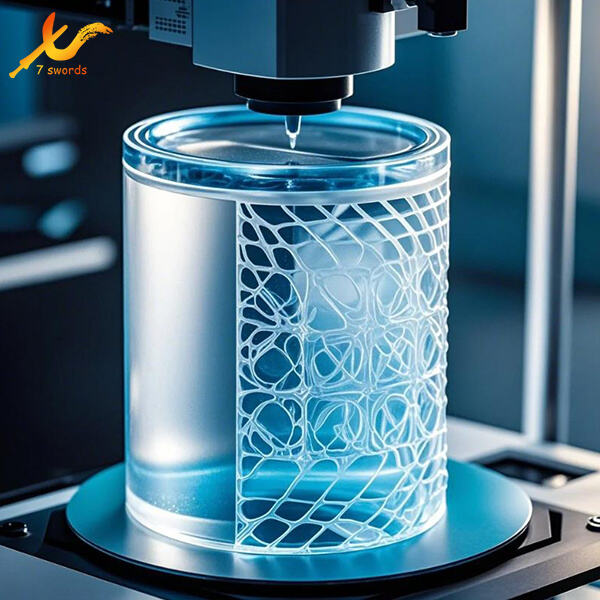

Resins 3D printing is one of the most detailed and customized designs people can 3D print on. Because the resin can be formed into such varied shapes, designers can create objects that are difficult to produce using conventional manufacturing processes. This allows them to produce things that are really unique and special. For instance, if you were going to do something like a toy version of your favorite character with some features that nobody else had This is the power of resins 3D printing!

3D Printed Resins are quickly proving to be of tremendous assistance across multiple areas and realms of industry. In the medical industry, it crafts perfect prosthetic limbs and other medical needs for every patient. This is huge because every one body is different, and having the fit tailored can change someone's whole life. In the automotive industry, it makes components that are lighter and more robust, which improve vehicle performance. It is also used in clothing to make something unique in gypsy jewelry and the latest accessories.

There are tons of good and exciting reasons to try resins 3D printing for your next project. The first main reason resin 3D printing allows you to make very detailed and specific designs, meaning that your parts can be unique and unlike anything else. Moreover, resin-based 3D printing is more eco-friendly than conventional manufacturing techniques because it requires less material and generates less waste. This helps keep our planet healthy. Lastly, resins 3D printing is usually faster and less expensive than traditional manufacturing, allowing you to complete your project sooner and saving money you can always use!

We offer OEM and ODM services Minimum quantity of orders is one piece resins 3d printing are sent within three hours Sample production requires 1 to 3 days and bulk delivery can take 7 to 14 days Our production capacity for the month is more than 300 000 pieces

Our production equipment includes 3-axis (4-axis), 5-axis, up to 6-axis machines. We have a broad range of processing capabilities, including turning, milling, grinding, drilling as well as resins 3d printing, 3D Printing. We can work with a range of materials, including copper, aluminum, brass and stainless steel, plastics, composites and crafting components that meet any industrial need.

resins 3d printing professional engineering team is always on the move, waiting to respond quickly to your queries. They are highly skilled and have the experience to address your concerns. Custom parts with high precision tolerances: +/-0.01 mm, Special area: +/-0.005 mm.

We have ISO9001 certificate, resins 3d printing, ISO45001, medical ISO13485, aviation AS9100, Automobile IATF16949, we can produce mechanical parts, automobile parts, electronic parts, aerospace parts, medical device parts, communication equipment parts, new energy parts, construction and household products parts.

Copyright © Shenzhen Perfect Precision Products Co., Ltd. All Rights Reserved — Privacy Policy — Blog